Method for preparing high-strength wear-resistant glass-ceramic by using iron tailings

A technology for glass-ceramics and iron tailings, which is applied in the field of preparing high-strength and wear-resistant glass-ceramics by using iron tailings, can solve the problems of high cost, reducing the density of glass-ceramics, mechanical properties and service performance, and complicated processes, and achieves the The effect of reducing the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1. A method for preparing high-strength wear-resistant glass-ceramics using iron tailings, followed by the following steps:

[0030] 1) Ingredients:

[0031] The raw materials are composed of the following parts by weight: 35 parts of iron tailings, 25 parts of quartz, 10 parts of magnesium carbonate, 15 parts of alumina, 3 parts of calcium oxide, 6 parts of titanium oxide, 5 parts of boron oxide, and 1 part of antimony oxide.

[0032] 2). The above raw materials are mixed by mechanical ball milling, and the ball milling time is 6 hours;

[0033] 3). Melt the mixed raw materials obtained in step 2) at 1450~1500℃ for 4 hours;

[0034] 4) Press or calender the molten glass to prepare plate glass (length, width, and thickness are 100mm, 40mm, and 5mm, respectively);

[0035] 5) Send the above-mentioned plate glass to an annealing furnace for annealing, at an annealing temperature of 580°C, and cool down in the furnace after annealing for 1 hour; obtain annealed glass;

[0036]...

Embodiment 2

[0038] Example 2. A method for preparing high-strength wear-resistant glass-ceramics using iron tailings,

[0039] The ingredients are:

[0040] The raw materials are composed of the following parts by weight: 40 parts of iron tailings, 20 parts of quartz, 12 parts of magnesium carbonate, 13 parts of alumina, 4 parts of calcium oxide, 7 parts of titanium oxide, 3 parts of boron oxide, and 1 part of antimony oxide.

[0041] The preparation method is the same as in Example 1.

