Injection molding sealing through-wall electric connector

An electrical connector and wall-penetrating technology, which is applied in the field of injection-molded sealed wall-penetrating electrical connectors, can solve problems such as poor sealing, softening and leakage of adhesive glue or sintered materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The injection-molded sealed through-wall electrical connector of the present invention will be further described in detail in conjunction with the drawings and embodiments below:

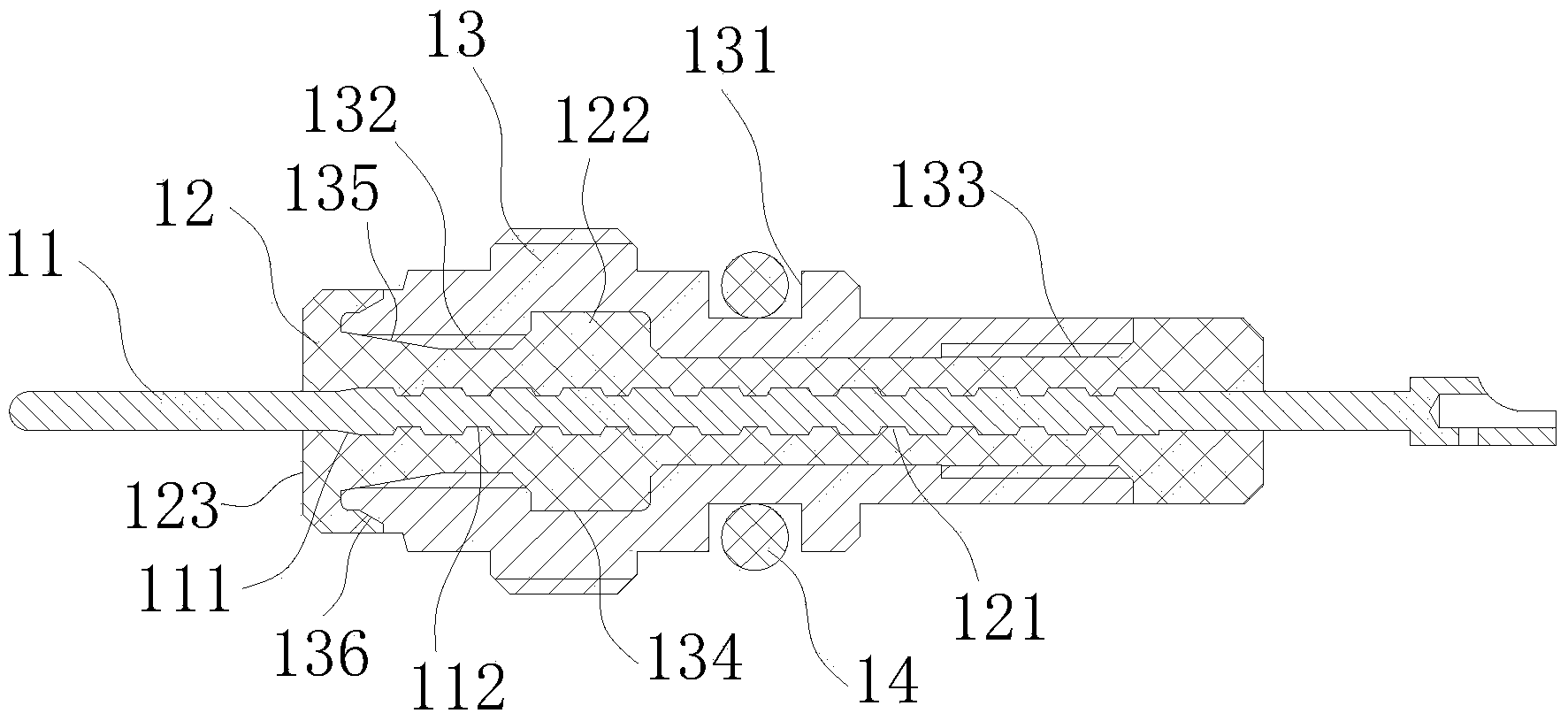

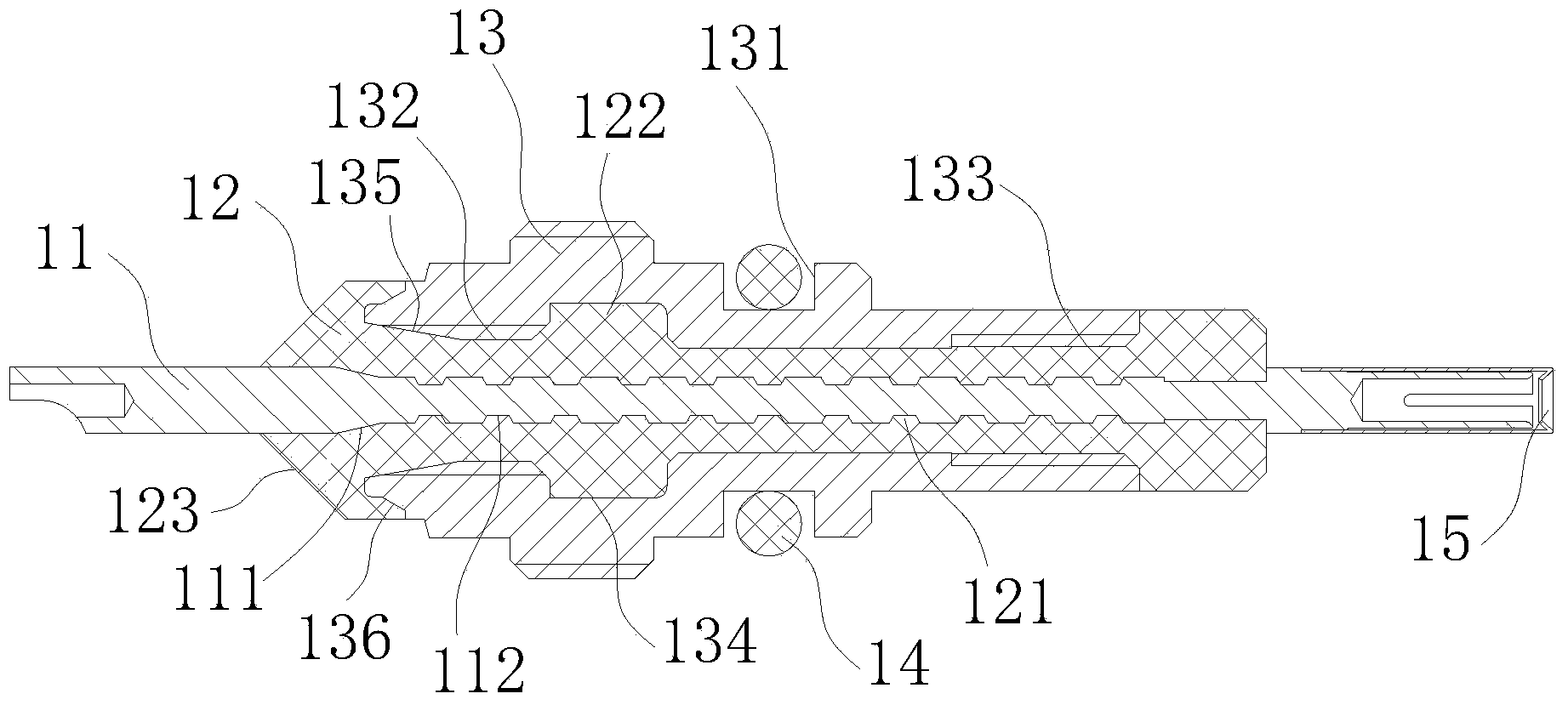

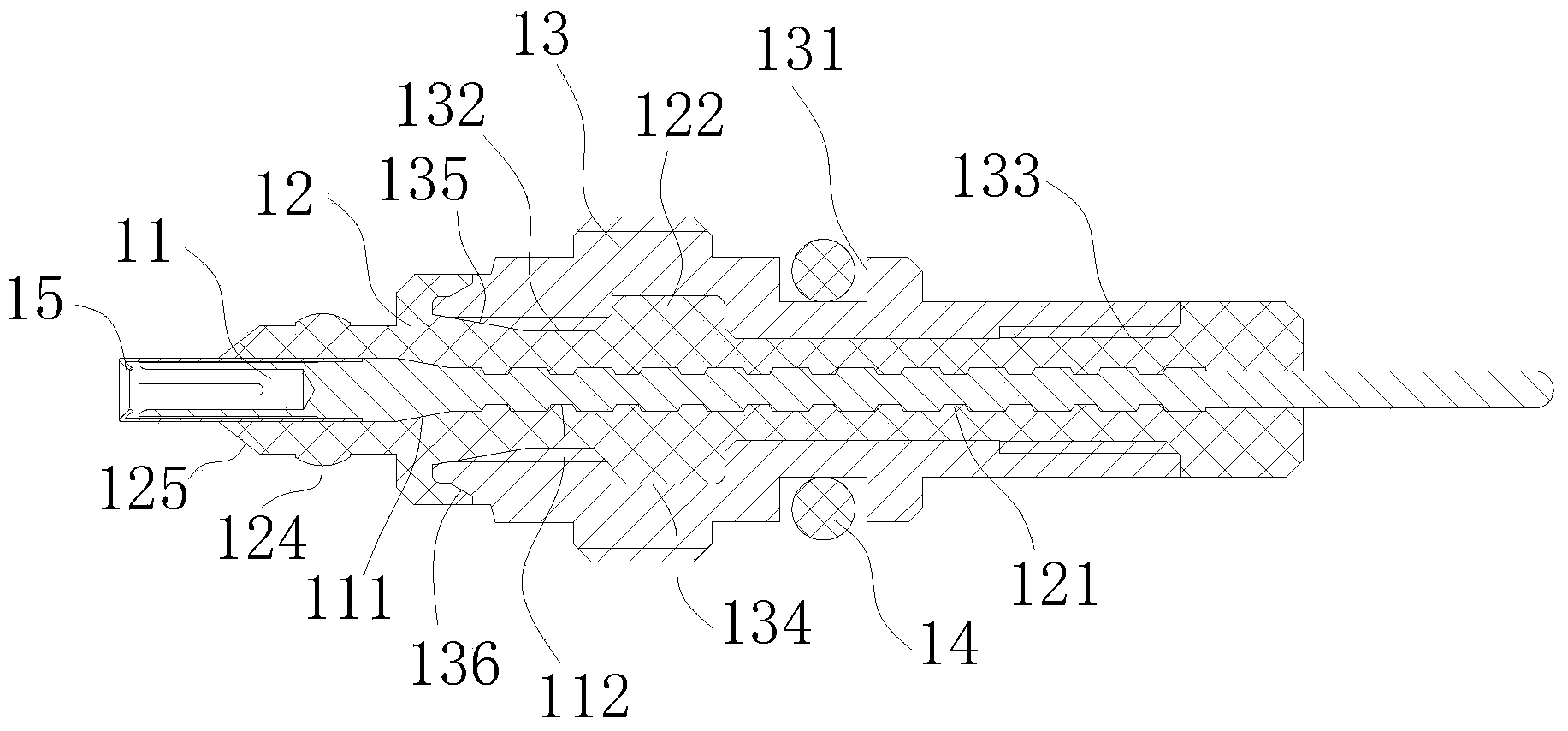

[0022] figure 1 Shown is a structural cross-sectional view of an embodiment of an injection-molded sealed through-wall electrical connector of the present invention. As shown in the figure, it includes a conductor contact 11 capable of transmitting current, surrounded by an injection molded insulator 12, and a metal shell 13 is arranged on the periphery of the above injection molded insulator 12, and a sealing ring 14 is arranged at the sealing groove 131 on it. . The inner seal is realized by the injection molding structure; the outer seal is realized by the compression deformation of the commonly used sealing ring 14, and the sealing ring 14 is made of elastic material, usually high temperature resistant fluororubber. The pressure-bearing end of the conductor contact 11 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com