Improved touch pen conducting means

A stylus and touch technology, applied in electrical digital data processing, data processing input/output process, instruments, etc., can solve the problems of touch panel inoperability, multi-surface processing cost, TouchPanel failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

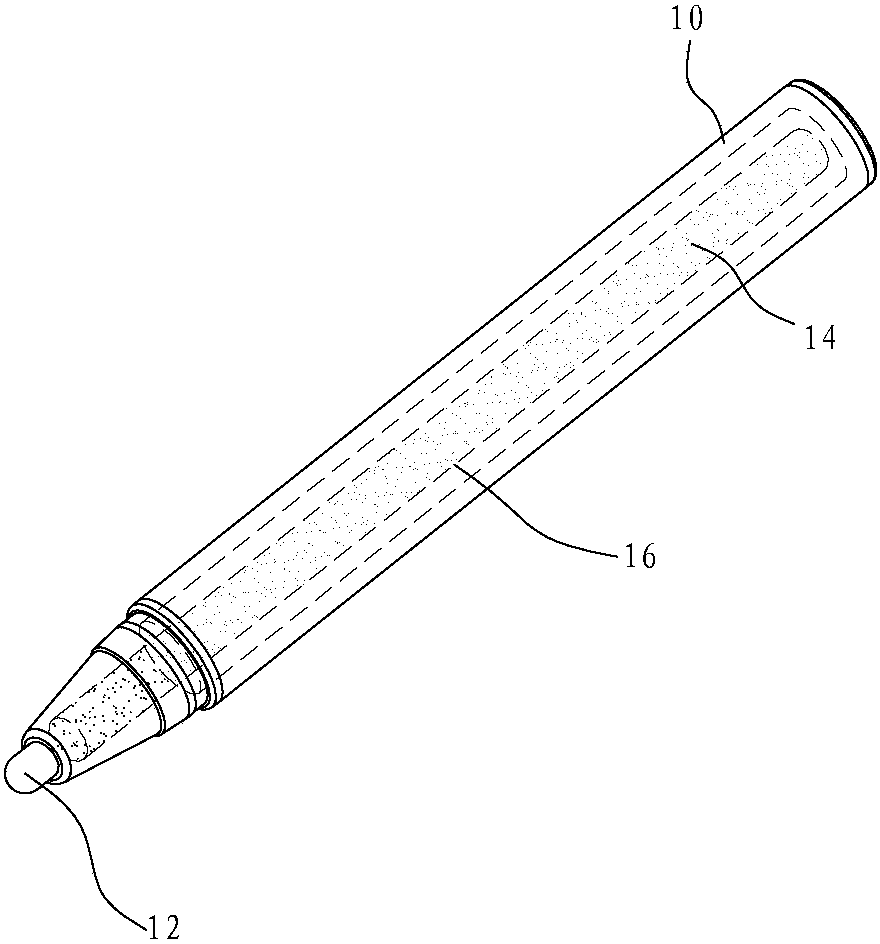

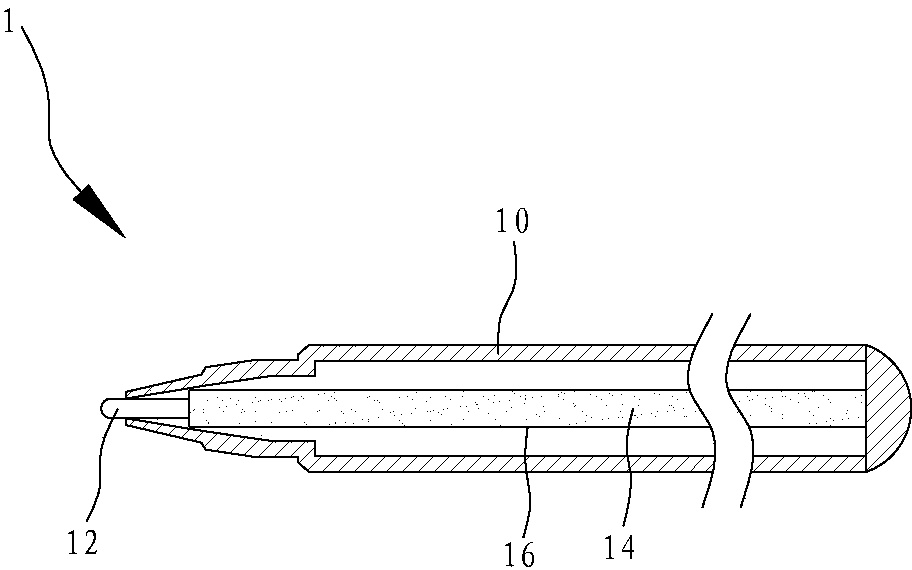

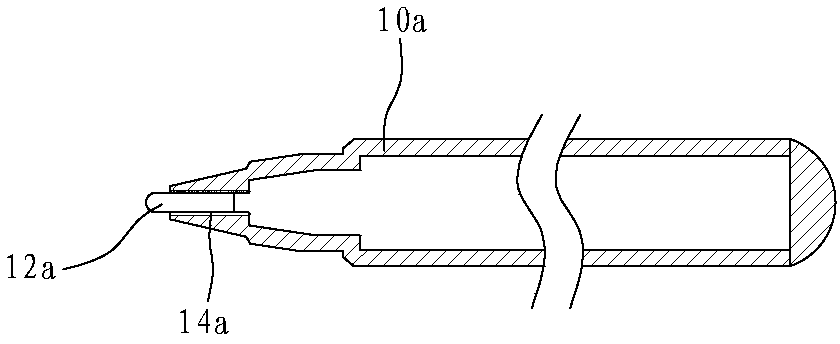

[0031] see figure 1 and figure 2 As shown, it is a three-dimensional schematic diagram and a schematic cross-sectional structure diagram of a preferred embodiment of the present invention. In order to achieve the aforementioned purpose, the present invention provides an improved stylus conduction method. The stylus 1 mainly consists of a non-conductive pen body 10 and a touch head 12, wherein a refill 16 (which can be a sponge, cloth or other absorbing body with good absorbability) is placed inside the non-conductive pen body 10 to absorb a conductive agent 14, and the refill 16 can be used for adsorption conductive agent 14, and the touch head 12 is in direct contact with the refill 16, therefore, the touch head 12 can detect the capacitance change on the surface of the panel through the refill 16 adsorbed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com