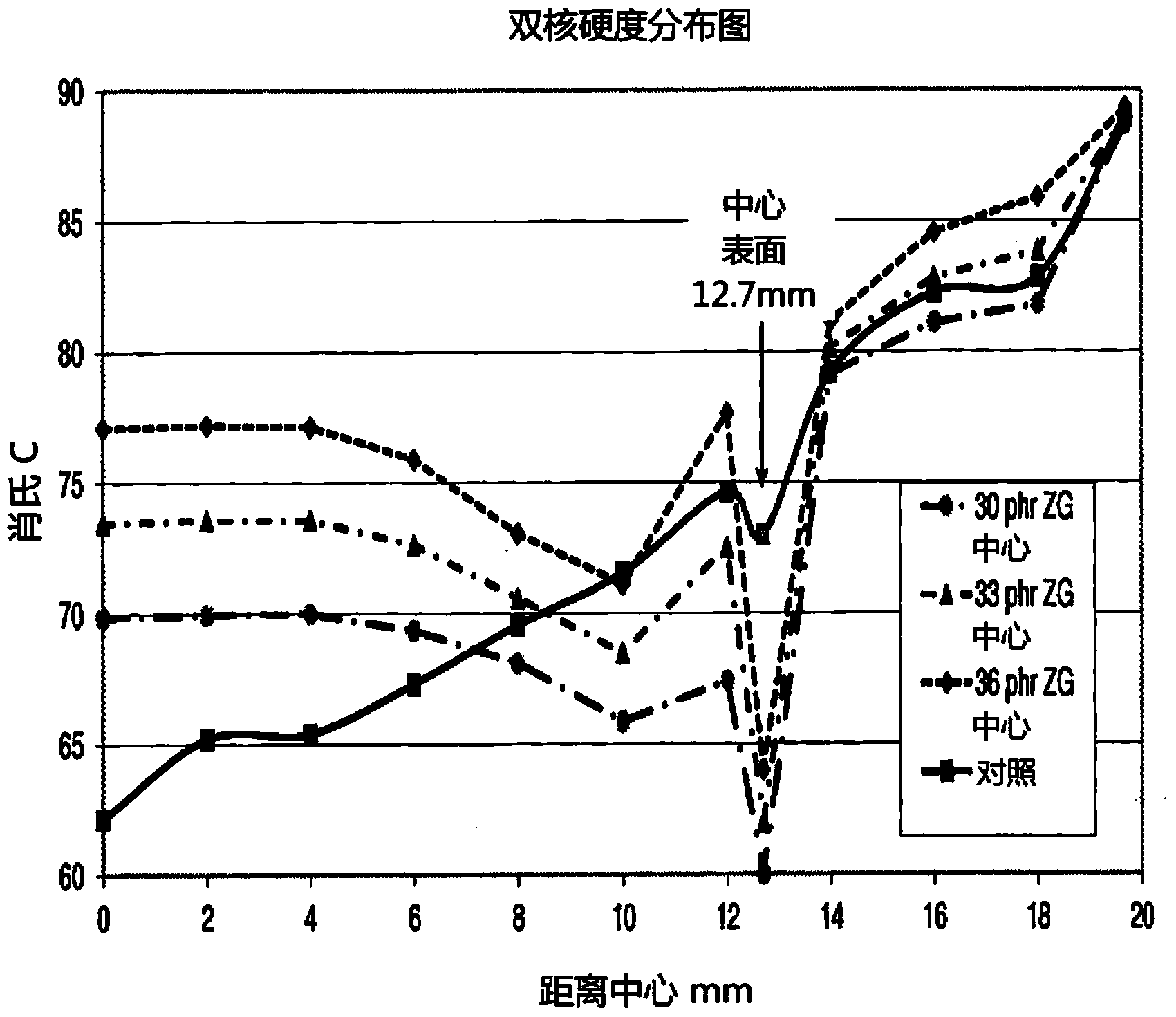

Dual-Core Comprising Zero Gradient Center And Positive Gradient Outer Core Layer

An outer core layer, geometric center technology, applied in the golf field, can solve the problem of time-consuming and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

