Annular hydraulic cylinder

A ring-shaped hydraulic cylinder and hydraulic cylinder technology are applied in the field of hydraulic cylinders to achieve the effects of easy manufacture, compact structure and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

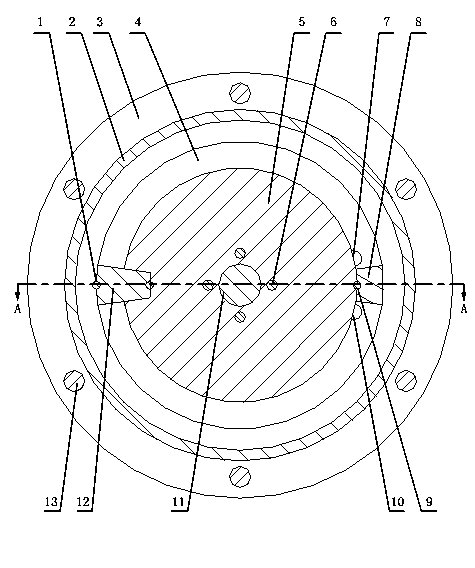

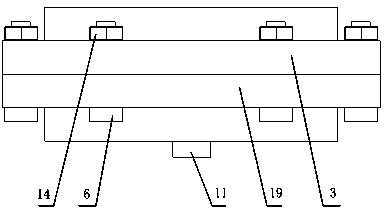

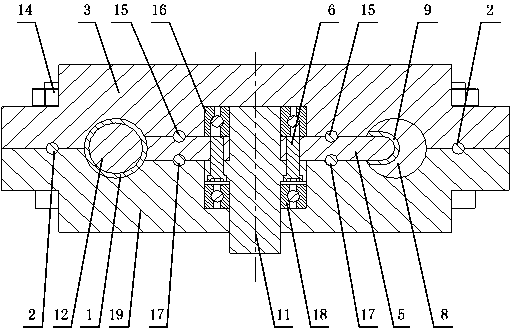

[0036] Below in conjunction with accompanying drawing, the present invention is further described: as Figure 1-15 As shown, a ring-shaped hydraulic cylinder is composed of an upper end cover 3, a hydraulic cylinder oil chamber 4, a lower end cover 19, an annular piston rod 5, a piston 12, a fixed stopper 8 and an output shaft 11;

[0037] Such as figure 1 with figure 2 As shown, the upper end cover 3 and the lower end cover 19 are connected by six bolts 13 and nuts 14 uniformly distributed around the circumference. Such as image 3 As shown, the hydraulic cylinder oil chamber 4 is composed of the upper end cover 3 and the lower end cover 19, and the first sealing ring 2 is used to seal between the upper end cover 3 and the lower end cover 19.

[0038] Such as figure 1 As shown, the fixed block 8 is affixed to the inner wall of the hydraulic cylinder oil chamber 4, the fixed block 8 is in motion with the annular piston rod 5, the piston 12 is affixed to the annular piston...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com