A water medium coupler and its internal pressure relief method

A coupling and water medium technology, applied in the direction of functional valve type, fluid transmission device, safety valve, etc., can solve problems such as troubles, achieve good sealing effect, and prevent the leakage of working water and gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

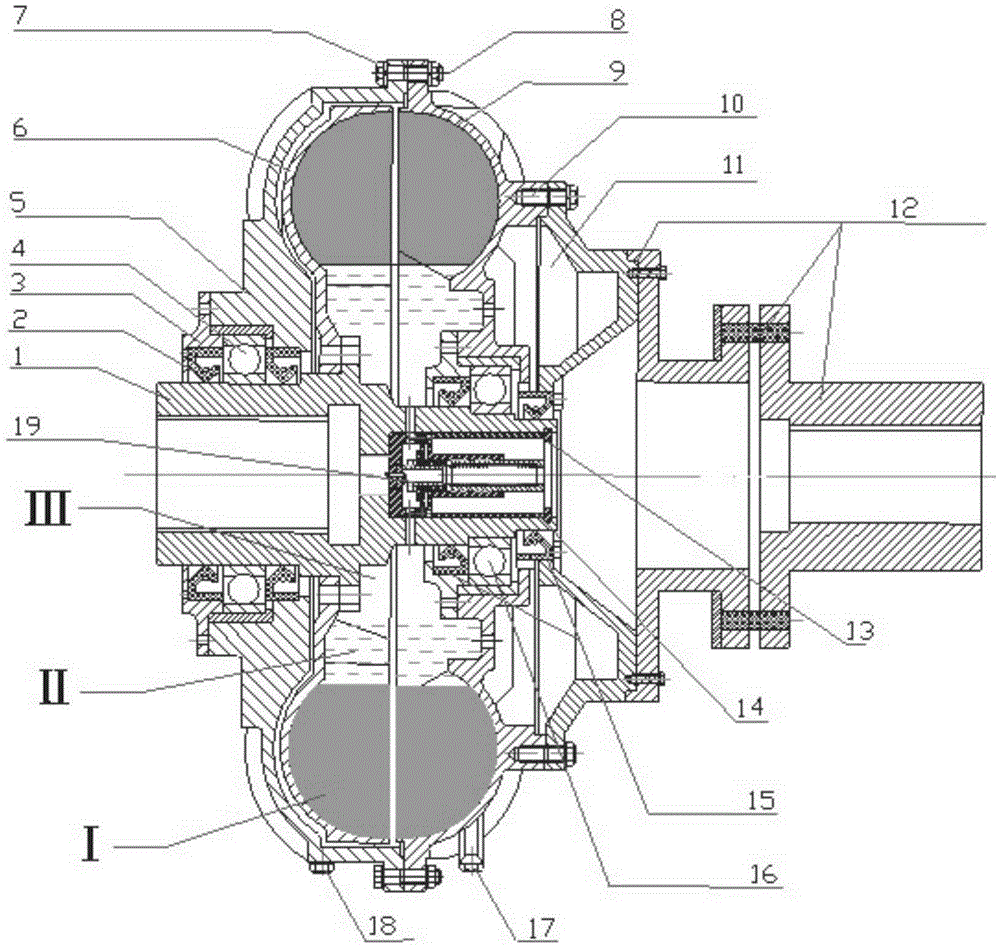

[0098] A water medium coupler, the water medium coupler sequentially includes: an input coupling assembly connected to a motor at an input end, a rotating casing for transmission, a turbine and a pump wheel arranged in the rotating casing for transmission, forming The ring-shaped airtight auxiliary chamber between the rotary housing and the input coupling assembly passes through the hollow turbine shaft at the input end and the output end. Water is used in the coupling cavity, that is, the space formed by the pump wheel and the rotary housing. medium. The input coupling part 12 consists of the input coupling and associated elastic connectors.

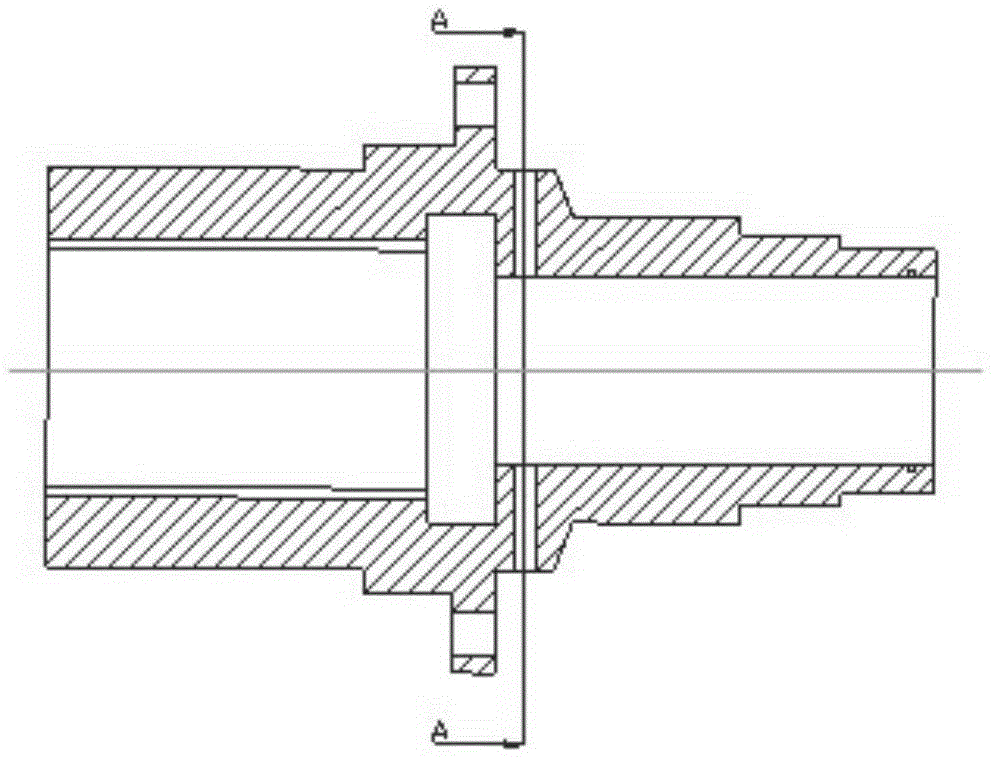

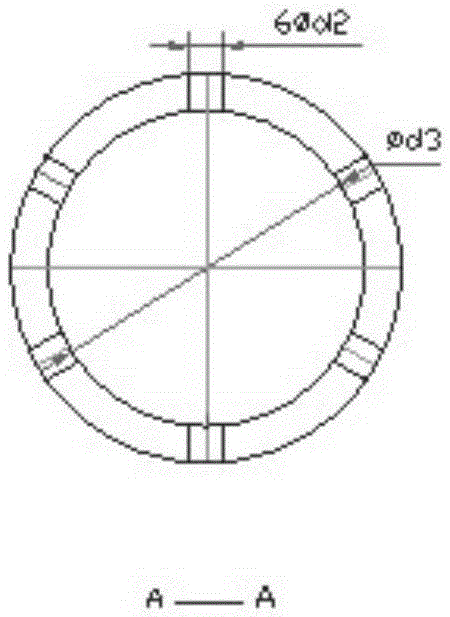

[0099] The turbine shaft 1 is hollow, and an internal relief valve 19 is built in the hollow part of the connection end of the turbine shaft 1 with the input coupling assembly. The auxiliary chamber 11 is a ring formed between the rotary housing 5 and the input coupling assembly 12. The root of the pump wheel 9 is provided with a throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com