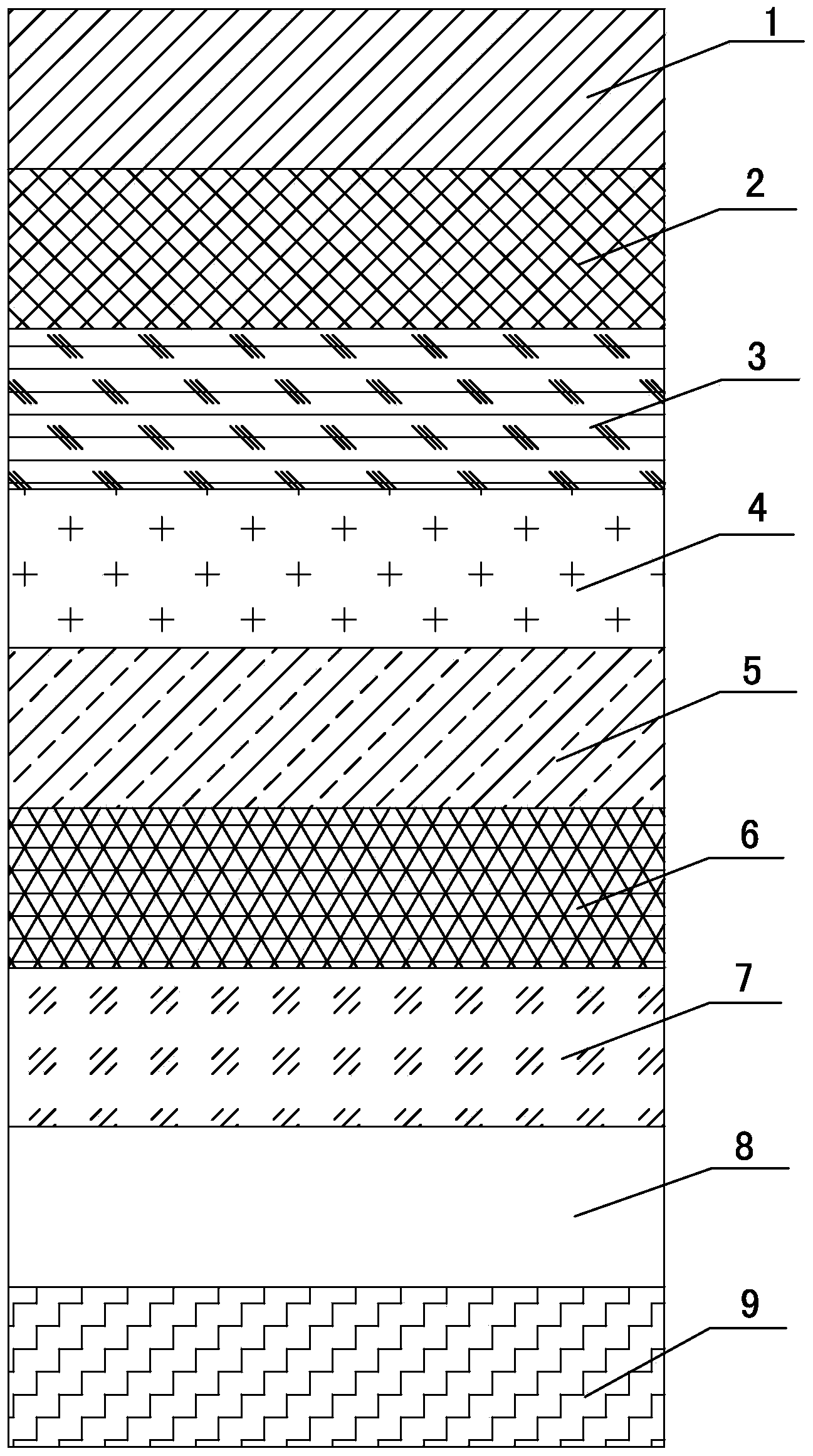

Colorful holographic numerical code information thermoprint foil and preparation method thereof

A hot stamping foil, digital technology, applied in printing, printing process, temperature recording method, etc., can solve the problem of easy copying of digital information, achieve high information carrying capacity and randomness, increase applicability, and protect interests.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] 500,000 pieces:

[0062] (1) Choose 18μm PET as the base material,

[0063] (2) Release layer formula: 5017 water wax (20%): 1.2kg; water: 13kg; ethanol: 18kg; use 190-mesh anilox coating roller, wet coating amount: 4.7g / m 2 . The operating speed is 700 rpm. Drying tunnel temperature: 100°C, coating speed: 110m / min.

[0064] (3) Imaging layer, formula: 802 resin: 6kg; 902 resin: 1.2kg; butanone: 3kg; MIBK: 1kg; anilox roller: 170 mesh; wet coating amount: 6g / m 2 , drying temperature: 90°C; production speed: 100m / min (hot air heating)

[0065] (4) Holographic image layer, using a pH value of 4 and a density of 31g / cm 3 The electroforming liquid is used to produce nickel plates, and a holographic image layer is formed by molding with a molded gravure integrated machine. The molding temperature is 185°C and the pressure is 0.25Mpa.

[0066] (5) The formula of the gravure printing ink protective layer is as follows: 10 kg of SXB-0720 washing ink, 1 kg of water and 1 k...

Embodiment 2

[0076] 1 million pieces:

[0077] (1) Choose 12μm PET as the base material,

[0078] (2) Release layer formula 5017 water wax (20%): 1.7kg; water: 13kg; ethanol: 23kg. Use 180-mesh anilox coating roller, wet coating amount: 4.3g / m 2 . Speed 500 rpm. Drying tunnel temperature: 80°C, coating speed: 100m / min.

[0079] (3) Coating the imaging layer, the formula is as follows:

[0080] 802 resin: 7kg; 902 resin: 1.8kg; butanone: 4kg; MIBK: 1.4kg. Coating process: anilox roller: 150 mesh; wet coating amount: 5.5g / m 2 .

[0081] Drying temperature: 120°C, production speed: 50m / min (infrared heating).

[0082] (4) Holographic image layer

[0083] The pH value is 3.9 and the density is 28g / cm 3 The electroforming solution is used to produce nickel plates, the molding temperature is 150°C, and the pressure is 0.3Mpa.

[0084] (5) Gravure printing ink protective layer formula: SXB-0720 washing ink 17 kg, water and alcohol 1.5 kg each. Gravure roll: 220 mesh; drying temperat...

Embodiment 3

[0093] 2 million pieces:

[0094] (1) Choose 20μm PET as the base material,

[0095] (2) Release layer formula: 5017 water wax (20%): 2kg; water: 15kg; ethanol: 25kg.

[0096] Use 200-mesh anilox coating roller, wet coating amount: 4.9g / m 2 . Speed 1000 rpm. Drying tunnel temperature: 150°C; coating speed: 150m / min.

[0097] (3) Coating the imaging layer, the formula is as follows:

[0098] 802 resin: 8kg; 902 resin: 2kg; butanone: 4.5kg; MIBK: 1.5kg. Coating process: anilox roller: 250 mesh; wet coating amount: 6.5g / m 2 .

[0099] Drying temperature: 135°C, production speed: 100m / min (hot air heating).

[0100] (4) Holographic image layer

[0101] Use a pH value of 3.7 and a density of 32g / cm 3 The electroforming liquid is used to produce nickel plates, and a holographic image layer is formed by molding with a molded gravure integrated machine. The molding temperature is 190°C and the pressure is 0.35Mpa.

[0102] (5) The formula of the gravure printing ink prote...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com