Thread guiding ring for a spinning machine or a twisting machine

A wire guide and winding machine technology, applied in textiles and papermaking, etc., can solve problems such as wire winding, and achieve the effect of prolonging the service life and avoiding wiping off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

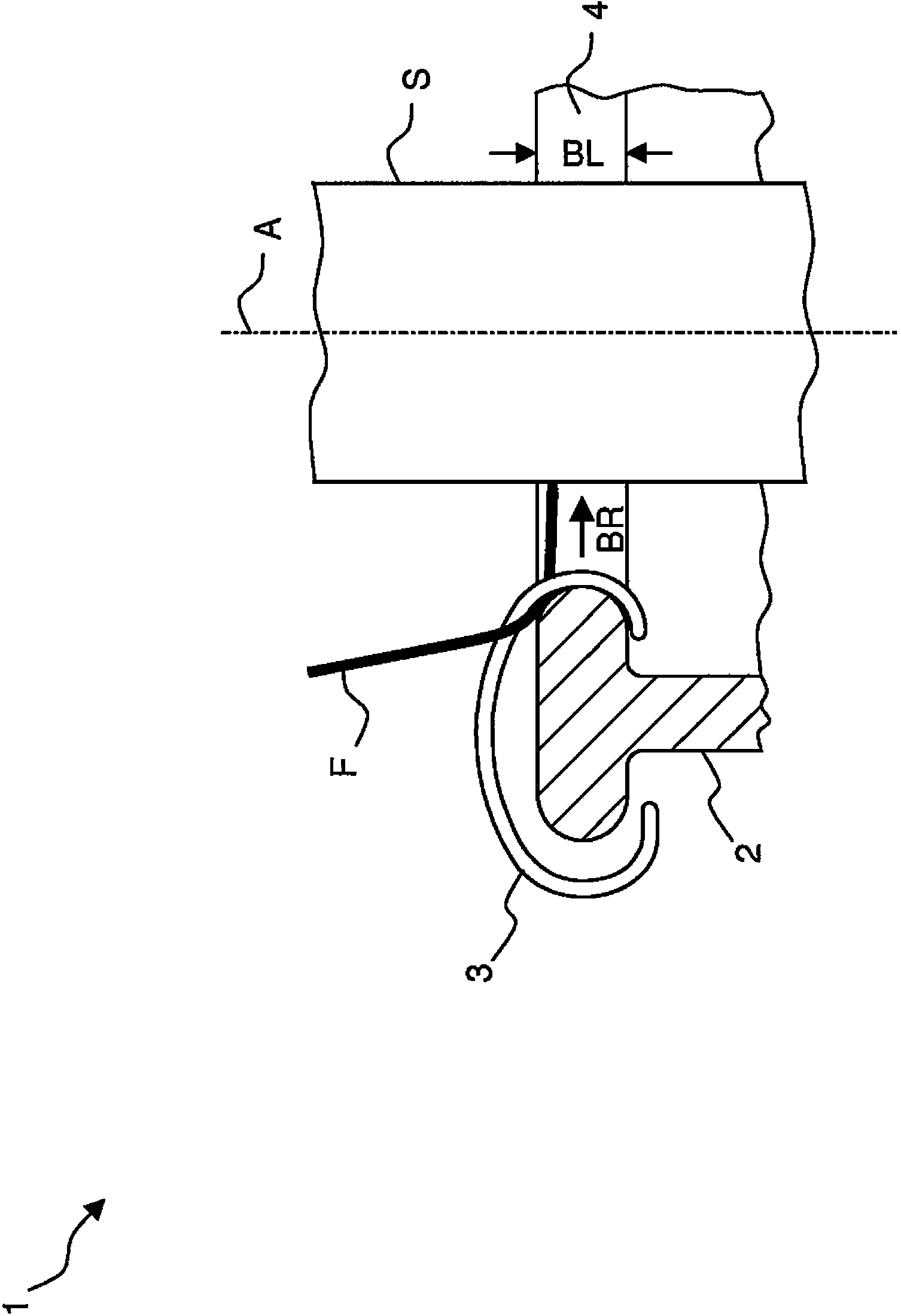

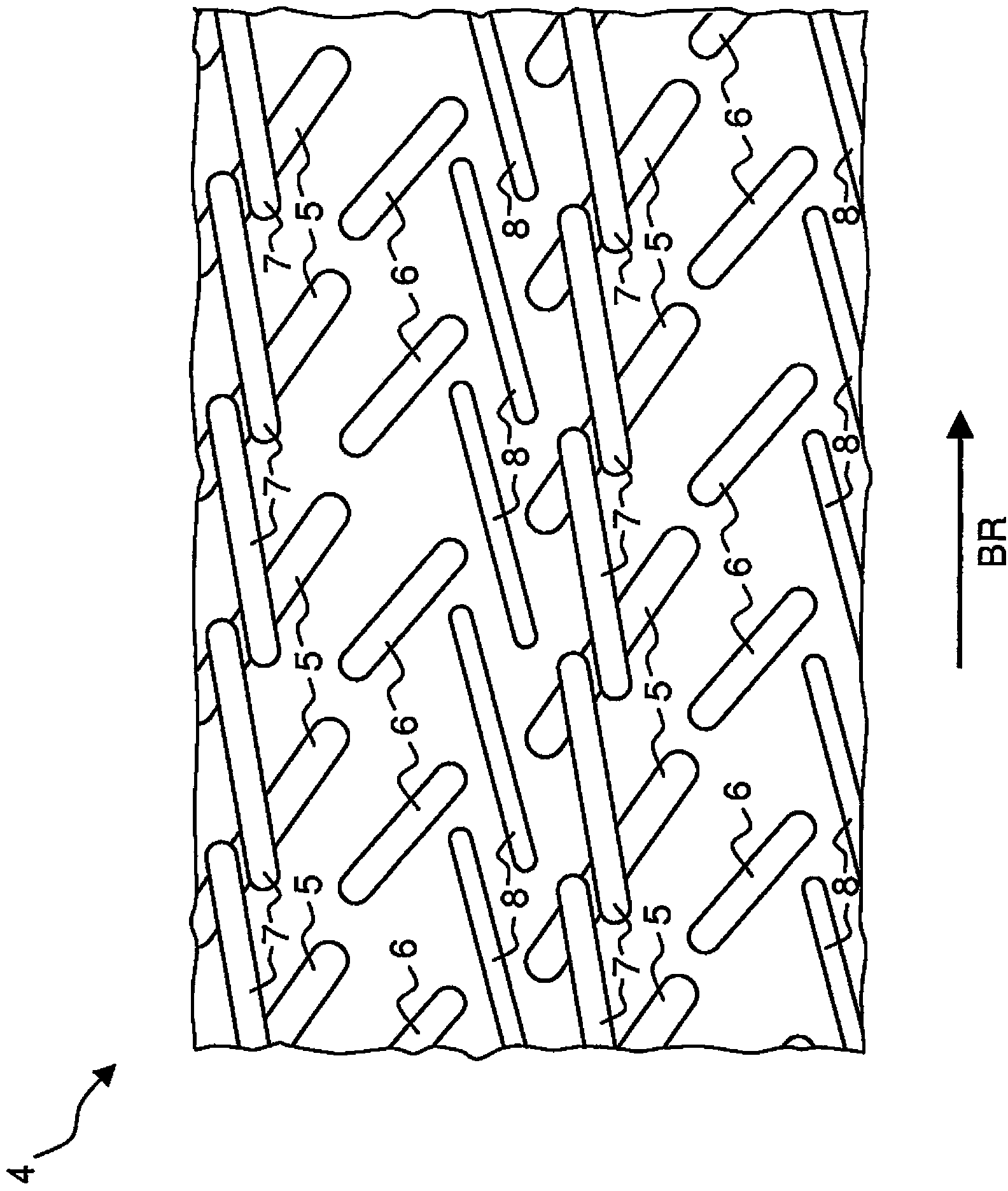

[0039] figure 1 An exemplary embodiment of a winding device 1 of a ring spinning machine with a thread guide ring 2 according to the invention is shown schematically. The winding device 1 is used for winding the wire F to be moved onto the reel S. FIG. A reel S, which is actively driven to rotate about a vertical axis A, is mounted concentrically and rotationally fixed on a spindle (not shown). For this purpose, the wire guide ring 2 is likewise arranged concentrically. The annular movement 3 is attached to the thread guide ring 2 in such a way that it can move circumferentially around the reel S in the provided direction of movement BR. Furthermore, the thread guide ring 2 has a running surface 4 along which the annular movement part 3 can slide. The working surface 4 is assigned to the roll S and has a width BL.

[0040] The wire F fed from the top by the axial direction is hung on the annular moving part 3 so that the wire F is reversed and fed to the spool S substantia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com