Three-position automatic barrel changing device

A three-station, automatic technology, used in transportation and packaging, transportation of filamentous materials, thin material processing, etc., can solve the problems of low work efficiency, high labor intensity and high labor cost, achieve simple structure and reduce labor intensity. , the effect of stable running trajectory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

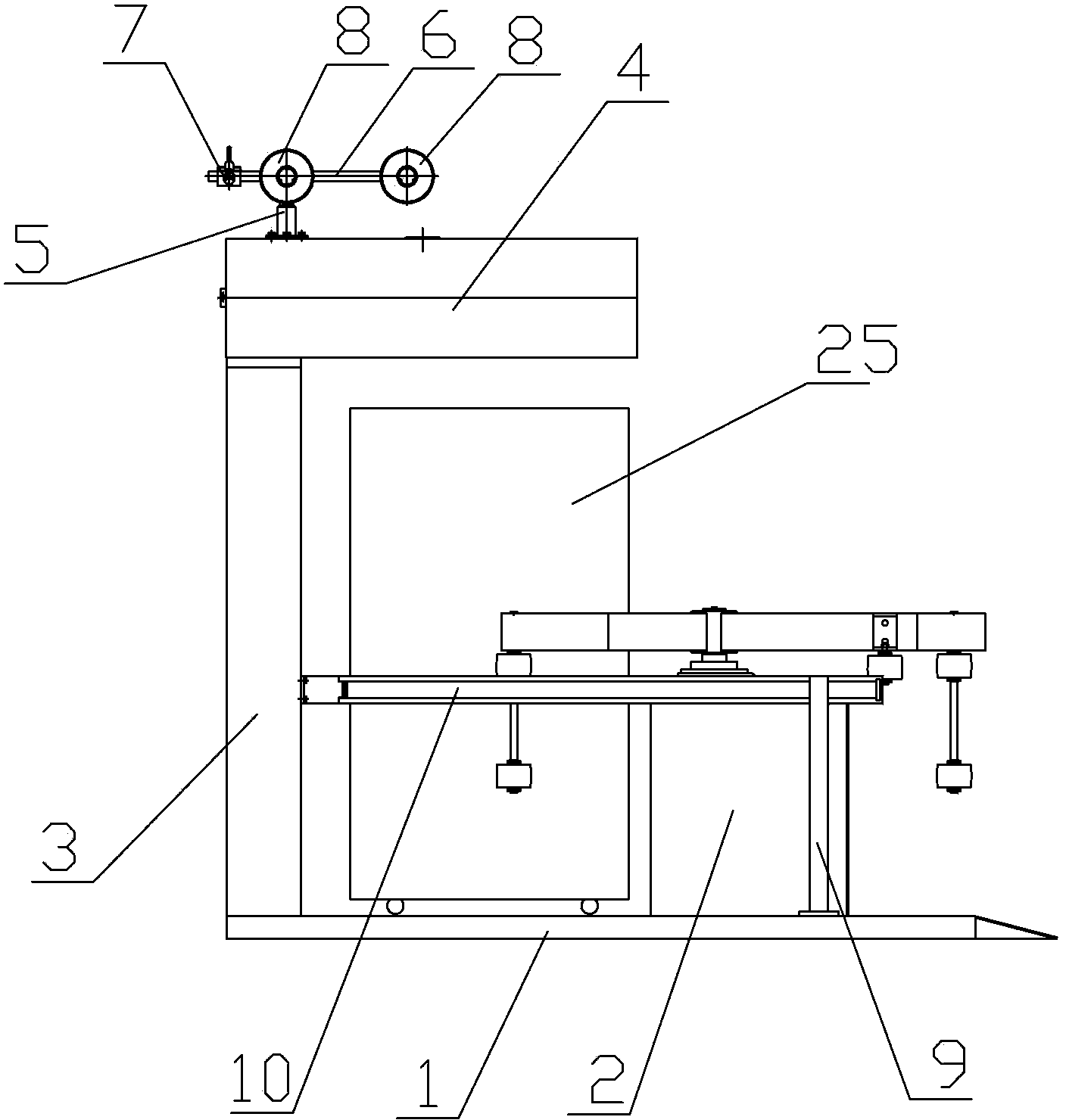

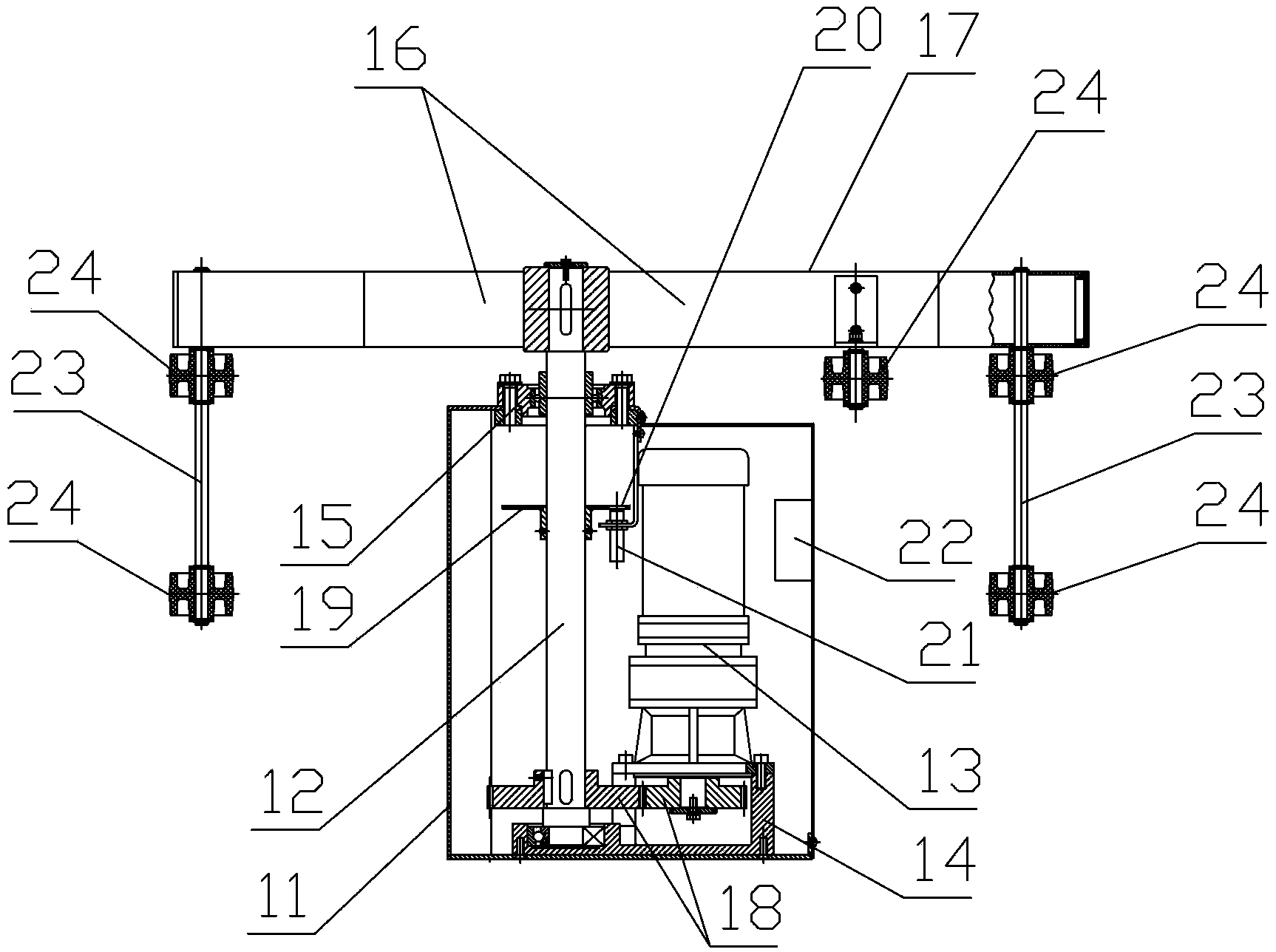

