Oil field wastewater treatment process

A technology of oilfield sewage and treatment process, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, mining wastewater treatment, etc., can solve the problem of low treatment efficiency, achieve improved treatment efficiency, effective degradation, good The effect of degradation function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

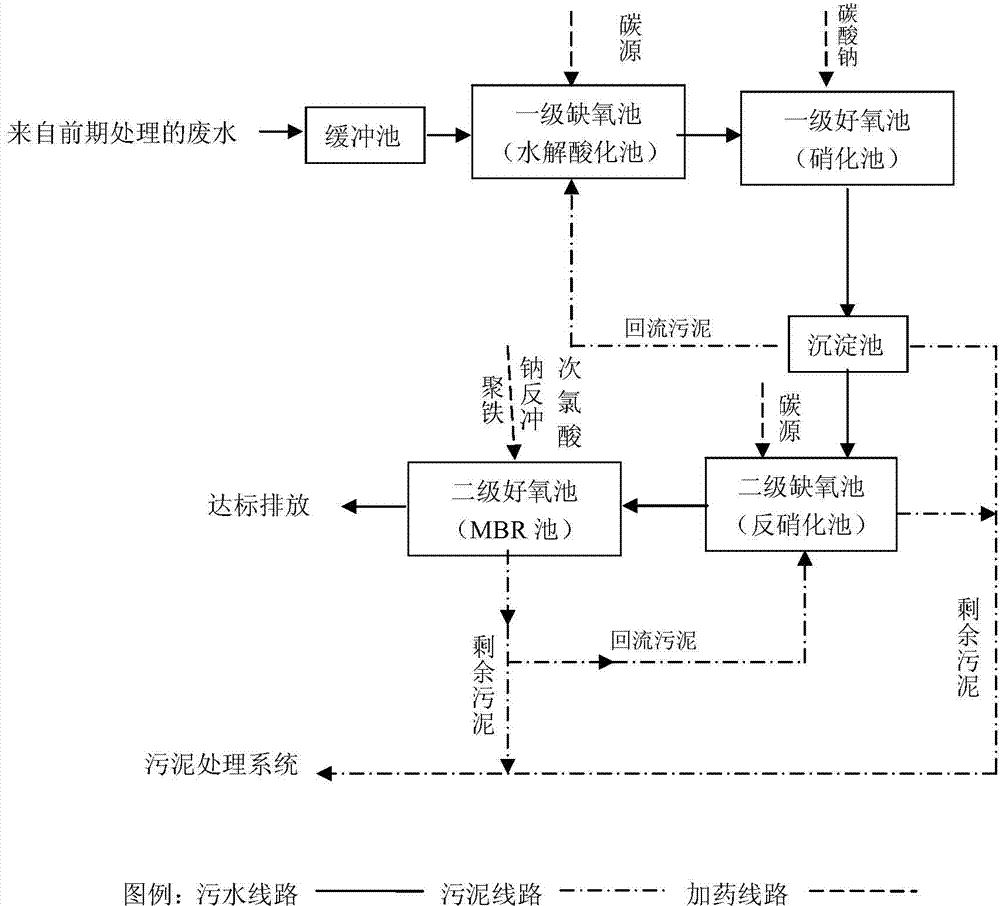

[0045] Such as figure 1As shown, the oilfield sewage is added to the buffer pool, and after the adjustment, cooling, and oil separation of the buffer pool, the oil floating on the liquid surface can be collected by the oil skimmer installed on the pool surface, and the sewage stays in the buffer pool The time is 16 minutes. Turn on the power supply of the lift pump, and the effluent from the buffer pool enters the cooling tower through the lift pump for cooling, cooling the sewage to 28-32°C, providing good temperature conditions for the subsequent biochemical treatment and ensuring the treatment effect.

[0046] Pass the cooled sewage into the first-level anoxic tank. Under the condition of anoxic, the acidified sludge is hydrolyzed and fully mixed with the wastewater, and the extracellular enzymes released by the fermentation bacteria are used to break the chain, so that the refractory macromolecules in the wastewater The organic matter is thoroughly digested into easily de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com