Integral Workpiece Having A Duct, And Manufacturing Method For Same

A one-piece, workpiece technology, which is applied in the field of manufacturing such workpieces, can solve the problems of expensive pipe manufacturing and achieve the effect of simplifying manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

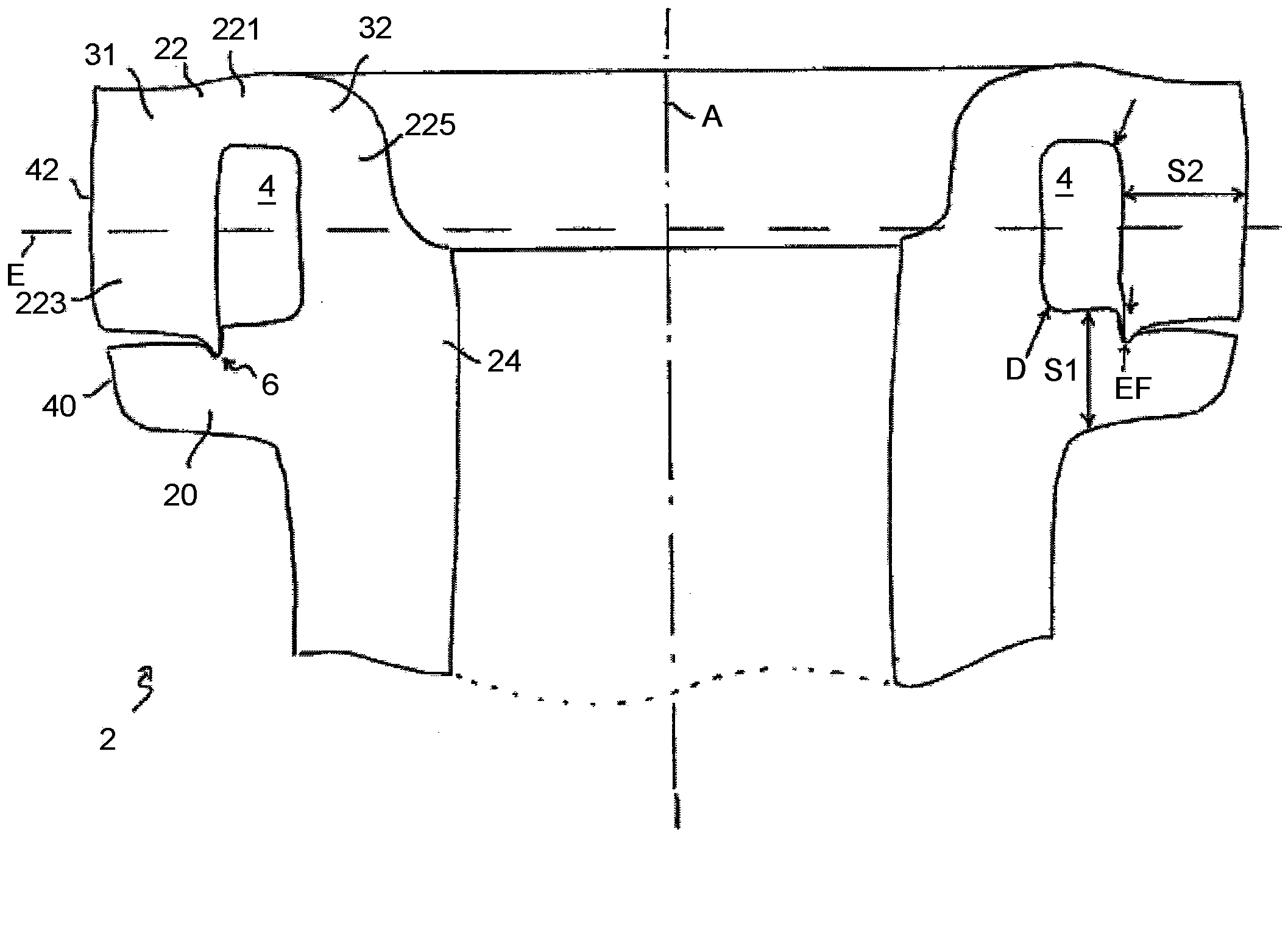

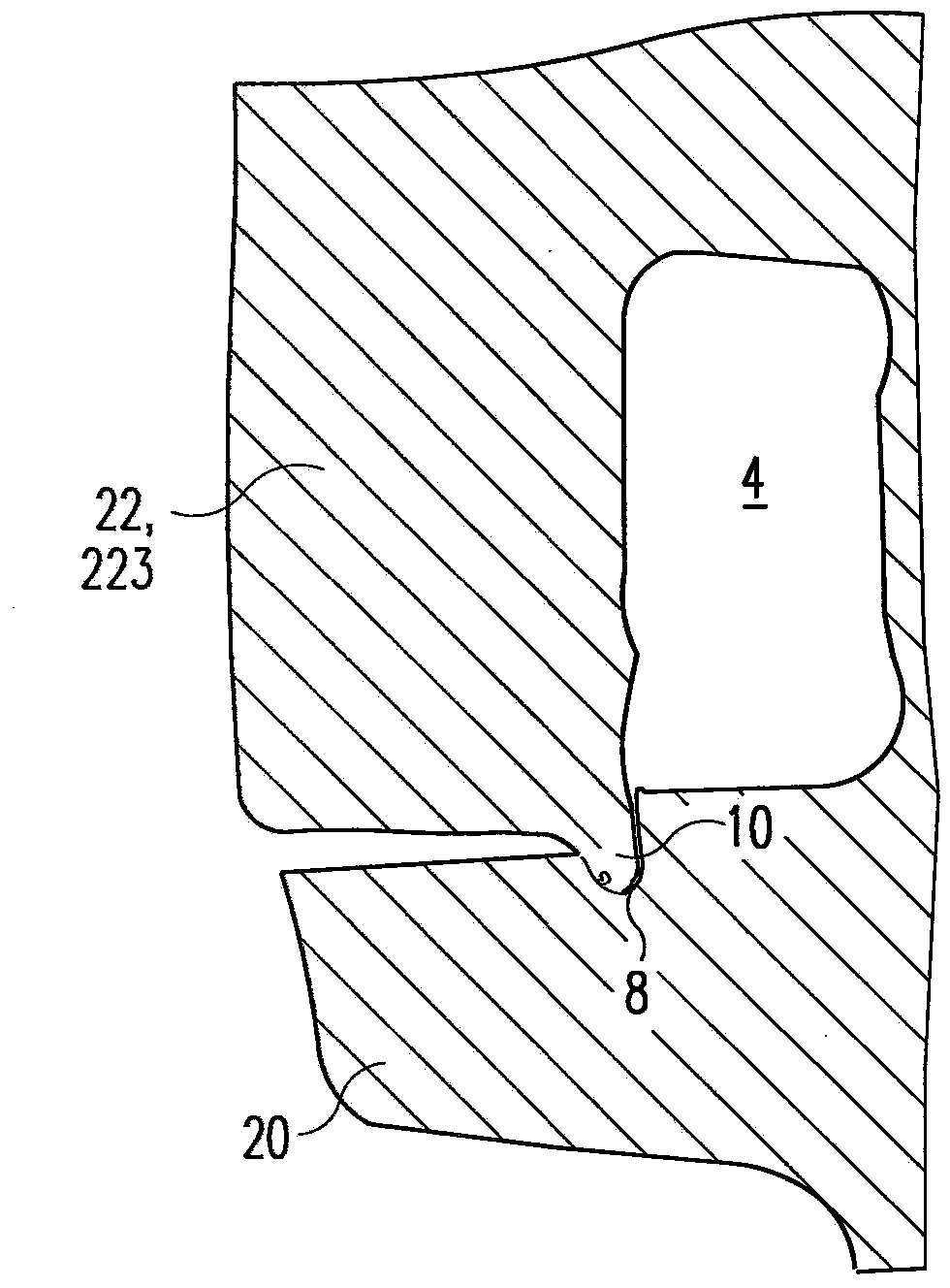

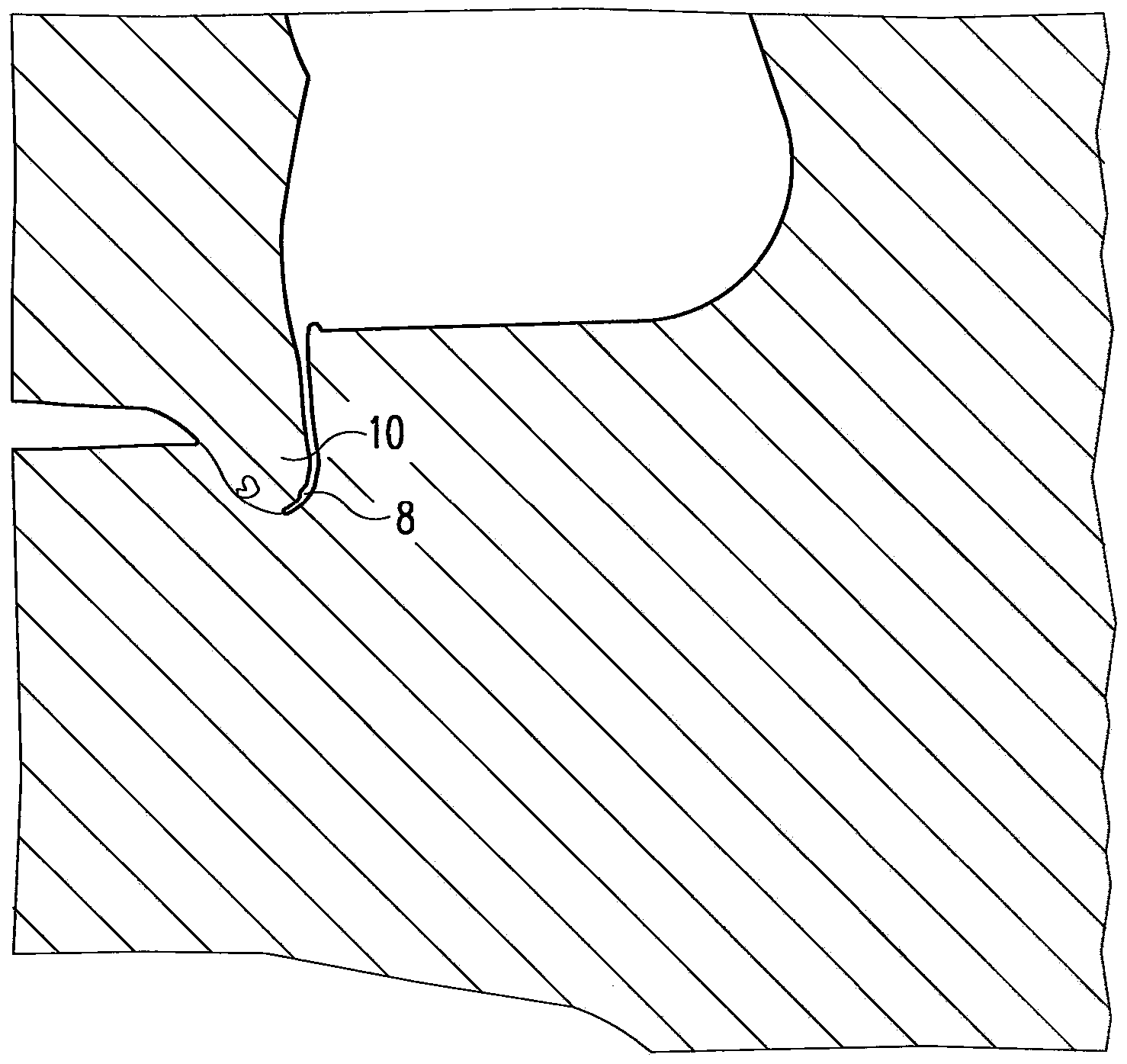

[0021] figure 1 shows a cross-sectional profile view of an embodiment of a workpiece 2 according to the invention; as in figure 1 As shown in , the workpiece 2 may be a tubular element or a substantially cylindrical element. Among them, refer to figure 1 As shown in , the workpiece 2 can be extended down a certain distance. The invention is suitable for a somewhat more general representation of the workpiece 2 , ie the workpiece 2 is fitted in the end region in a tubular or cylindrical shape. Among them, as an example figure 1 As shown, the workpiece 2 can be free from the inside in this end region, but can of course also be filled or closed.

[0022] The workpiece 2 is formed in one piece, it is in particular not designed as an assembly of two or more separate parts, but rather consists of a single part or part. The workpiece 2 is made of only one part. The workpiece can in particular be a steel part, but of course also an aluminum part. Steel components are basically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com