A Retrofitting Method for Retaining Wall of Front Slope of Pillar Abutment

A column-type abutment and retaining wall technology, applied in excavation, water conservancy projects, artificial islands, etc., can solve problems such as no relevant research, achieve the effect of reducing project cost and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention is described in detail below in conjunction with specific example:

[0051] The present invention is divided into three stages:

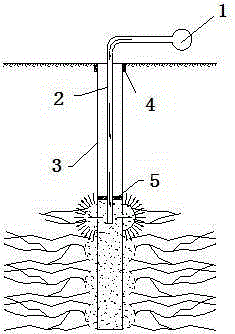

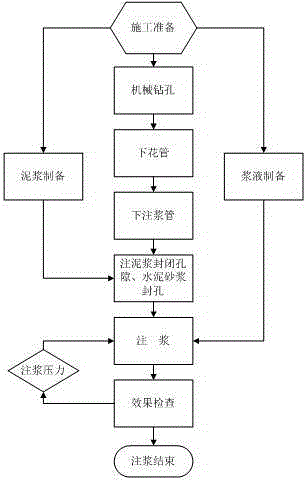

[0052] The first stage is the splitting and grouting reinforcement of the abutment fill soil.

[0053] The construction area is determined according to the on-site pouring experiment and stability analysis results (corresponding to the distribution of plastic regions and the position of the sliding surface in the ultimate failure state), and is divided into the reinforcement construction area and the reinforcement affected area. The reinforcement construction area is the layout range of the drilling. The area affected by reinforcement is the range where the grout splits the soil; the details are as follows:

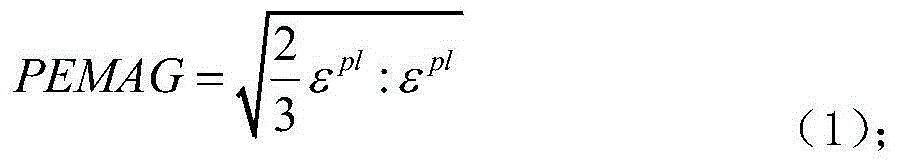

[0054](1-1) The active earth pressure reinforcement construction area behind the wall is determined based on the PEMAG(F t =1.61), the area range is 7.5m behind the platform and the depth is 10m.

[0055] The exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com