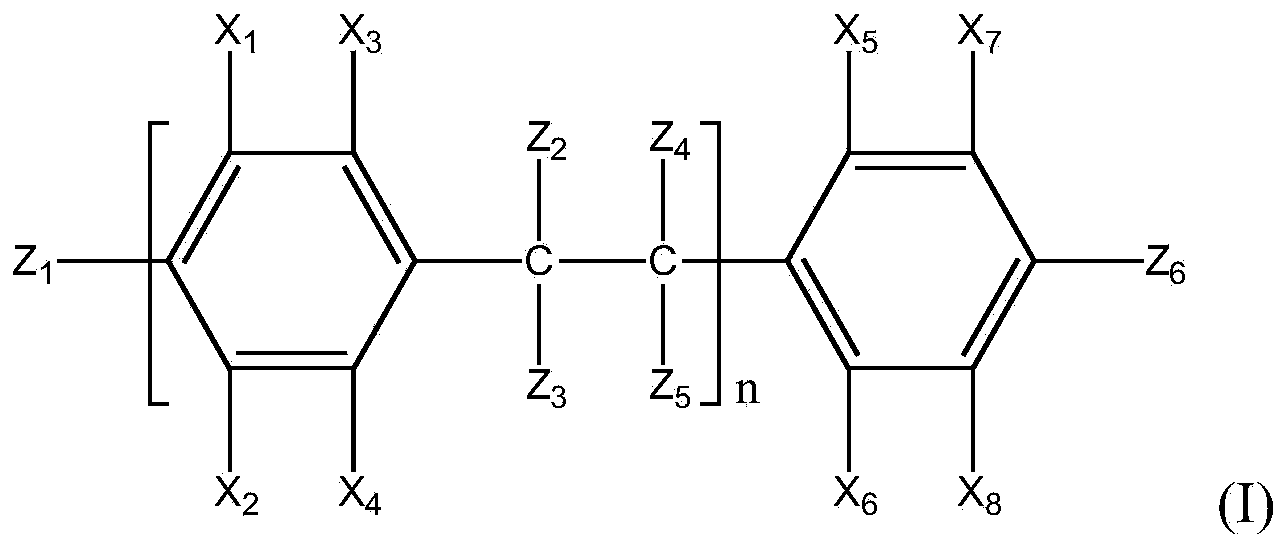

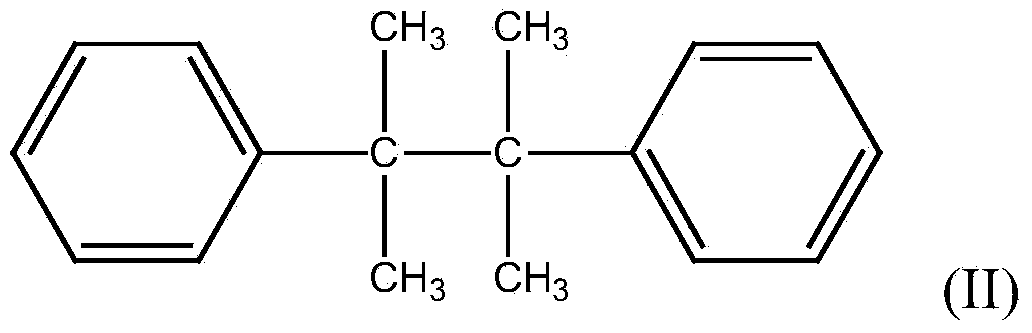

[0038] The term "carbon-carbon radical initiator" or "-C initiator" as used herein refers to the thermal decomposition of one or more extended carbon-carbon single bonds into free radicals by breaking and thus weakening them free radical initiators. These C-C initiators and their subgroups are also known, including compounds such as C-C unstable compounds, organic compounds with unstable or unstable C-C bonds, pure hydrocarbon initiators, aromatic hydrocarbons, Highly branched alkanes, sterically-crowded (sterically-crowded) phenyl substituted alkanes, dibenzyl or diphenyl curing catalysts, dicumyl compounds or synergists, alkyl substituted diphenyl compounds, Substituted succinates, diphenylethane derivatives, pinacols or pinacolones and their derivatives, silylbenzopinacols and their derivatives, non-peroxide radical initiators, free-radical A group donor or activator, a carbon-based donor, a carbon-based activator, a carbon-based accelerator, or a carbon-based product.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com