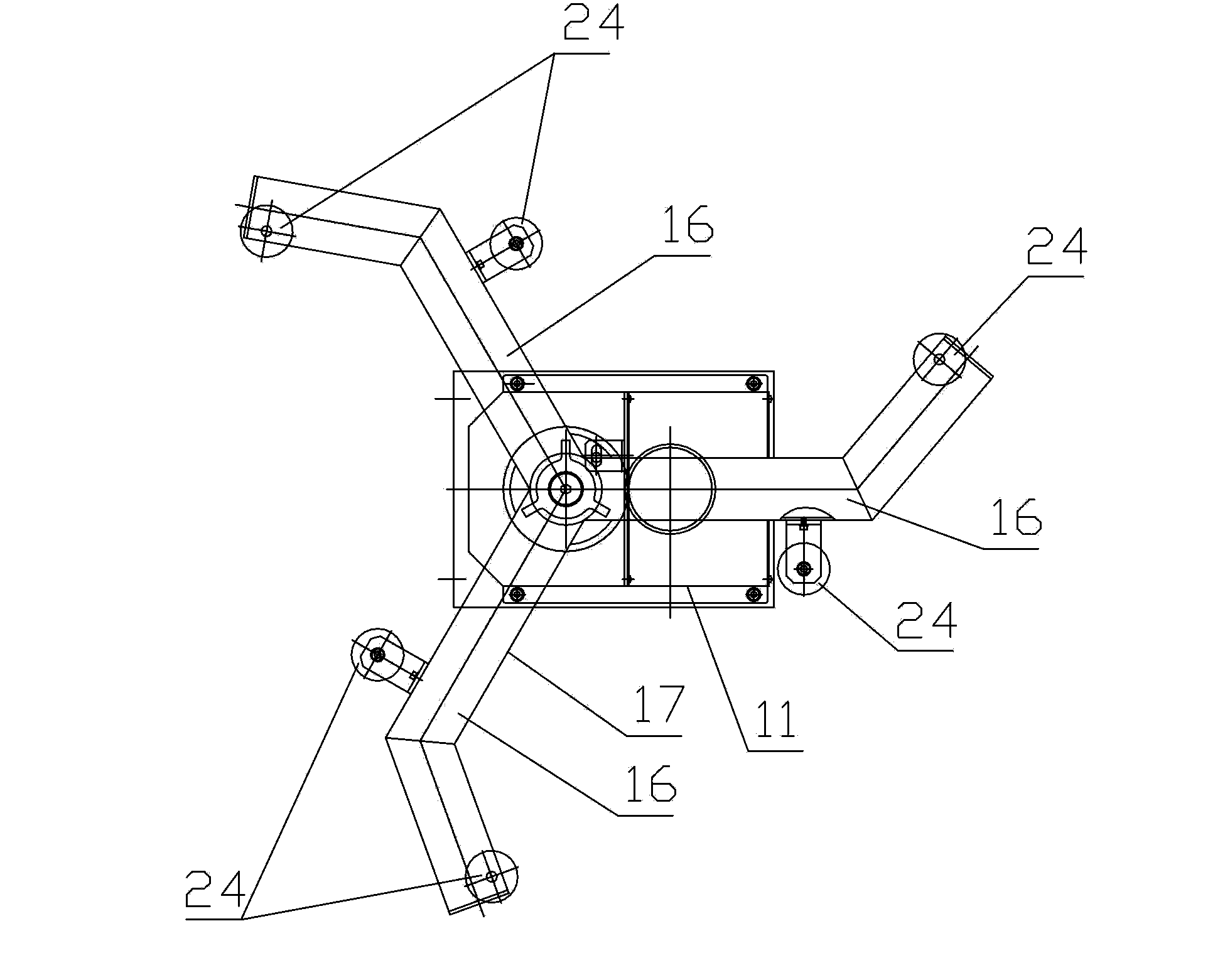

[0012] The three-station automatic barrel changing device of the present invention, such as figure 1 As shown, it includes a base 1, a rotary barrel changing device 2 installed on the base 1, a support column 3 is installed vertically on the rear of the base 1, a coiler 4 is installed on the top of the support column 3, and the upper surface of the coiler 4 is The rear part is equipped with an auxiliary support column 5, and a cross bar 6 is installed horizontally on the top of the auxiliary support column 5. A length measurement sensor 7 and a guide roller 8 are installed on the cross bar 6. Two brackets 9 are symmetrically installed on both sides of the front part of the base 1. , a U-shaped guardrail 10 with an opening forward is installed between the two brackets 9, the rear end of the U-shaped guardrail 10 is connected with the support column 3, the rotary drum changing device 2 is installed inside the U-shaped guardrail 10, and the length measuring sensor 7 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com