Horizontal axis wind turbine with door fan blades and retractable rotor

A wind turbine and horizontal axis technology, which is applied to the direction of the wind engine, wind engine, wind engine control, etc., which is consistent with the wind direction, and can solve the problems of small fan output power, low wind blowing efficiency of blades, difficulty in hoisting, and danger of hoisting Large and other problems, to achieve the effect of improving output power and wind blowing efficiency, improving wind blowing ability and working ability, and reducing repair and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

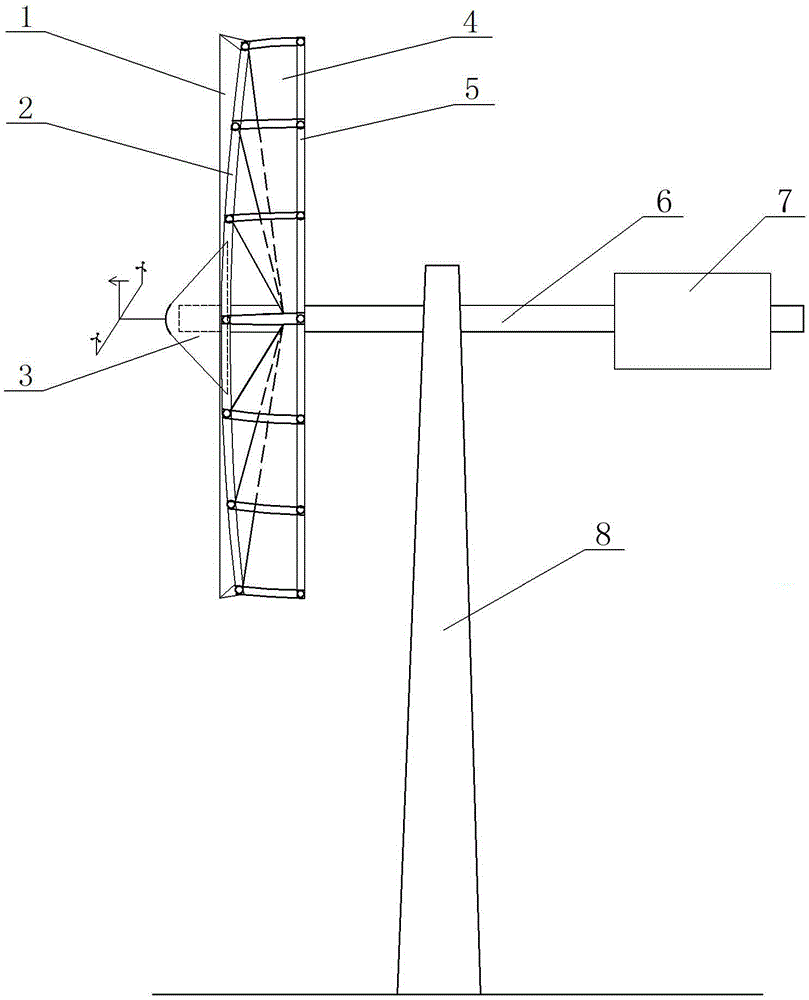

[0038] Depend on Figure 1 to Figure 8 It can be seen that the present invention includes a pole tower 8, a fan main shaft 6, a generator 7, a front frame, a rear frame, a blade 4, a blade shaft 12, an arc connecting rod, and an adjustment device; Assembled in the rear section of the fan main shaft 6;

