Girald Daphne Bark total coumarin hydrogel matrix sustained release tablet

A total coumarin and hydrogel technology, which is applied in the field of Zushima total coumarin hydrogel matrix sustained-release tablets, can solve the problems of limited application of Zushima and its extract, short action time, etc. The frequency of taking the medicine, the long-lasting effect, and the effect of improving the curative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

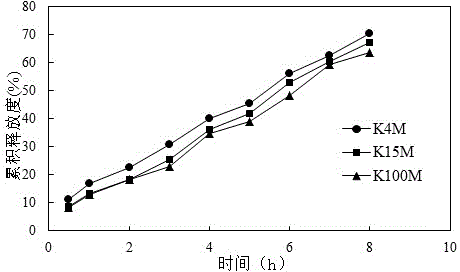

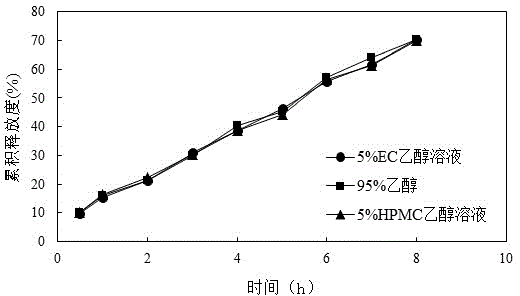

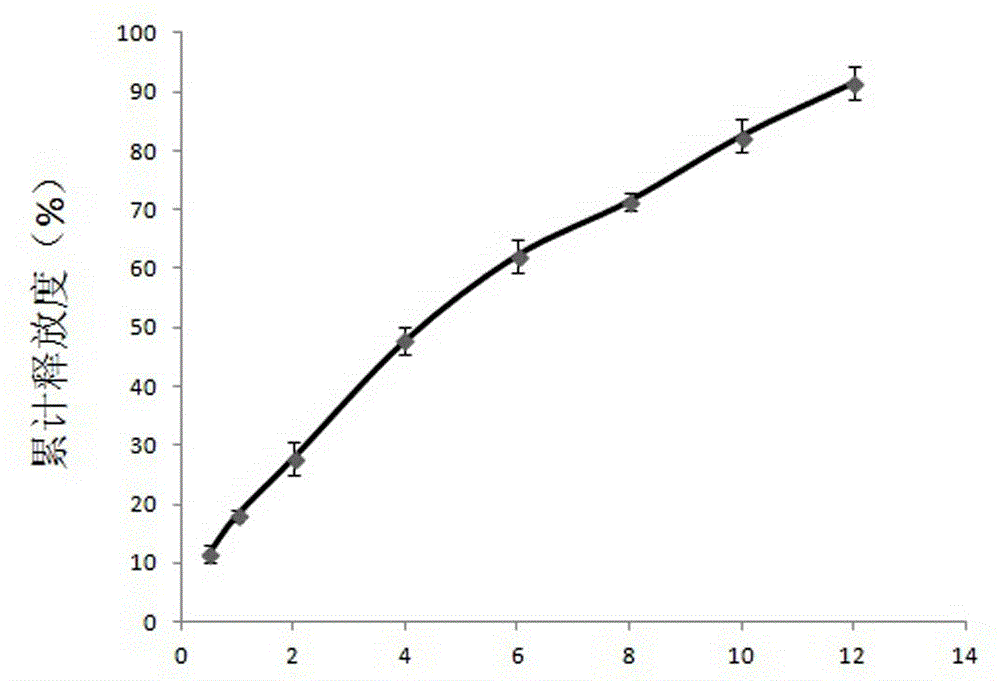

Method used

Image

Examples

Embodiment 1

[0029] A kind of Zushima total coumarin hydrogel skeleton sustained-release tablet, calculated by mass percentage, by mixing the following raw material components: Zushima total coumarin 35%, skeleton material 45%, filler 15% (by Microcrystalline cellulose and lactose in a weight ratio of 1:1), binder 2%, lubricant (talc) 3%.

[0030] When preparing, weigh the total coumarin, skeleton material and filler of Zushima, pass through a 100-mesh sieve and mix evenly, add a binder to make a soft material, granulate with a 20-mesh sieve, dry at 60°C for 2 hours, and sieve with a 18-mesh sieve. Granules, add lubricant, mix well, press tablet (pressure is 4, 7, 9kg / cm 2 ) to obtain Zushi Ma total coumarin hydrogel matrix sustained-release tablets.

Embodiment 2

[0032] A kind of Zushi Ma total coumarin hydrogel skeleton sustained-release tablet, calculated by mass percentage, by mixing the following raw material components: Zushi Ma total coumarin 55%, skeleton material 15%, filler 25% (by Microcrystalline cellulose and lactose in a weight ratio of 1:1), binder 4%, lubricant (micropowder silica gel) 1%.

[0033] The preparation method is the same as in Example 1.

Embodiment 3

[0035] A kind of Zushima total coumarin hydrogel skeleton sustained-release tablet, calculated by mass percentage, by mixing the following raw material components: Zushima total coumarin 45%, skeleton material 30%, filler 20% (by Microcrystalline cellulose and lactose in a weight ratio of 1:1), binder 3%, lubricant (magnesium stearate) 2%.

[0036] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com