Worm wheel spiral elevator

A technology of screw lifts and worm gears, applied to lifting devices, mechanical equipment, belts/chains/gears, etc., can solve problems such as inconvenience, and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, characteristics and features of a worm wheel screw elevator proposed according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. Efficacy, detailed as follows.

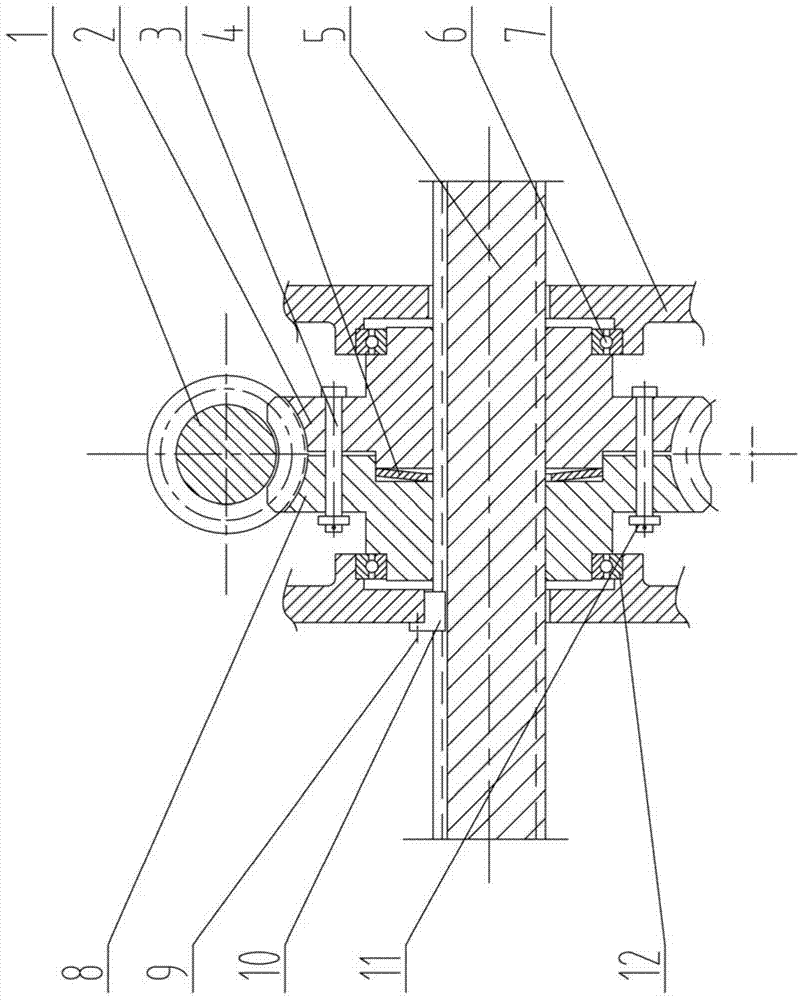

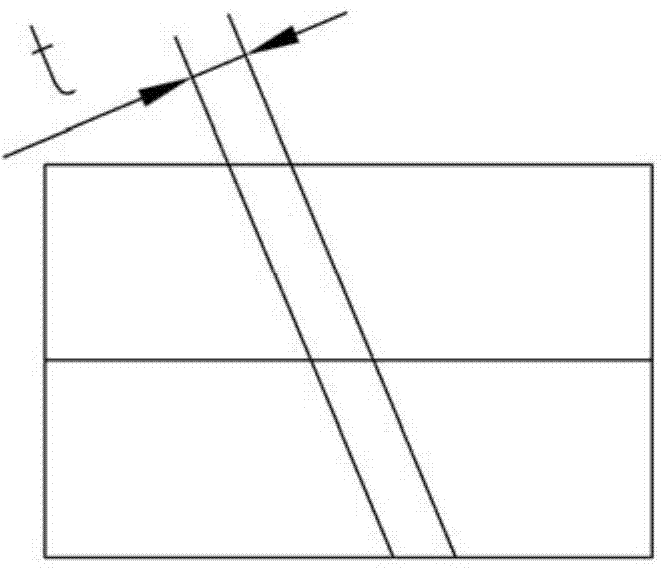

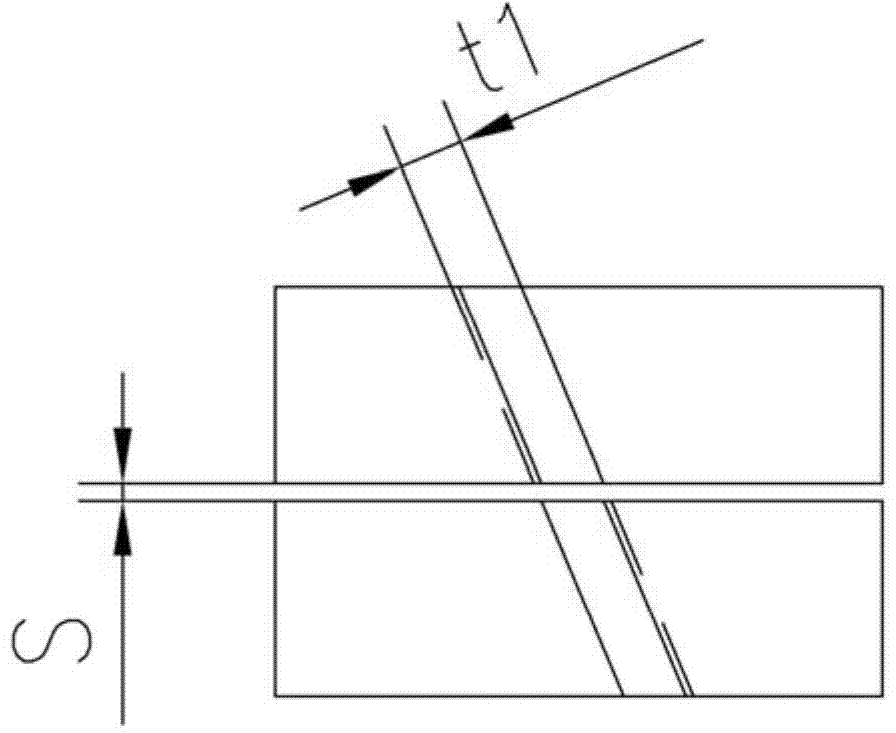

[0031] see figure 1 , Figure 2A , Figure 2B as shown, figure 1 It is a structural schematic diagram of a worm gear screw jack of the present invention. Figure 2A It is a schematic diagram of tooth thickness variation of a convex-concave worm gear in close contact with a worm gear screw jack of the present invention. Figure 2B It is a schematic diagram of tooth thickness variation when the convex and concave worm gears of a worm gear screw jack are separated when they are separated.

[0032] The present invention proposes a worm gear screw jack, comprising: wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com