Mixed crystal phase catalytic cracking flue gas sulfur transfer agent prepared by secondary growth method and its application

A technology of catalytic cracking and mixed crystal phases, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve the problems of reducing the number of desulfurization active centers of sulfur transfer agents and the decline in the function of silica to enhance strength, etc., to achieve Enhanced desulfurization effect and service life, good desulfurization activity, widening composition range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

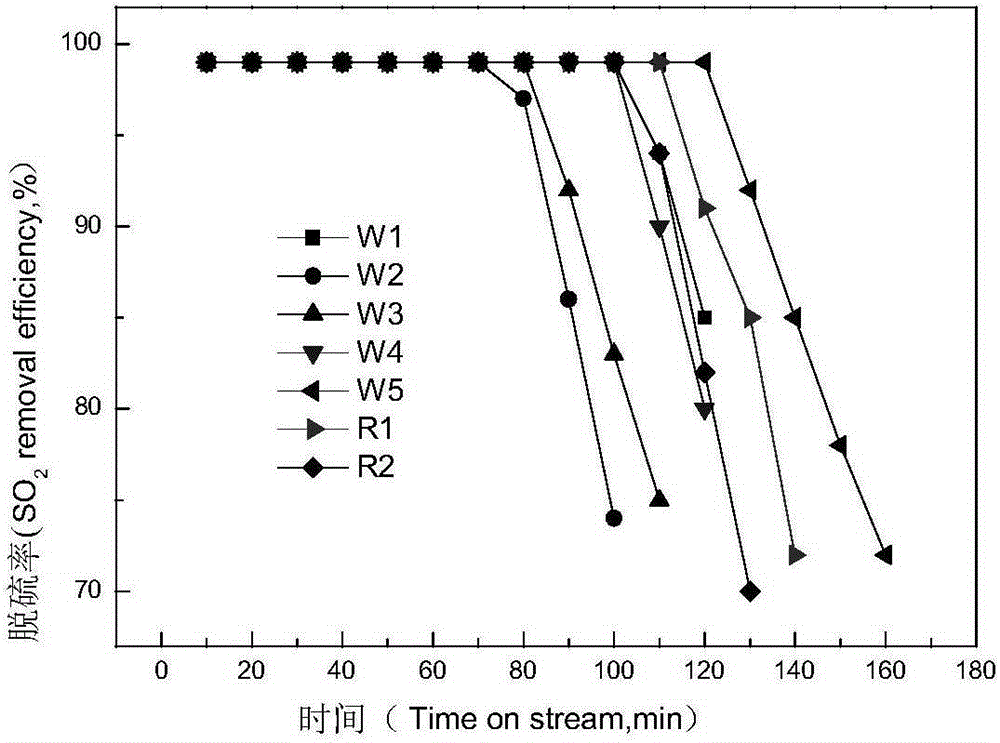

Embodiment 1

[0040] 43.77gMgSO 4 , 30.16gTi(SO 4 ) 2 9H 2 O, 15.15gFe(NO 3 ) 3 9H 2 O, 9.06gCu(NO 3 ) 2 ·3H 2 O dissolved in 200gH 2 In O, prepare solution A, and stir at room temperature (to make the slurry rotate rapidly, but not so that the slurry flies out of the beaker) for 4 hours; dissolve 30g NaOH in 200gH 2 In O, configure solution B; add solution A dropwise to solution B heated in a vigorously stirred 60°C water bath, continue stirring for 4 hours after the addition is complete, to obtain slurry C, and keep the pH value of the slurry ≥ 10 during the entire mixing process , put the slurry C into a reaction kettle with a polytetrafluoroethylene liner, crystallize at 80°C for 18h, then cool, suction filter, wash until neutral, dry at 120°C for 10h, and roast at 700°C for 2h to obtain the intermediate product Z1; 16.8gAlCl 3 Dissolve in 20ml of deionized water to obtain solution D, and impregnate solution D on Z1 by multiple impregnation methods of equal volume, then dry a...

