Rejuvenating agent for hydrogen peroxide prepared by anthraquinone method and preparation method thereof

A technology of hydrogen peroxide and regenerant, applied in chemical instruments and methods, catalysts for physical/chemical processes, peroxides/peroxyhydrates/peroxyacids/superoxides/ozone oxides, etc. Problems such as difficult control of conditions, to achieve the effects of excellent physical and chemical properties, reasonable and scientific preparation methods, and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

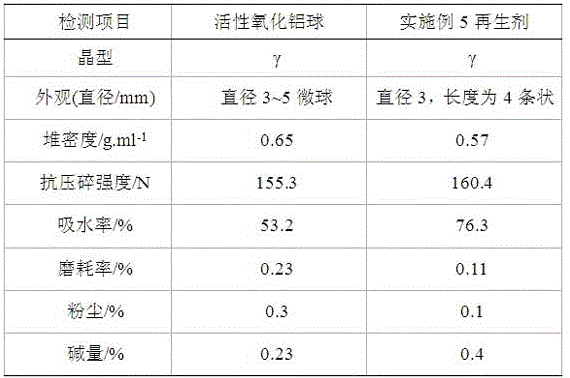

Embodiment 1

[0029] Alumina powder 950g Tianjing powder 50g

[0030] (1) After the de-alumina powder is mixed with the safflower powder, add 50g of an aqueous solution of nitric acid with a concentration of 10% by volume, mix evenly, and make strips;

[0031] (2) After drying in the shade at room temperature, roast at 600K for 3 hours to obtain a strip carrier;

[0032] (3) Immerse the strip-shaped carrier in 1L of 0.8mol / L sodium hydroxide solution for 1 minute, take it out, and dry it at 350K for 3 hours to obtain it.

Embodiment 2

[0034] Alumina powder 800g Sesame powder 200g

[0035] (1) After mixing alumina powder and sage powder, add 100g of nitric acid aqueous solution with a concentration of 20% by volume, mix evenly, and make strips;

[0036] (2) After drying in the shade at room temperature, roast at 700K for 3.5 hours to obtain a strip carrier;

[0037] (3) Soak 800ml of 2mol / L sodium hydroxide solution on the strip carrier, and dry it at 370K for 3.5h to obtain the product.

Embodiment 3

[0039] Alumina powder 900g Sesame powder 100g

[0040] (1) After mixing the alumina powder and the celadon powder, add 80g of glacial acetic acid aqueous solution with a concentration of 40% by volume, mix evenly, and make strips;

[0041] (2) After drying in the shade at room temperature, roast at 780K for 4 hours to obtain a strip carrier;

[0042] (3) Immerse the strip-shaped carrier in 600ml of 3mol / L sodium hydroxide solution for 10 seconds, take it out, and dry it at 380K for 4 hours to obtain it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com