Negative ion functional material as well as preparation method and application thereof

A technology of functional materials and negative ions, which is applied in the field of negative ion functional materials and their preparation, can solve the problems of large differences in the amount of negative ions released, difficult mining, and small output, and achieves excellent negative ion release performance, simple preparation process, and safe raw materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

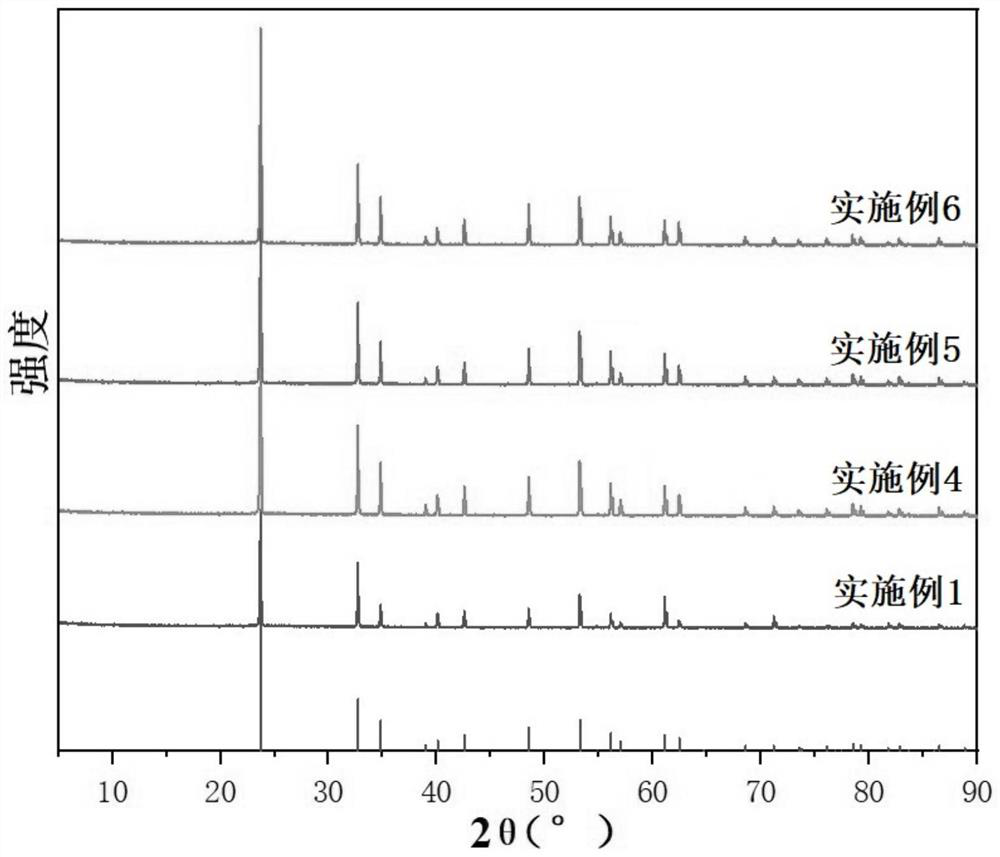

Image

Examples

Embodiment 1

[0035] A preparation method of negative ion functional material comprises the following steps:

[0036] 1) The Nb 2 O 5 and Li 2 CO 3 Add the ball mill in a molar ratio of 1:1, then add zirconia balls (composed of zirconia balls with particle sizes of 6mm, 4mm, 2mm and 1mm according to a mass ratio of 3:3:2:2) and deionized water. (Nb 2 O 5 and Li 2 CO 3 ), zirconia ball milling beads and deionized water are added in a ratio of 1g:1.5g:0.625mL, adjust the speed of the ball mill to 400r / min, ball mill for 5h, and then put the slurry obtained by ball milling into the blast drying oven , dried at 80°C for 24h, passed through a 100-mesh sieve, then placed in an electric furnace, heated to 760°C at a heating rate of 5°C / min, held for 4 hours, then heated to 1100°C at a heating rate of 5°C / min, held for 2h, Pass through a 100-mesh sieve to obtain lithium niobate;

[0037] 2) Lithium niobate and 5% mass fraction of polyvinyl alcohol (1788 type polyvinyl alcohol, degree of po...

Embodiment 2

[0039] A preparation method of negative ion functional material comprises the following steps:

[0040] 1) The Nb 2 O 5 and Li 2 CO 3 Add the ball mill in a molar ratio of 1:1, then add zirconia balls (composed of zirconia balls with particle sizes of 6mm, 4mm, 2mm and 1mm according to a mass ratio of 3:3:2:2) and deionized water. (Nb 2 O 5 and Li 2 CO 3 ), zirconia ball milling beads and deionized water are added in a ratio of 1g:1.5g:0.625mL, adjust the speed of the ball mill to 400r / min, ball mill for 5h, and then put the slurry obtained by ball milling into the blast drying oven , dried at 80°C for 24h, passed through a 100-mesh sieve, then placed in an electric furnace, heated to 760°C at a heating rate of 5°C / min, held for 4 hours, then heated to 1100°C at a heating rate of 5°C / min, held for 2h, Pass through a 100-mesh sieve to obtain lithium niobate;

[0041] 2) Lithium niobate and a polyvinyl alcohol (1788 type polyvinyl alcohol, degree of polymerization about...

Embodiment 3

[0043] A preparation method of negative ion functional material comprises the following steps:

[0044] 1) The Nb 2 O 5 and Li 2 CO 3 Add the ball mill in a molar ratio of 1:1, then add zirconia balls (composed of zirconia balls with particle sizes of 6mm, 4mm, 2mm and 1mm according to a mass ratio of 3:3:2:2) and deionized water. (Nb 2 O 5 and Li 2 CO 3), zirconia ball milling beads and deionized water are added in a ratio of 1g:1.5g:0.625mL, adjust the speed of the ball mill to 400r / min, ball mill for 5h, and then put the slurry obtained by ball milling into the blast drying oven , dried at 80°C for 24h, passed through a 100-mesh sieve, then placed in an electric furnace, heated to 760°C at a heating rate of 5°C / min, held for 4 hours, then heated to 1100°C at a heating rate of 5°C / min, held for 2h, Pass through a 100-mesh sieve to obtain lithium niobate;

[0045] 2) Lithium niobate and a polyvinyl alcohol (1788 type polyvinyl alcohol, degree of polymerization about ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com