Ammonia exhaust gas treatment device

A technology for exhaust gas treatment and ammonia gas, which is applied in the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles. The effect of environmental protection control, economical filling and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

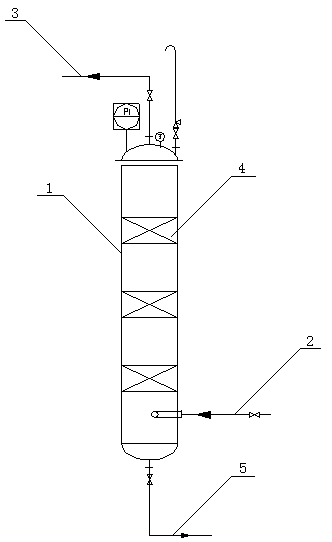

[0010] Such as figure 1 A kind of ammonia tail gas processing device shown, comprises filter 1, and filter 1 is respectively provided with ammonia gas inlet 2 and ammonia gas outlet 3, and filter 1 is distributed with 3 filter nets 4, and filter net 4 is divided into 3 layers, the thickness of each layer is 20 centimeters, the mesh number of the filter screen 4 is 25 mesh, and the bottom of the filter 1 is also provided with a liquid return outlet 5.

[0011] The treatment process of the present invention is as follows: the ammonia tail gas enters through the ammonia gas inlet, is filtered by the filter, and is discharged through the ammonia gas outlet, and at the same time, the return liquid can be discharged through the return liquid outlet for reuse.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com