Sorting machine for surface appearances of clamping plates

A technology of sorting machines and splints, applied in sorting and other directions, can solve problems such as manual handling, achieve the effect of improving reliability and eliminating accidental errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

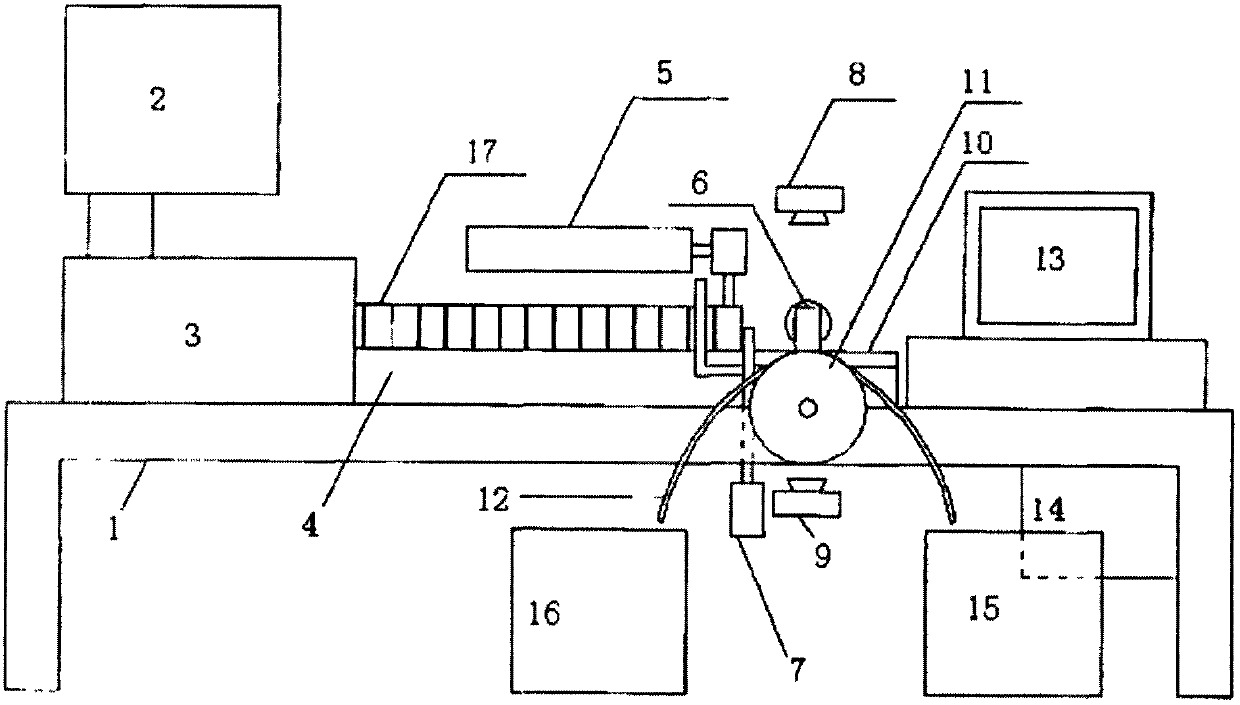

[0021] Such as figure 1 As shown, a splint surface sorting machine mainly includes: a bench 1, a plywood storage box to be sorted 2, a vibration arrangement mechanism 3, a splint arrangement track 4, a splint feeding mechanism 5, a splint withdrawal mechanism 6, and a splint positioning mechanism. Mechanism 7, top camera 8, bottom camera 9, transparent glass 10, sorting wheel 11, blanking plate 12, computer 13, electric control box 14 and other parts.

[0022] The splint apparent sorter can sort two faces at a time. Before sorting, the vibrating plate of the vibration arrangement mechanism vibrates and arranges the two faces to be sorted in the up and down direction. The splint enters the camera area and exits the camera area using cylinder action. Pushing, splint appearance screening adopts camera photography, computer image data analysis and other technical processing. According to the computer processing results, the sorting wheel rotates in different directions to send goo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com