A polylactic acid colored long slub yarn and drawing device and processing method for processing thereof

A processing method and technology of polylactic acid, applied in the directions of yarn, spinning machine, textile and papermaking, etc., can solve the problems of easy hardening color fastness and high production cost of yarn, and achieve various styles, low processing cost, and yarn. Stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Step 1, raw material preparation, using the conventional dope coloring process to prepare 4 colors of polylactic acid colored staple fibers, namely white, red, yellow and black;

[0036] Step 2, clearing, respectively pass the polylactic acid colored short fibers of various colors through the cotton opening machine to make cotton laps of a certain size, and the dry basis weight of the cotton laps is 380 g / m;

[0037] Step 3, carding, carding the cotton rolls of various colors to make slivers of various colors, the dry weight of the carding sliver is controlled at 20 g / 5m;

[0038] Step 4, head drawing, the raw slivers of various colors are passed through the head and made into pre-drawing, and the dry weight of the pre-drawing is controlled at 19 g / 5m;

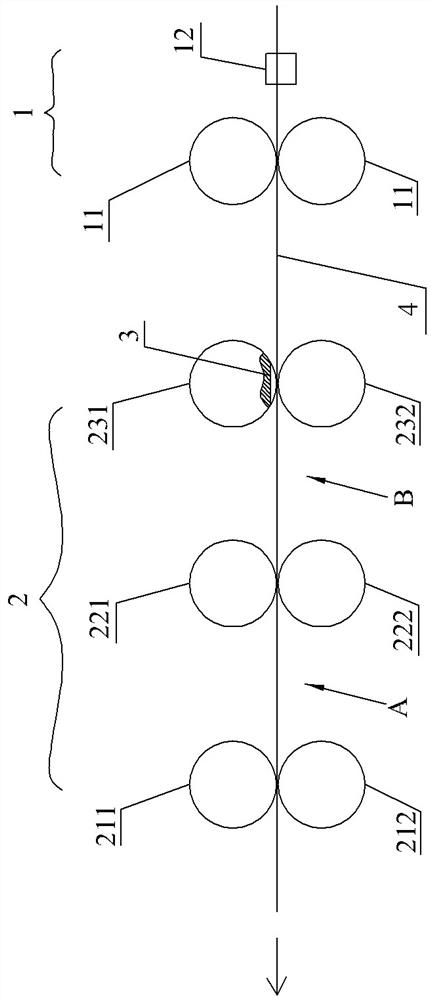

[0039] Step 5, final merging, press 2 pre-drawing bars red, 2 white, 2 black, and 2 yellow Figure 4 As shown, the slivers of different colors are fed into the cotton feeding roller 11 in parallel at the same time, and...

Embodiment 2

[0045] Step 1, raw material preparation, using the conventional dope coloring process to prepare polylactic acid colored staple fibers in three colors, namely red, blue, and pink, and then prepare white tencel fibers;

[0046] Step 2, cleaning, respectively pass the colored polylactic acid staple fibers and tencel fibers of various colors through the cleaning opener to make cotton laps of a certain size, and the dry basis weight of the cotton laps is 365 g / m;

[0047] Step 3, carding, carding the cotton laps of various colors to make slivers of various colors, the dry weight of the carding sliver is controlled at 19 g / 5m;

[0048] Step 4, head drawing, the raw slivers of various colors are passed through the head and made into pre-drawing, and the dry weight of the pre-drawing is controlled at 17.5g / 5m;

[0049] Step 5, final merging, press 2 pre-drawn bars red, 2 blue, 2 pink, and 2 white Figure 4 As shown, the slivers of different colors are fed into the cotton feeding rol...

Embodiment 3

[0055] Step 1, raw material preparation, using the conventional dope coloring process to prepare polylactic acid colored staple fibers of two colors, namely red and black, and then prepare white polyester fibers;

[0056] Step 2, cleaning, the fibers of various colors are respectively passed through the cleaning and opening machine to make cotton laps of a certain size, and the dry basis weight of the cotton laps is 380 g / m;

[0057] Step 3, carding, carding the cotton rolls of various colors to make slivers of various colors, the dry weight of the carding sliver is controlled at 20 g / 5m;

[0058] Step 4, head drawing, the raw slivers of various colors are passed through the head and made into pre-drawing, and the dry weight of the pre-drawing is controlled at 18.3g / 5m;

[0059] Step 5, final slitting, feed 2 red slivers, 2 black slivers, and 2 white slivers in parallel to the feeding roller at the same time, the slivers of different colors are separated by a slitter, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com