Support component of automobile roof lining and side curtain air bags

A technology for car roofs and supporting components, applied in the field of auto parts, can solve the problems of heavy weight, high parts and vehicle assembly costs, and achieve the effect of weight reduction and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

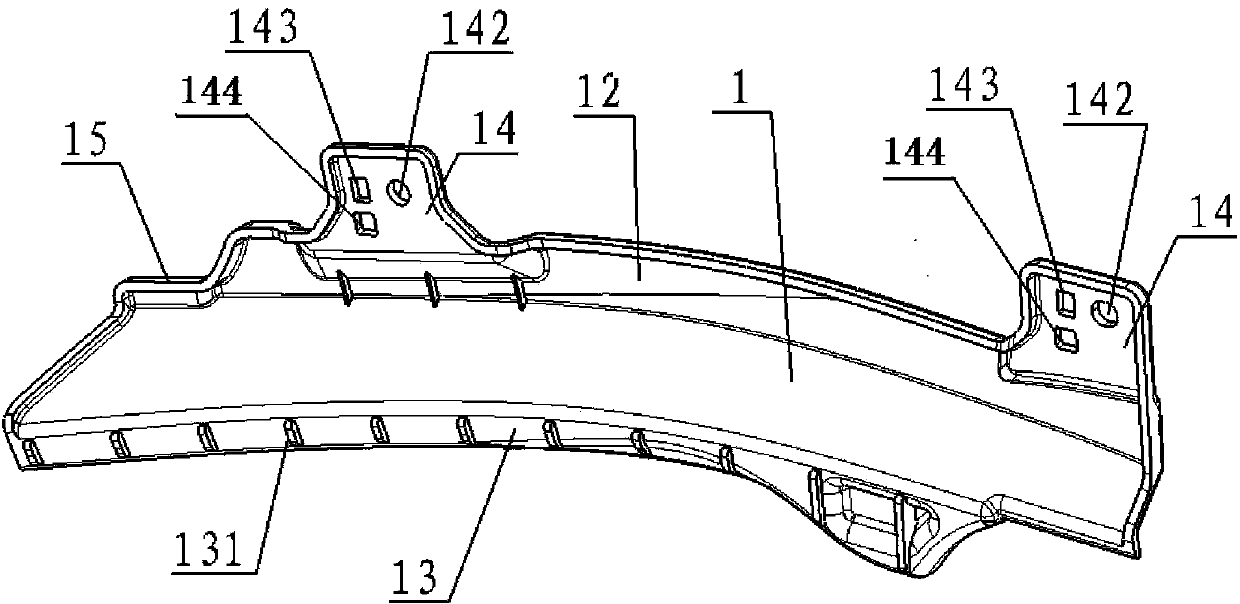

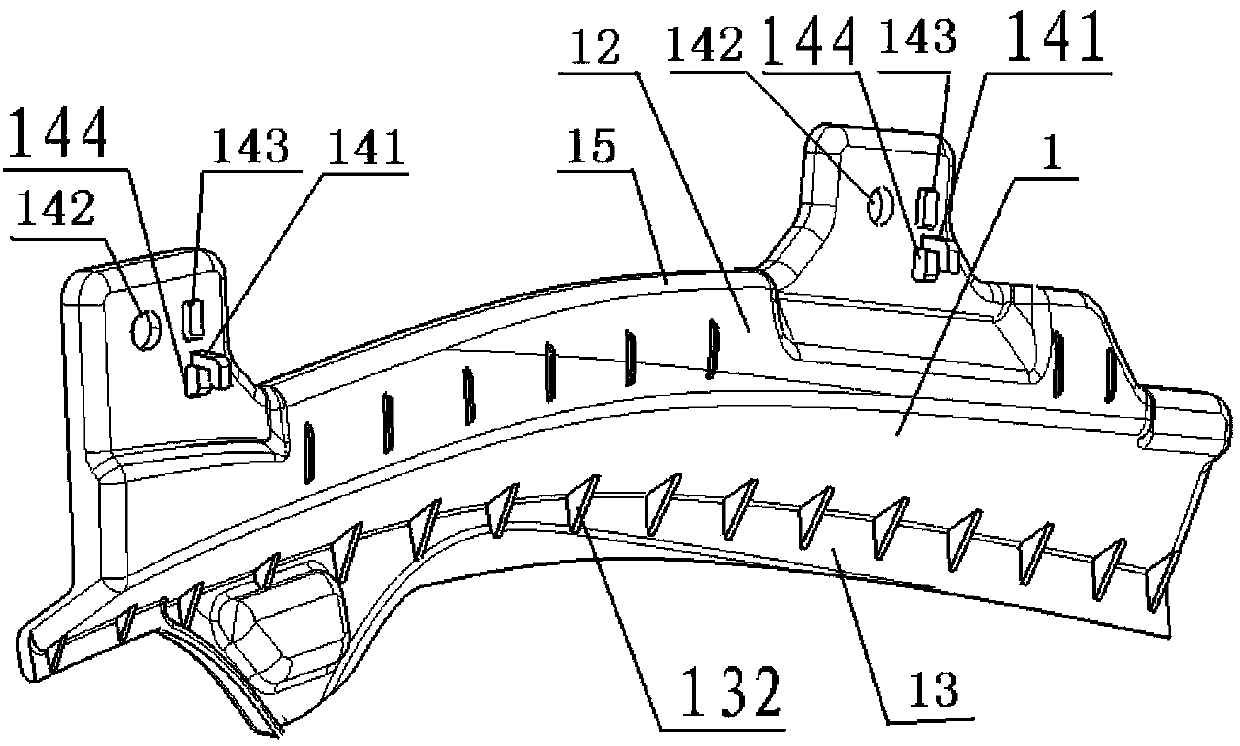

[0023] Figure see figure 1 with figure 2 The supporting member for the roof lining and side air curtain shown in the car includes a support body 1 made of plastic and molded by injection molding. Side 12, a lower flange 13 bent downward is provided on the lower side of the supporting body 1;

[0024] A square bump 14 is respectively provided on the left and right parts of the upper flange 12, and a round hole 142, a first square hole 143 and a second square hole 144 are respectively arranged on each of the square bumps; A downwardly bent hook-shaped structure 141 is respectively provided on the edge behind the two second square holes 144;

[0025] A plurality of evenly distributed vertical reinforcing ribs 131 are arranged on the front of the lower flange 13 , and a plurality of evenly distributed triangular reinforcing ribs 132 are arranged on the bending part of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com