Atomic layer deposition device

A technology of atomic layer deposition and exhaust pipe, applied in coating, metal material coating process, gaseous chemical plating, etc., can solve the problems of atomic layer deposition device becoming larger and difficult to maintain the uniformity of gas injection pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Embodiments of the present invention will be described in detail below with reference to the drawings. However, the present invention is not limited or limited to the Examples. The same reference numerals shown in the respective drawings denote the same components.

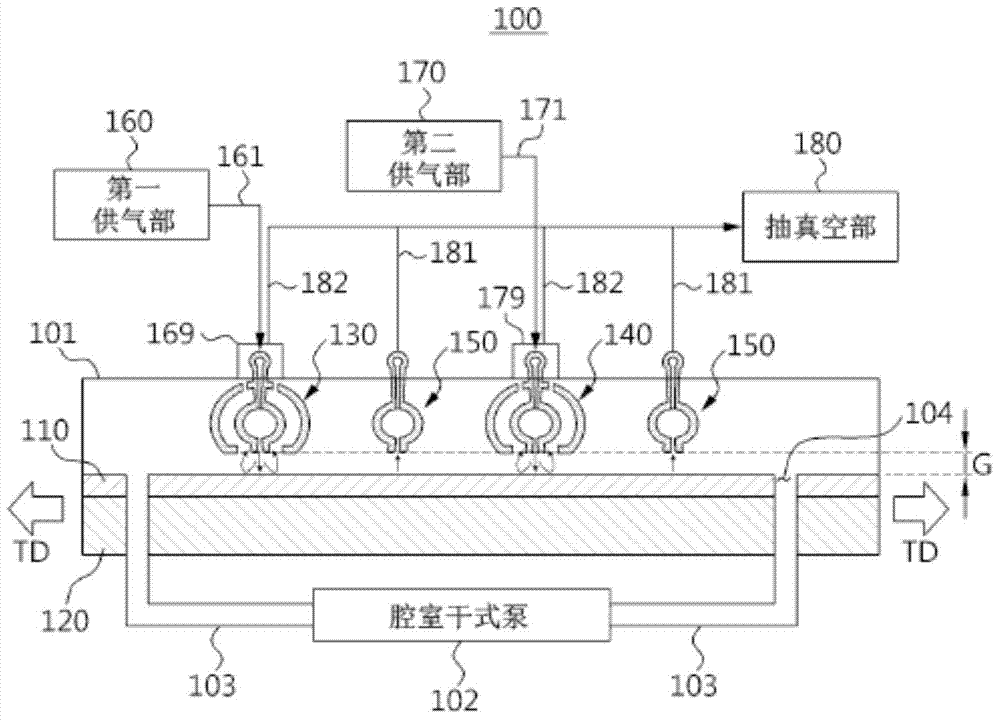

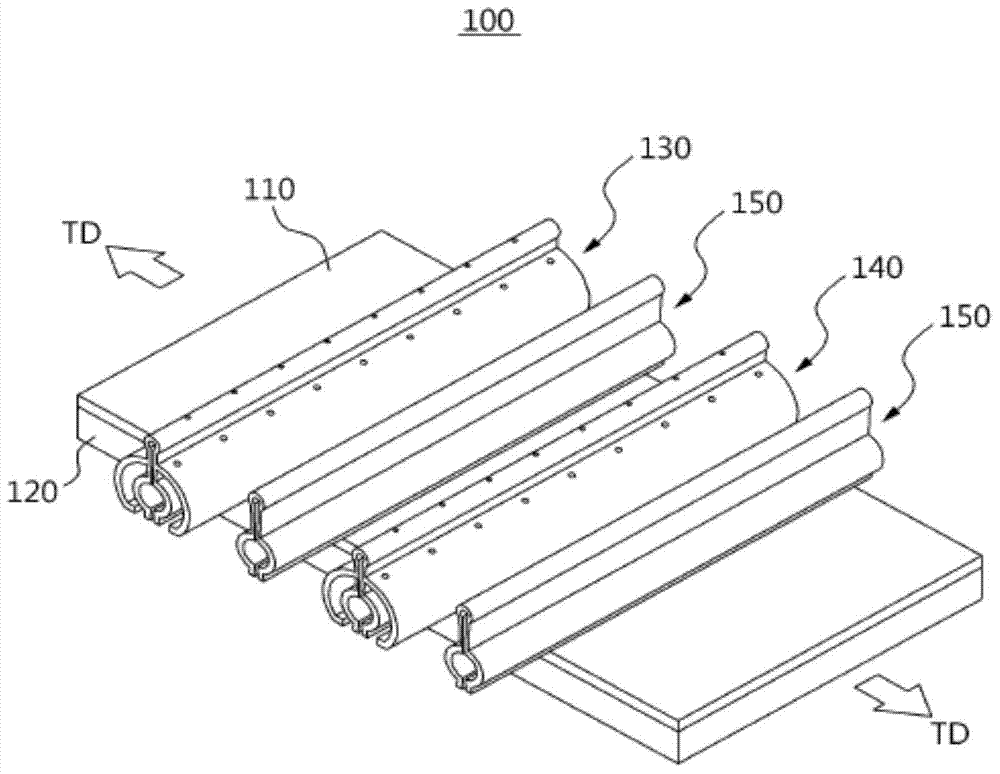

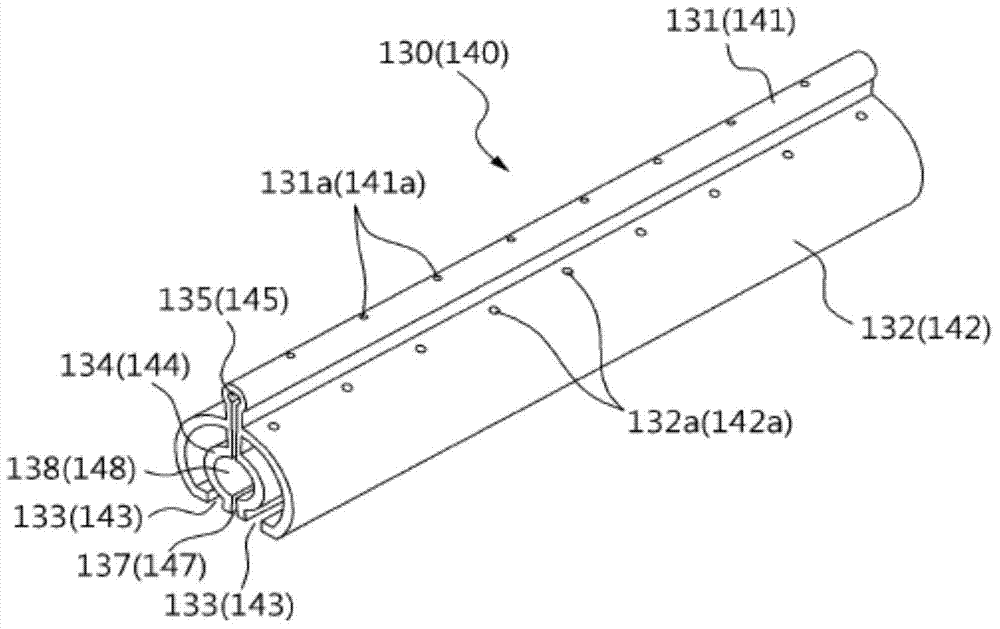

[0045] figure 1 is a diagram schematically showing an atomic layer deposition apparatus according to an embodiment of the present invention, figure 2 yes means figure 1 A perspective view of the interior of an atomic layer deposition apparatus, image 3 is for figure 1 A perspective view of the gas extraction unit of the atomic layer deposition device, Figure 4 Yes image 3 Transverse and longitudinal cross-sectional views of the gas suction and discharge unit, Figure 5 yes means figure 1 A perspective view of the gas suction unit of the atomic layer deposition device and the gas injection pressure adjustment unit connected to the gas suction unit, Image 6 Yes Figure 5 The cross-sectional vie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com