Embodiment 2

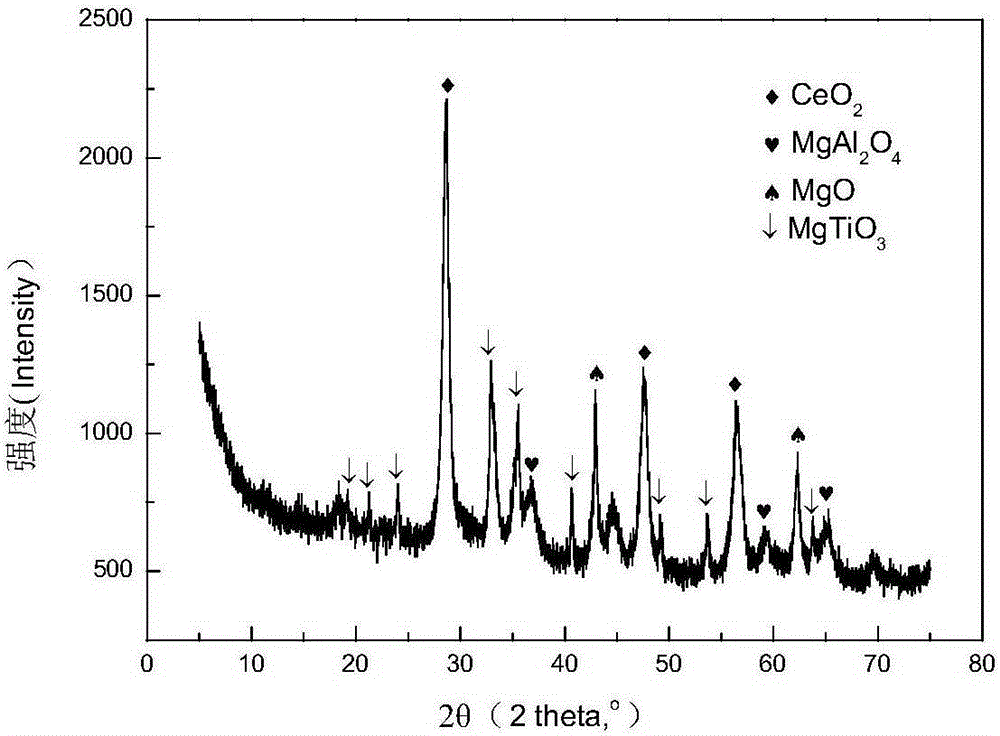

[0042] 22.8gMgSO 4 , 11.4gMg(NO 3 ) 2 ·6H 2 O, 9.58gMgCO 3 , 40.24gTi(SO 4 ) 2 9H 2 O, 15.15gFe(NO 3 ) 3 9H 2 O, 6.78gCe(NO 3 ) 3 ·6H 2 O dissolved in 200gH 2 O, prepared as solution A, and stirred at room temperature for 4h; 30gNaOH, 10gKOH were dissolved in 200gH 2 In O, configure solution B; add solution A dropwise to solution B heated in a vigorously stirred 60°C water bath, continue stirring for 4 hours after the addition is complete, to obtain slurry C, and keep the pH value of the slurry ≥ 10 during the entire mixing process , Put the slurry C into a reaction kettle with a polytetrafluoroethylene liner, crystallize at 90°C for 20h, then cool, filter with suction, wash until neutral, dry at 120°C for 10h, and roast at 800°C for 2h to obtain the intermediate product Z2; 30.21gAl 2 (SO 4 ) 3 Dissolve in 50ml of deionized water to obtain solution D, and impregnate solution D on Z2 by multiple impregnation methods of equal volume, then dry at 120°C for 10h, ...

Embodiment 3

[0044] 30.13gMgCl 2 ·6H 2 O, 38.54gC 4 h 6 o 4 Mg·6H 2 O, 47.12gC 16 h 36 o 4 Ti, 6.77gSr(NO 3 ) 2 , 3.67gZn (NO 3 ) 2 ·6H 2 O was dissolved in 200g of absolute ethanol, prepared as solution A, and stirred at room temperature for 4h; 25gNaOH, 15gKOH, 8gNaCO 3 Soluble in 200gH 2 In O, configure solution B; add solution A dropwise to solution B heated in a vigorously stirred 60°C water bath, continue stirring for 4 hours after the addition is complete, to obtain slurry C, and keep the pH value of the slurry ≥ 10 during the entire mixing process , put the slurry C into a reaction kettle with a polytetrafluoroethylene liner, crystallize at 70°C for 17h, then cool, suction filter, wash until neutral, dry at 110°C for 10h, and roast at 800°C for 2h to obtain the intermediate product Z3; 16.8gAlCl 3 Dissolve in 20ml of deionized water to obtain solution D, and impregnate solution D on Z3 by multiple impregnation methods of equal volume, then dry at 120°C for 10h, and b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com