Filter bag pull-up type reciprocating oscillation discharge type centrifugal machine

A centrifuge and filter bag technology, which is used in centrifuges, centrifuges with rotating drums, etc., can solve the problems of incomplete removal of filter cakes, inconvenient production and application, and negative impact on increasing operating costs. The effect of complete removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

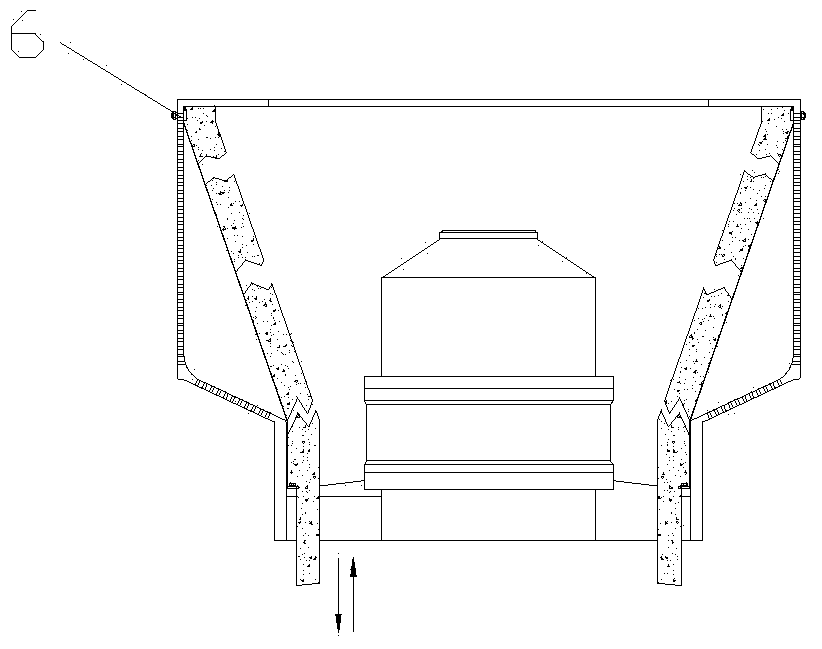

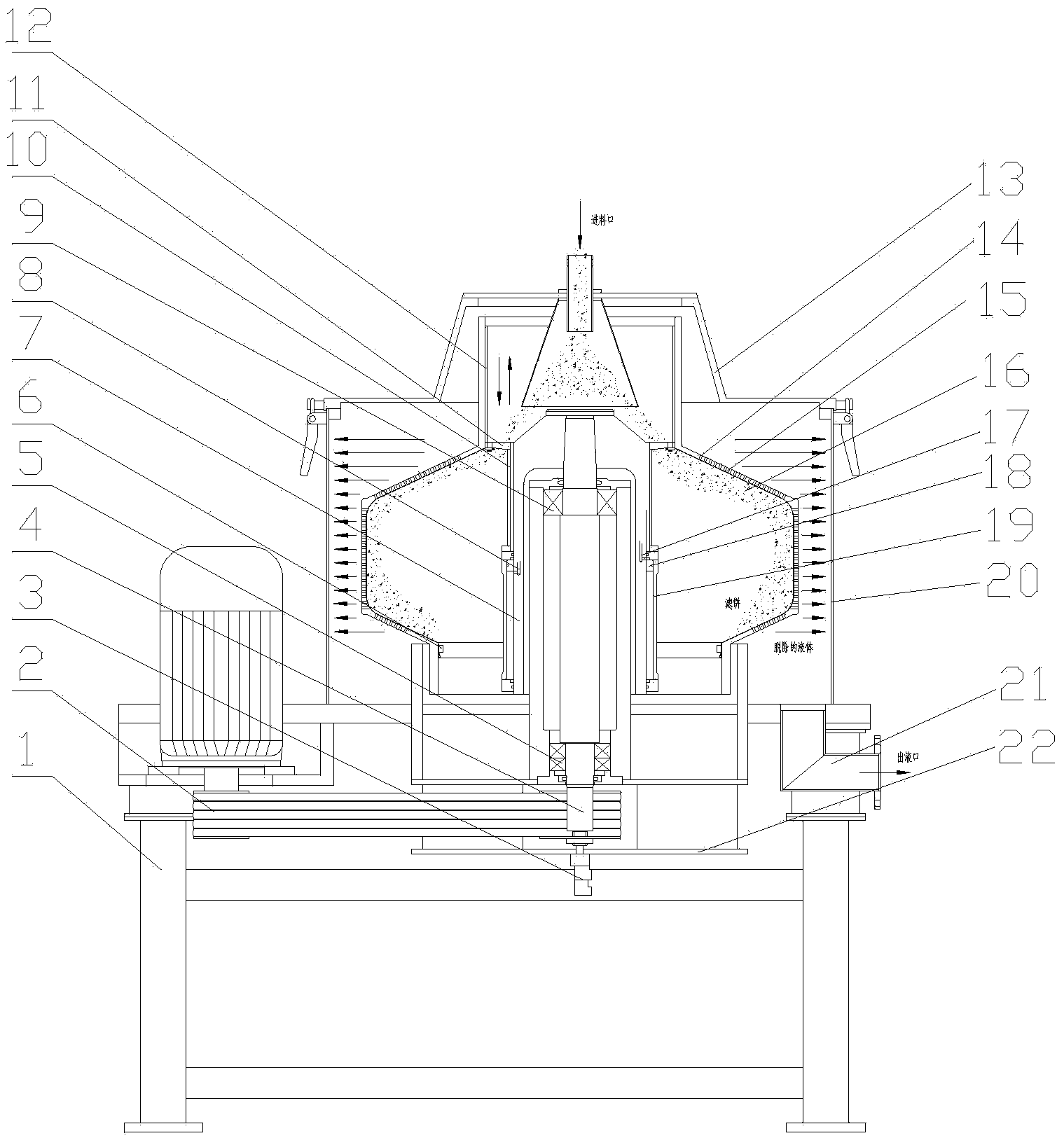

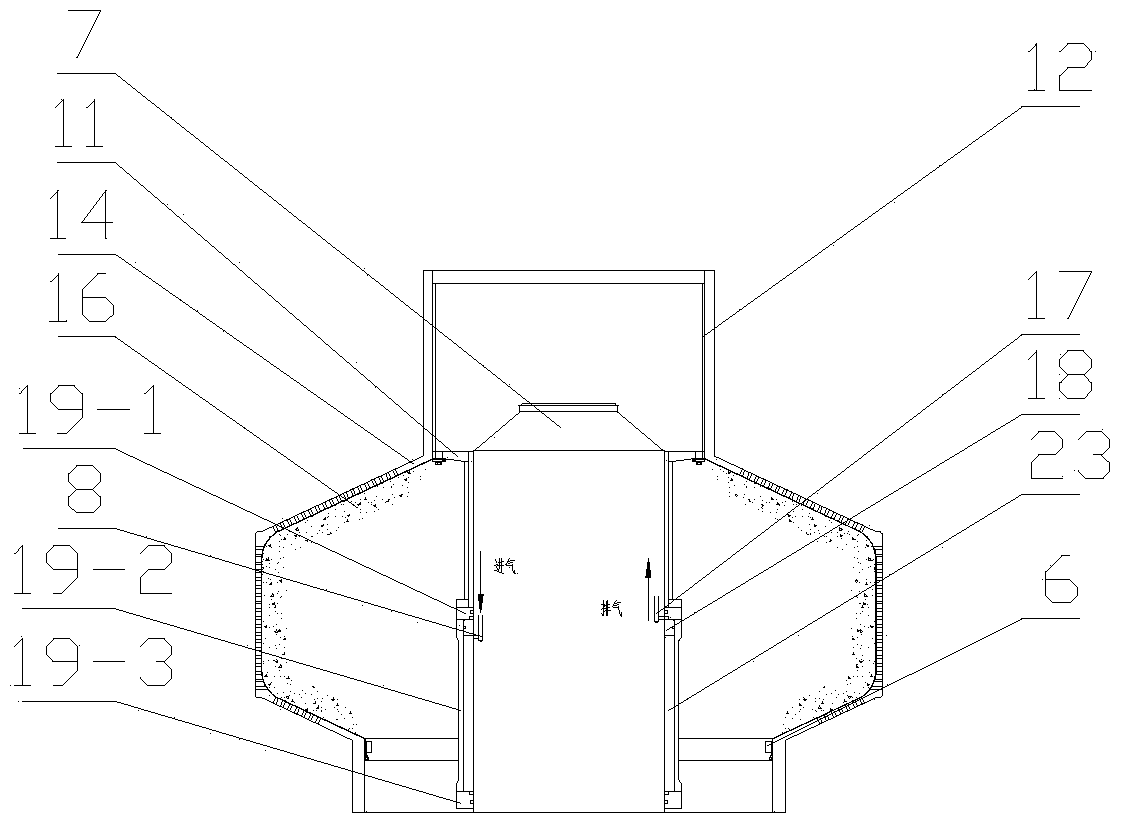

[0021] Example: Combined Figure 2-5 , the filter bag pull-up type reciprocating oscillating discharge type centrifuge of the present embodiment, it comprises:

[0022] Frame 1, a cylindrical shell 20 is fixed on the bottom plate of the frame, and a hollow drum 14 driven by a power mechanism is set in the cylindrical shell, and the drum 14 is an upper column section-upper cone section-middle column section -Five-segment composite vertical structure of the lower cone section-lower column section, wherein the walls of the upper cone section, middle column section, and lower cone section have holes, the inner diameter of the upper column section is the smallest, the inner diameter of the middle column section is the largest, and the inner diameter of the lower column section is larger than The inside diameter of the upper column.

[0023] In the specific setting, the diameter of the upper column section is the smallest, and no holes are opened on the column wall. The inner diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com