Horizontal type aluminum grating extruder

A technology of extruding machine and grating, which is applied in the field of product extrusion and aluminum grating extruding machine, which can solve the problems of low efficiency, high energy consumption, and laboriousness, and achieve strong safety, energy saving and humanization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

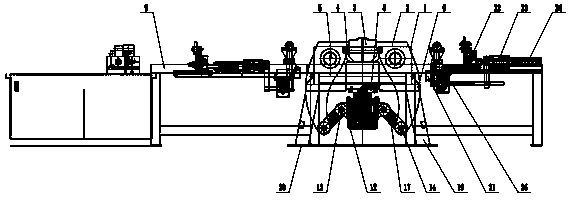

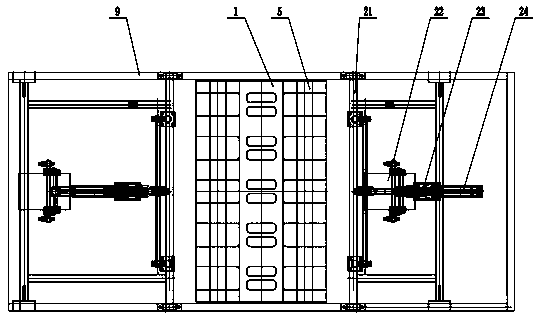

[0017] Example 1, see figure 1 , 2 , 3, 4, the bottom plate 20 is welded with the body leg 19, the top plate 6 is welded to the body leg to form the body base; the body 1 is placed on the body base, the extrusion leg 2 is connected to the body 1 with the main shaft 5, and the connecting Rod 17 is connected with extruding leg 2 with axle 14;

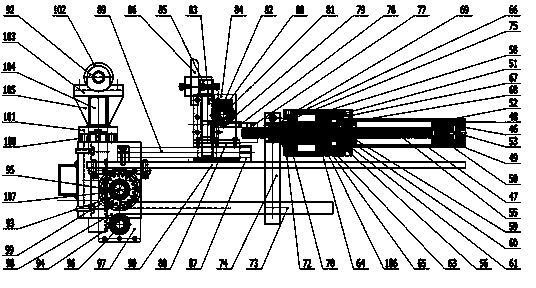

[0018] Process the first oil cylinder block 40, the first piston 42, the first piston rod 30, install the third seal ring 38, the first seal ring 35 and the support ring 43 on the first piston 42; put the first O-ring 44 and the second O-ring 45 are installed on the first piston rod 30, the second back cap 41 is installed on the first piston rod 30, and the first piston 42 and the first piston rod 30 are put into the first cylinder body together 40, install the second sealing ring 37, the dustproof ring 33 and the first compound sleeve 36 on the first guide sleeve 34, install the first guide sleeve 34 on the first cylinder block 40, ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com