Anisotropic conductive film, composition for same, and semiconductor device

An anisotropic, conductive film technology, used in semiconductor devices, conductive adhesives, conductive materials dispersed in non-conductive inorganic materials, etc., can solve problems such as the operation of bonding failure equipment, the inability of bonding equipment to reach the bonding temperature, etc., Achieving the effect of low adhesion strength reduction rate, excellent adhesion and connection reliability, and low connection resistance growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 3

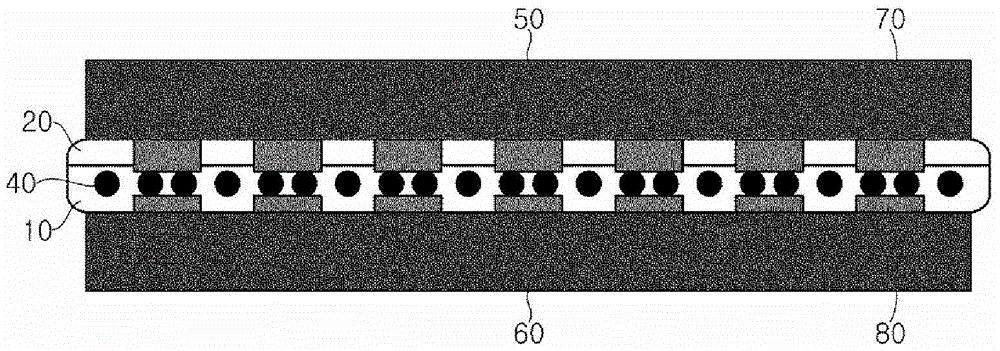

[0085] Examples 1 to 3: Preparation of anisotropic conductive composition and anisotropic conductive film

[0086] Acrylonitrile butadiene copolymer, acrylate-modified urethane resins 1 and 2, acryl-based copolymer, free radical polymerizable material 1 and 2, organic peroxide were blended in the amounts listed in Table 1. material, titanium dioxide, silicon dioxide, and conductive particles, and then stirred with a planetary mixer at 25° C. for 60 minutes while preventing the conductive particles from being pulverized. The resulting mixture was coated on a polyethylene-based film treated with a silicone release surface to form a film with a thickness of 35 μm. Each of the anisotropic conductive films of Examples 1 to 3 was prepared by forming a film using a casting blade and then drying at 60° C. for 5 minutes.

experiment example

[0103] Experimental example: Measurement of storage modulus at 40°C, initial adhesive strength, initial connection resistance, and connection resistance after reliability testing

[0104] The storage modulus at 40° C., initial adhesive strength, initial connection resistance, and connection resistance after the reliability test of the anisotropic conductive films prepared in Examples and Comparative Examples were measured as follows.

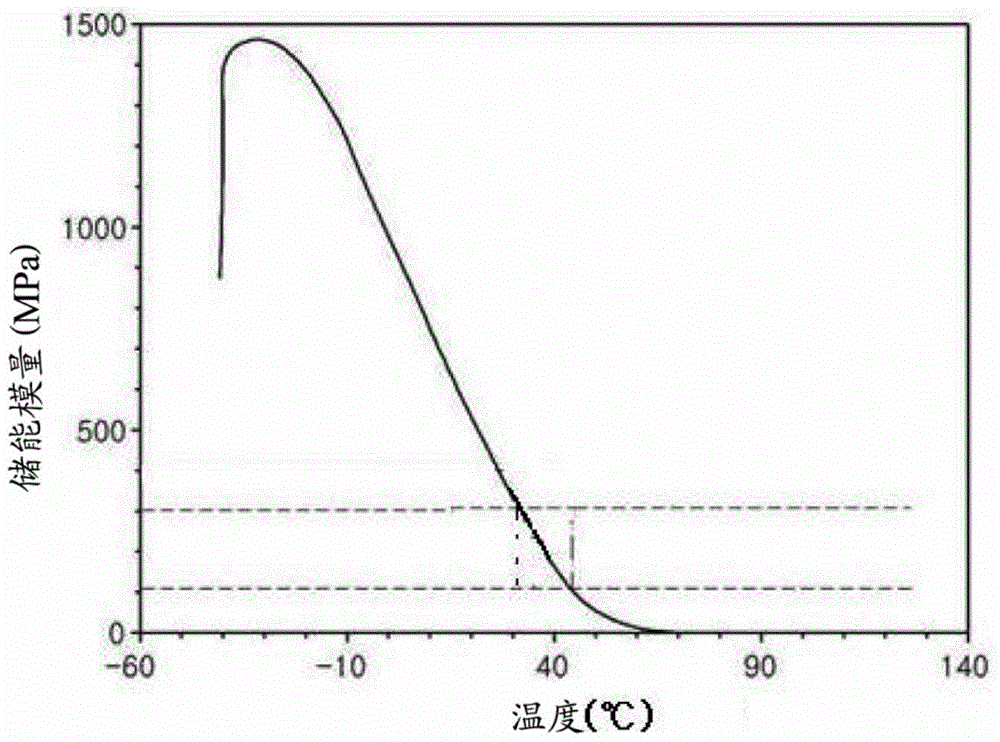

[0105] (1) Storage modulus at 40°C

[0106] A 35 μm thick anisotropic conductive film was placed on a heat press, and a 0.2 mm thick silicone rubber was placed on the film, and heated and compressed at 190 °C and 30 MPa for 15 minutes to cure the above connection material, and then the release Type film.

[0107] Then, the storage modulus of the film at 40° C. was measured using a dynamic mechanical analyzer (DMA) (TA Instruments) while heating from −40° C. to 200° C. at a rate of 10° C. / min.

[0108] (2) Initial adhesive strength and initial ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| storage modulus | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com