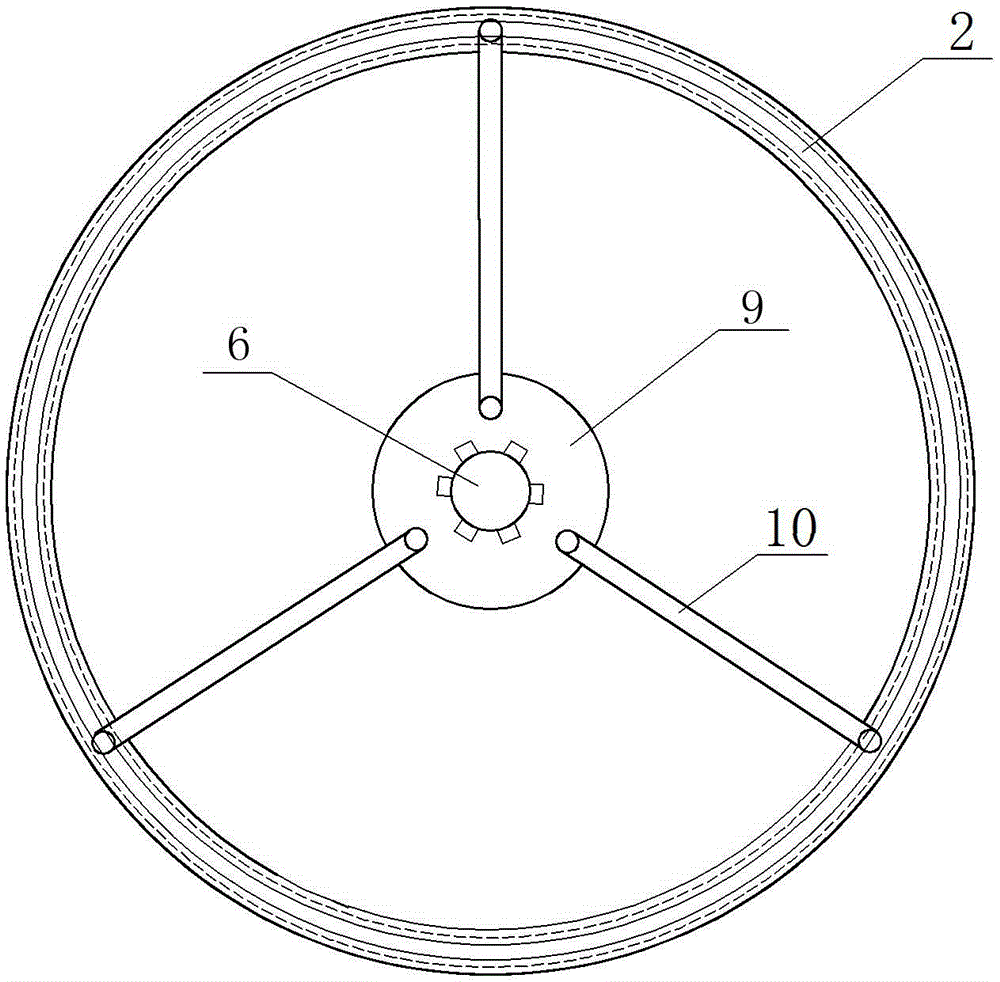

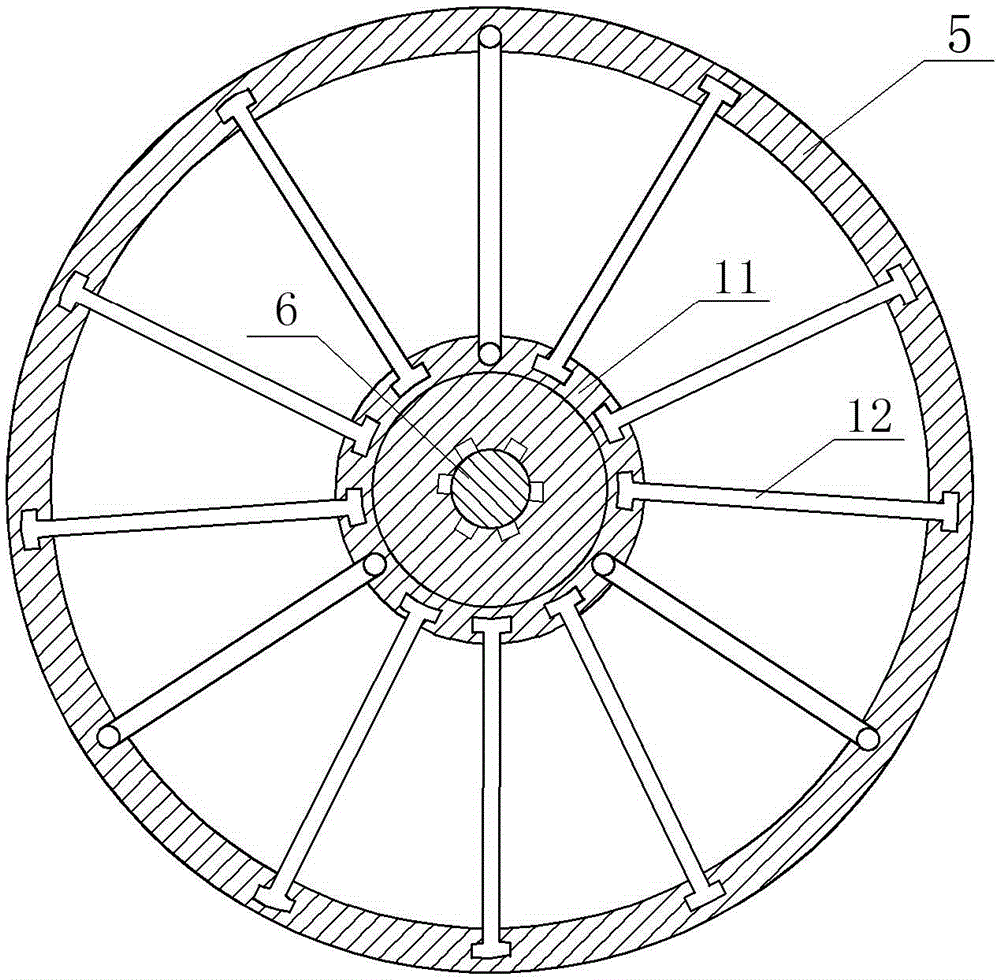

[0039] Both the front frame and the rear frame are composed of an inner frame and an outer frame, and the inner frame and the outer frame of the front frame and the rear frame are respectively connected by three support rods 10; the three support rods 10 of the front frame are hollow structures;

[0040] The inner frames of the front frame and the rear frame are sequentially set on the front section of the fan main shaft 6, the center holes of the front frame inner frame 9 and the rear frame inner frame 11 are provided with key grooves, and the front and rear frame inner frames are connected with the fan main shaft 6 through splines; The inner frame 11 of the rear frame and th...

Embodiment 2

[0049] The difference between this embodiment and Embodiment 1 is that the shaft hole of the blade 4 is provided with threads, and the blade shaft 12 and the blade 4 are threadedly matched so that the weight of the blade 4 acts on the blade shaft 12 evenly. This structure is suitable for blades with large weight. The adjustment device adopts an adjustment motor and a push-pull rod; the fan shaft 6 on the front frame side is equipped with three adjustment motors with fixed angles, and the power output mechanism of each adjustment motor is connected to the push-pull rod through a worm gear device. The other end of the pull rod is connected with the front frame inner frame 9 through a universal joint and a flange.

[0050] When adjusting the blade 4 angles, each adjusting motor runs simultaneously, driving the push-pull push-pull front frame of the front frame to move axially along the fan main shaft 6, approaching or moving away from the rear frame; The rod slides along the slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com