Secondary smoke trapping device for buffering type rotary furnace

A secondary flue gas and converter technology, which is applied in the direction of manufacturing converters, improving process efficiency, improving energy efficiency, etc., can solve problems such as increased operating costs, unsatisfactory energy conservation and emission reduction, and increased initial investment in equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

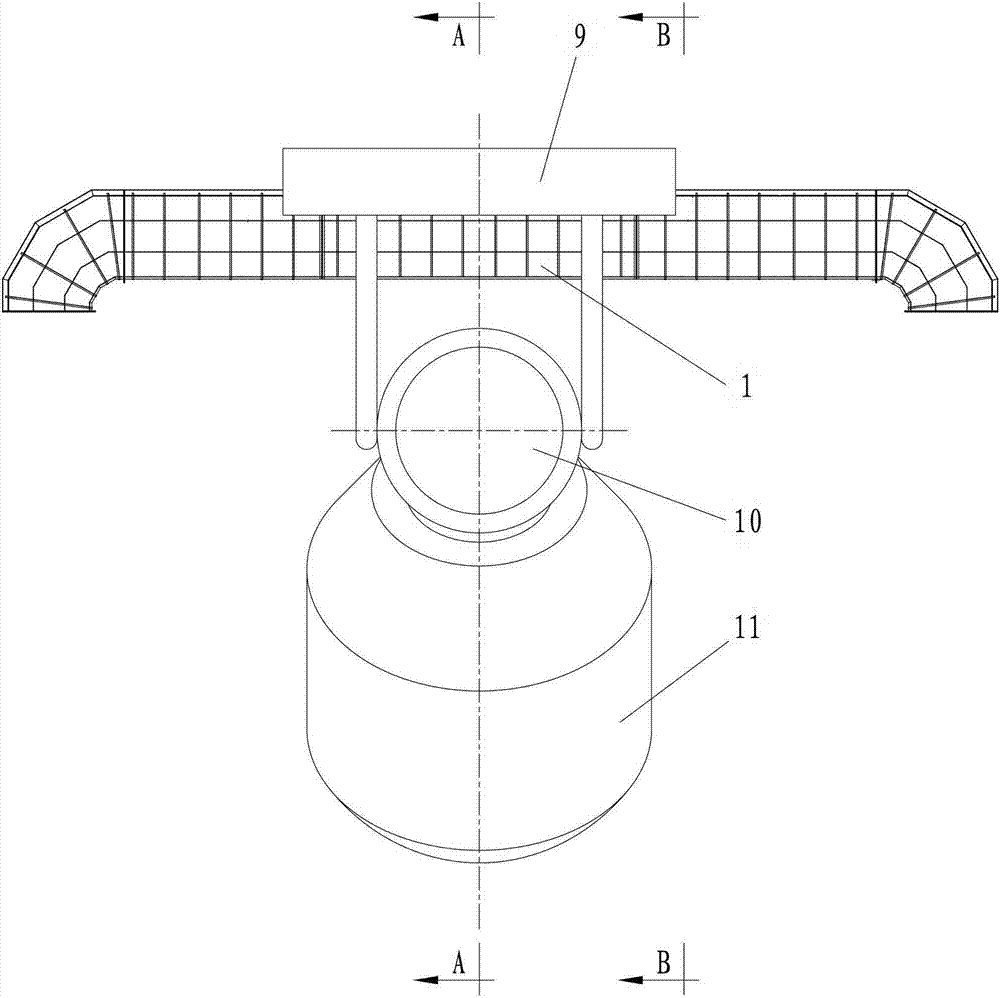

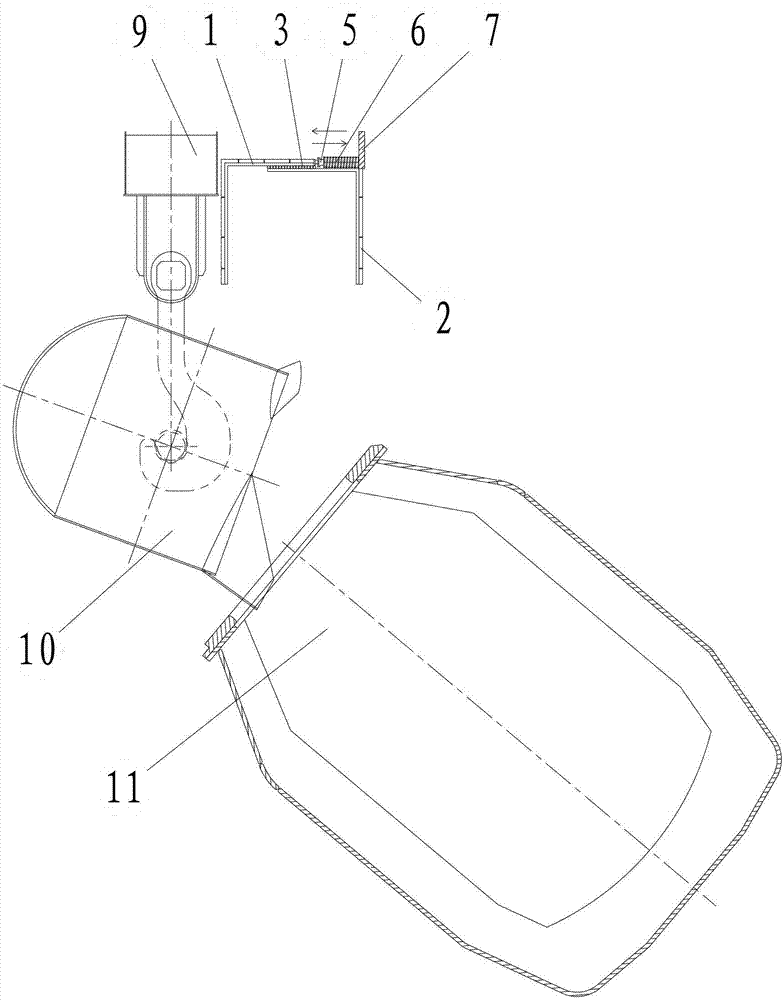

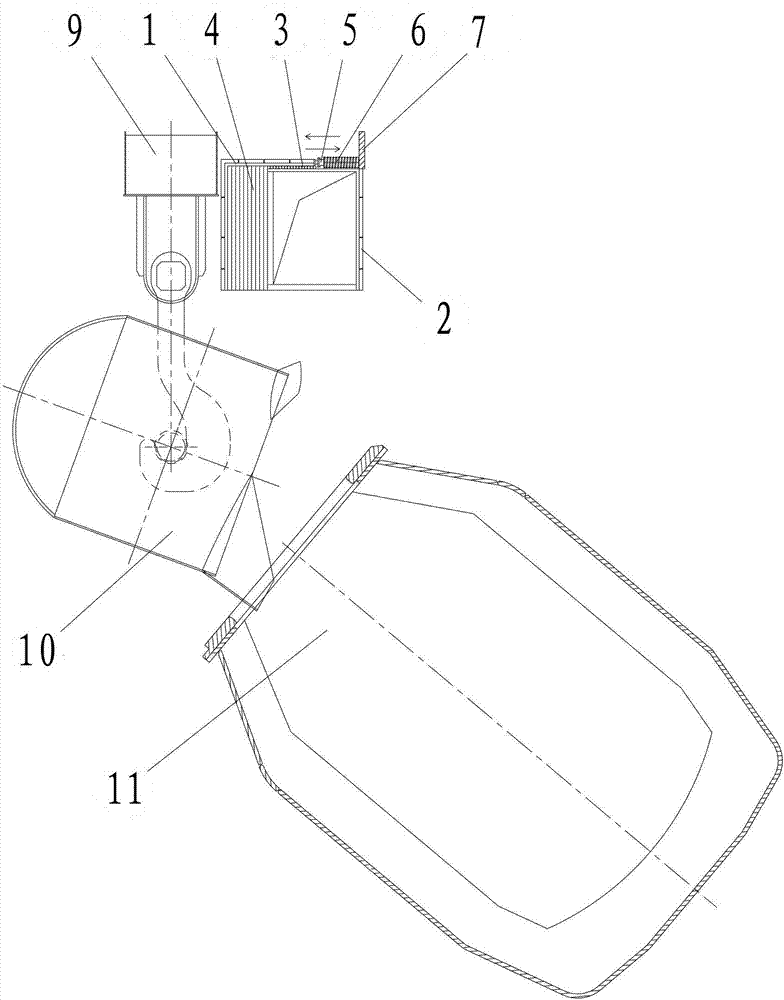

[0018] Such as figure 1 , 2 , 3, 4, a buffer type converter secondary flue gas capture device, including a gas collecting pipe provided with a gas collecting port, and a buffer; the buffer is an inverted L shape with a movable front plate 1; the gas collecting pipe is rectangular Cavity 2, the bottom surface of rectangular cavity 2 and one side are respectively provided with a mouth, and two mouths combine to form an opening, and the two ends of rectangular cavity 2 communicate with air duct 8 respectively; so that the mouth on the bottom surface can be aligned with the furnace mouth of the converter 11, the other side of the movable front plate 1 is connected to one end of the spring 6 through the connecting device 5, and the other end of the spring 6 is fixed to the fixed plate 7 on the top surface of the rectangular cavity 2 Connection, a slide rail device 3 is provided between the movable front plate 1 and the top surface of the rectangular cavity 2, when the movable fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com