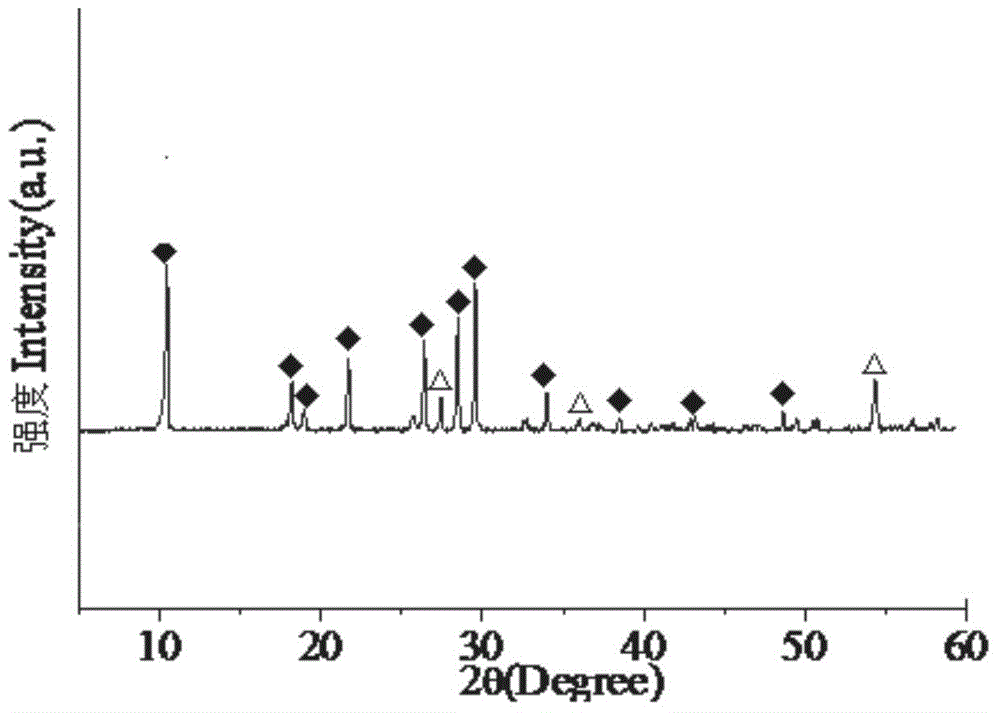

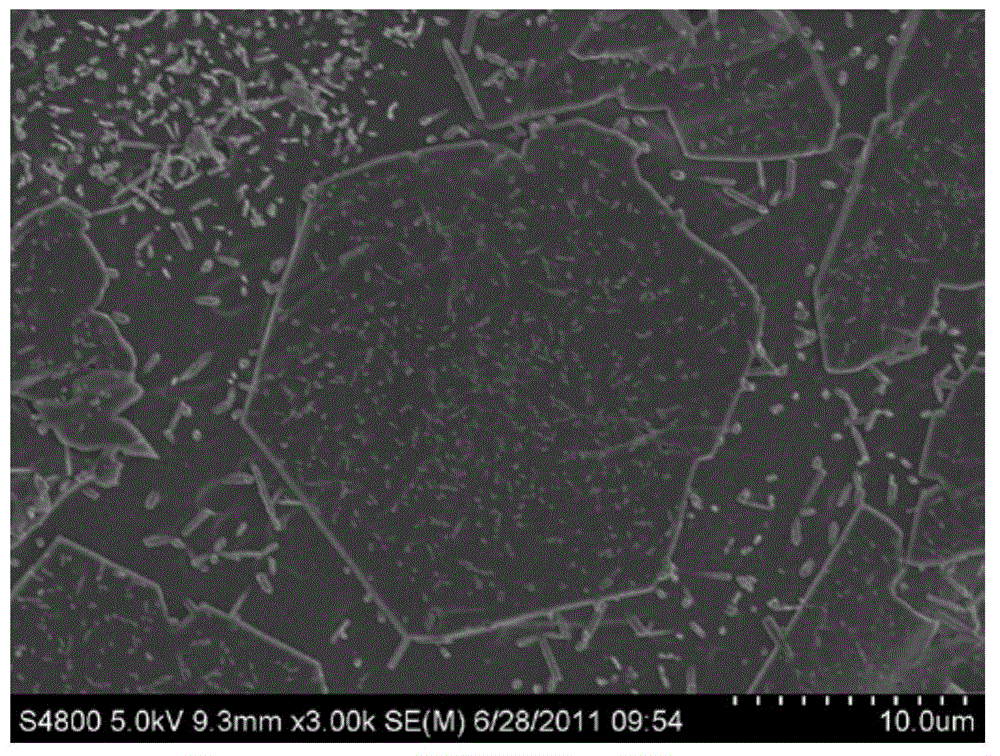

[0042] The main crystal phase of the prepared glass-ceramic product is cordierite with hexagonal crystal phase, the crystal grain size is about 10 microns, the whole is crystallized, the appearance is black, the gloss is good, the Vickers hardness ≥ 8.2 GPa, the flexural strength ≥ 125 MPa .

Embodiment 3

[0043] Example 3: A method for preparing high-strength wear-resistant glass-ceramics using iron tailings,

[0044] The ingredients are:

[0045] The raw materials are composed of the following parts by weight: 37 parts of iron tailings, 23 parts of quartz, 11 parts of magnesium carbonate, 14 parts of alumina, 4 parts of calcium oxide, 6 parts of titanium oxide, 4 parts of boron oxide, and 1 part of antimony oxide.

[0046] The preparation method is the same as in Example 1.

[0047] The main crystal phase of the prepared glass-ceramic product is cordierite with hexagonal crystal phase, the crystal grain size is about 10 microns, the whole is crystallized, the appearance is black, the gloss is good, the Vickers hardness is ≥8.8GPa, and the flexural strength is ≥134MPa .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com