Braking system testing equipment and method

A technology of braking system and testing method, which is applied in the direction of railway vehicle testing, etc., can solve problems such as comprehensive testing without the convenience of KE distribution valve performance, and achieve the effect of simple testing and guaranteed reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

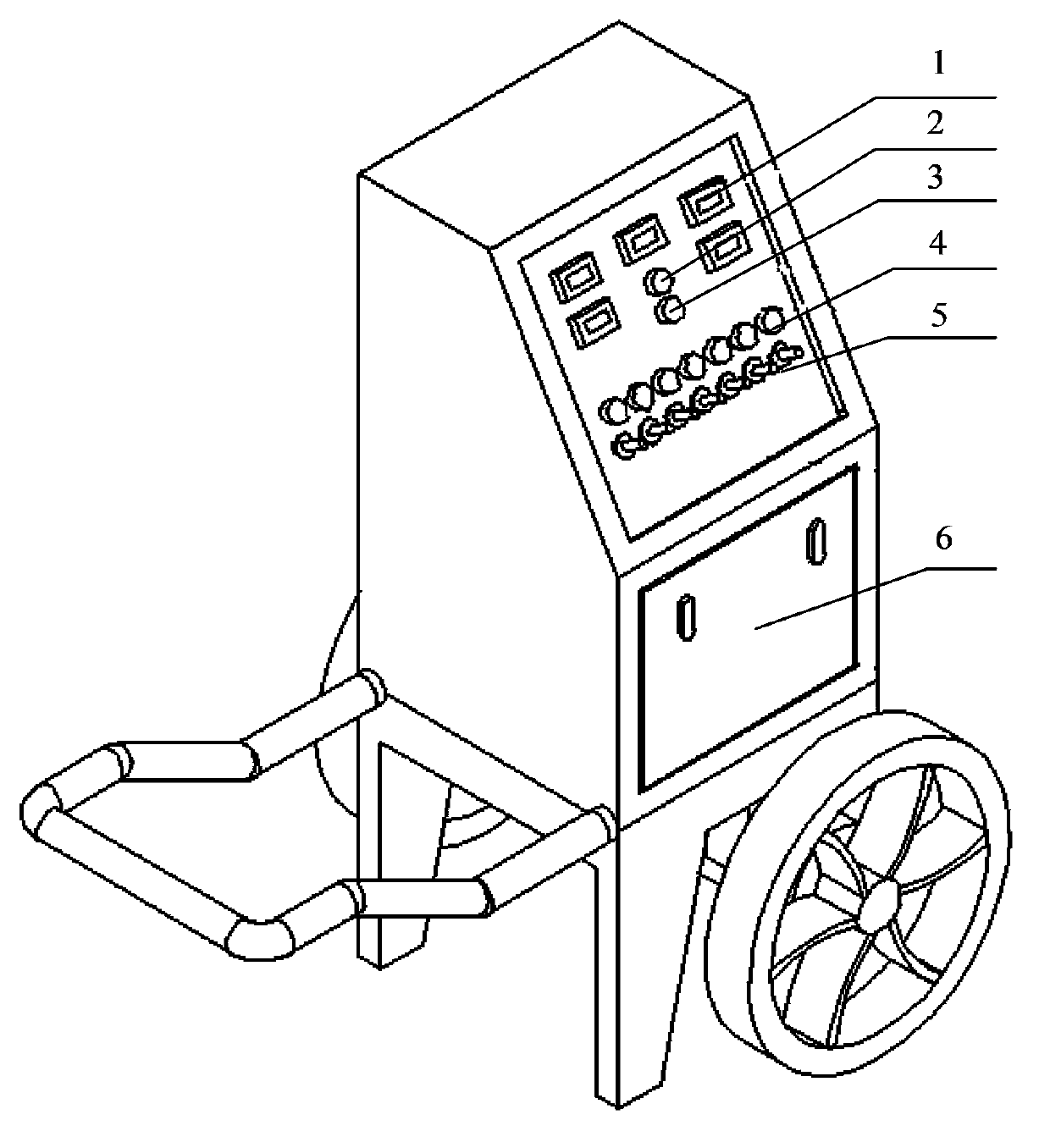

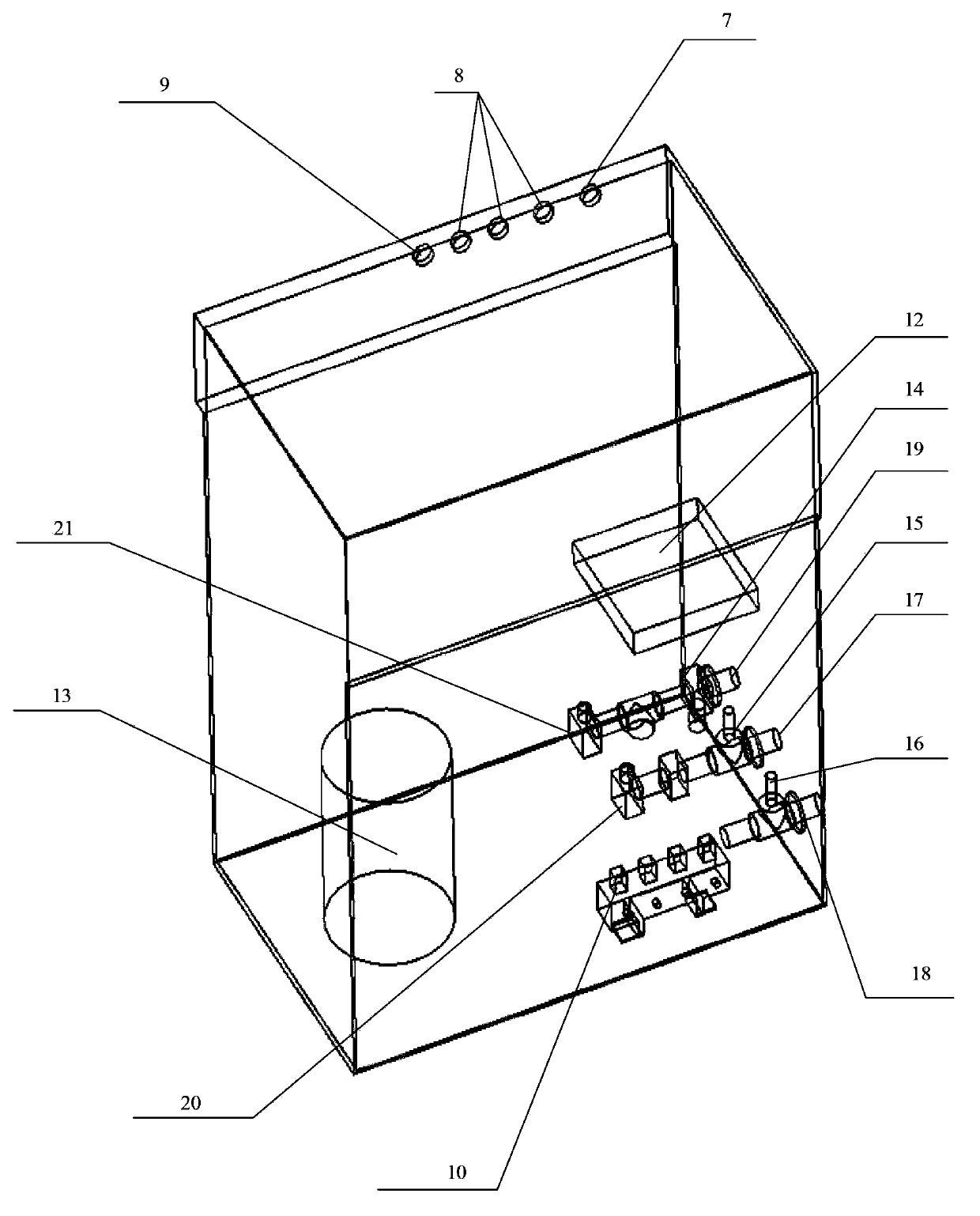

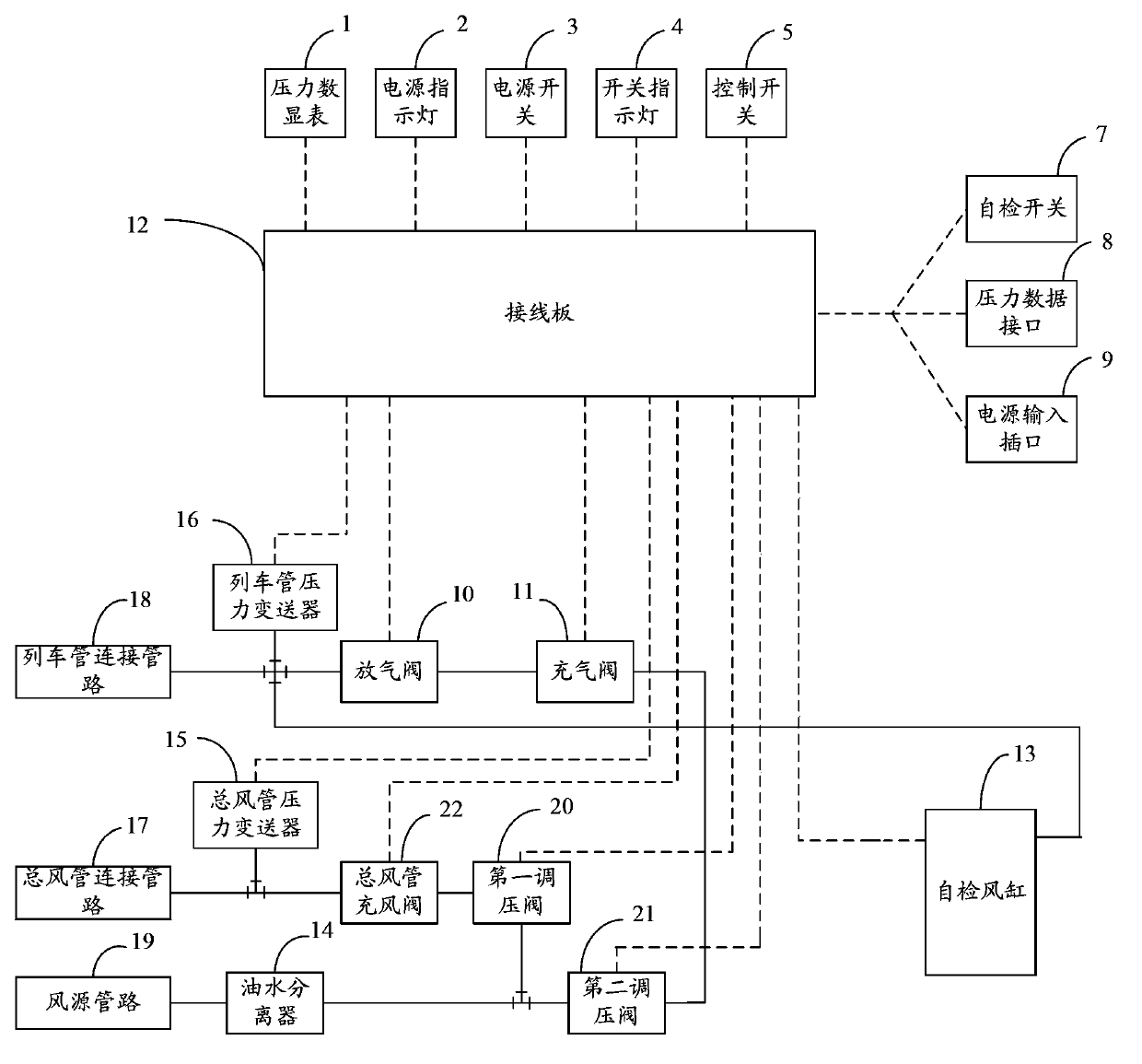

[0027] figure 1 An external structural diagram of the braking system testing equipment provided in Embodiment 1 of the present invention, figure 2 The internal structure diagram of the braking system testing equipment provided by Embodiment 1 of the present invention. image 3 It is a connection principle diagram of the braking system testing equipment provided by Embodiment 1 of the present invention.

[0028] Such as Figure 1-3 As shown, the brake system testing equipment includes: a main air pipe connecting pipeline 17, a train pipe connecting pipeline 18, an air source pipeline 19, an air cylinder pressure transmitter and a control module.

[0029] The interface of the main air duct connecting pipeline 17 is used to connect the main air duct of the vehicle to be tested, and the main air duct connecting pipeline 17 is equipped with a main air duct pressure transmitter 15 for collecting the pressure value in the main air duct; The interface of the train pipe connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com