A filter stick particle additive with coffee or cocoa flavor, its preparation method and application

A particle additive and filter rod technology, which is applied in applications, e-liquid filter elements, and fat generation, can solve problems such as difficult to meet industry needs and unstable coffee aroma, and achieve low production costs, rich taste and aroma experience, and less consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

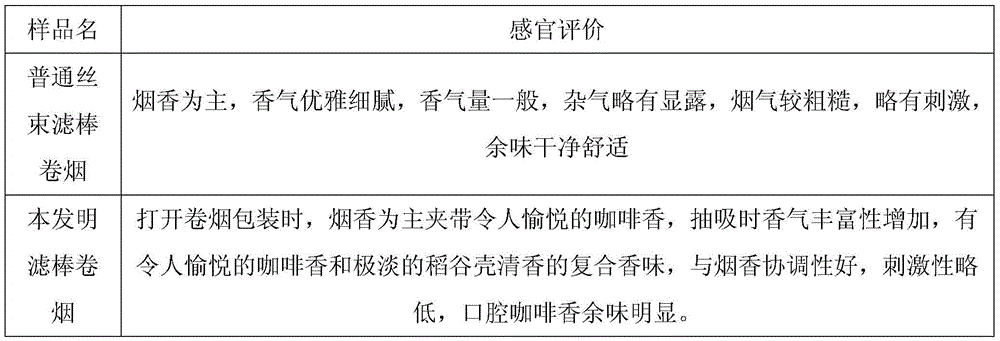

Embodiment 1

[0022] 1. Take dry rice husk powder, remove impurities, and after mechanical crushing, sieve to obtain granular materials with a particle size of 30-60 mesh;

[0023] 2. Take an appropriate amount of coffee powder and dissolve it in tap water to make a 1wt% aqueous solution;

[0024] 3. Take 1 part of the granules prepared in step 1 and 0.5 part of the aqueous solution prepared in step 2, spray the aqueous solution evenly on the granules, and let it stand for 0.5 hours;

[0025] 4. Move the wet material prepared in step 3 into a microwave vacuum drying oven for drying, and control the moisture content of the material to 6wt%-12wt%.

[0026] 5. The dried material obtained in step 4 is further sieved, and the particles with a particle size of 30-60 meshes are taken to obtain the required filter stick particle additive with coffee aroma.

[0027] The granular material is added to cigarette filter rods according to the addition amount of 1 mg / mm fiber base material to make rice h...

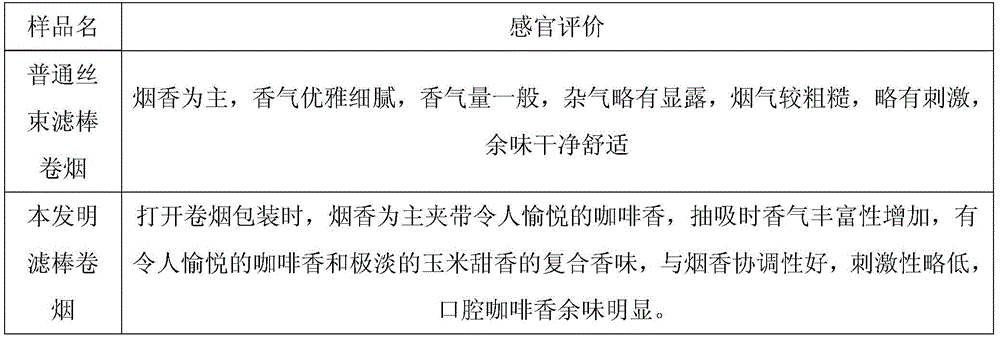

Embodiment 2

[0031] 1. Take dry corn cob powder, remove impurities, mechanically pulverize, and sieve to obtain granular materials with a particle size of 30-60 mesh;

[0032] 2. Take an appropriate amount of edible coffee essence and dissolve it in tap water to form a 0.5wt% aqueous solution;

[0033] 3. Take 1 part of the granule prepared in step 1 and 0.5 part of the aqueous solution prepared in step 2, spray the aqueous solution evenly on the granules, and let it stand for 2 hours;

[0034] 4. Move the wet material prepared in step 3 into a microwave vacuum drying oven for drying, and control the moisture content of the material to 6wt%-12wt%.

[0035] 5. The dried material obtained in step 4 is further sieved, and the particles with a particle size of 30-60 meshes are taken to obtain the required filter stick particle additive with coffee aroma.

[0036] The granular material is added to cigarette filter sticks according to the addition amount of 2 mg / mm fiber base material to make c...

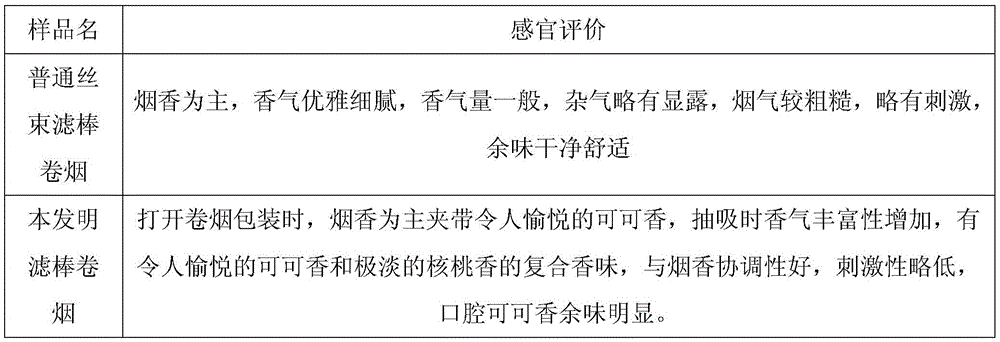

Embodiment 3

[0040] 1. Take dried walnut shell powder, remove impurities, mechanically pulverize, and sieve to obtain granular materials with a particle size of 30-60 mesh;

[0041] 2. Take an appropriate amount of cocoa powder and dissolve it in tap water to form a 15wt% aqueous solution;

[0042] 3. Take 1 part of the granules prepared in step 1 and 0.5 part of the aqueous solution prepared in step 2, spray the aqueous solution evenly on the granules, and let it stand for 0.5 hours;

[0043] 4. Move the wet material prepared in step 3 into a microwave vacuum drying oven for drying, and control the moisture content of the material to 12%.

[0044] 5. The dried material obtained in step 4 is further sieved, and the particles with a particle size of 30-60 meshes are taken to obtain the required filter stick particle additive with cocoa flavor.

[0045] The granular material is added to the cigarette filter rod according to the addition amount of 1.5 mg / mm fiber base material to make a waln...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com