Chute structure for concrete precast semi-culvert

A technology of concrete and rapid trough, applied in the direction of side ditches/curbs, etc., can solve the problems of increased construction costs, increased labor costs, and increased construction periods, and achieve the effects of labor cost savings, easy repair, and rapid construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

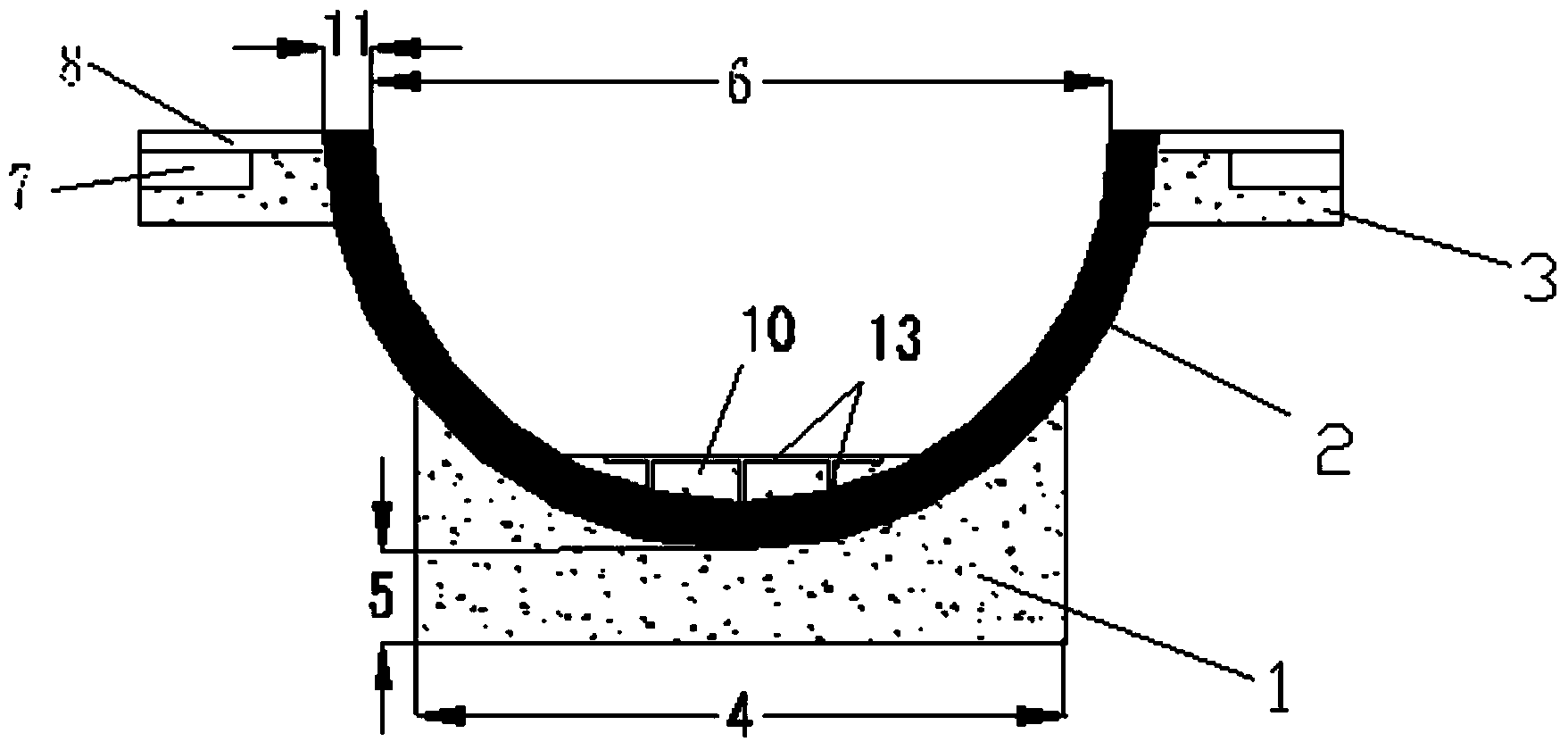

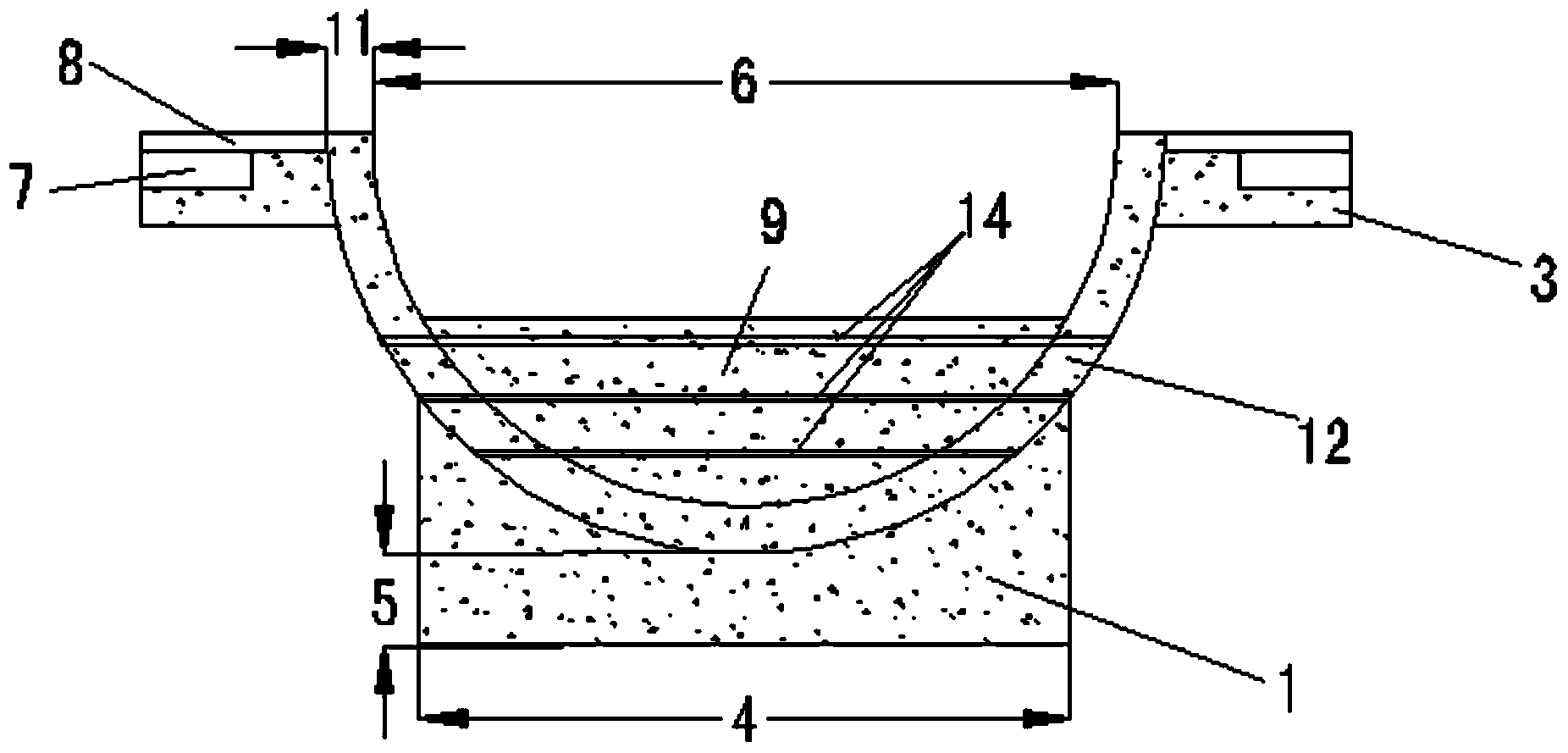

[0014] see figure 1 and figure 2 The structure of the prefabricated concrete half-culvert jet trough includes four parts: bottom fixed mortar 1, concrete prefabricated half-culvert pipe 2, large arc-shaped energy-dissipating steps 9, small-arc-shaped energy-dissipating steps 10, and two ditches 3 at the top. A concrete prefabricated half-culvert pipe 2 is arranged on the bottom fixed mortar 1, and a small arc-shaped energy-dissipating step 10 with an arc height of 40 mm to 60 mm is provided in the middle of the groove bottom of the single-section concrete prefabricated half-culvert pipe 2, preferably with a height of 50 mm. The joints of two concrete prefabricated half-culvert pipes 2 are provided with arc-shaped energy-dissipating steps 9 with an arc height of 180 mm to 220 mm. Bottom fixing mortar 1 adopts M7.5 cement mortar, width 4 shoul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com