Cable fault on-line monitoring system

A technology for monitoring system and cable faults, which is applied in the field of monitoring systems, can solve the problems of long positioning delay, affecting power supply reliability, failure to locate faults, etc., and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

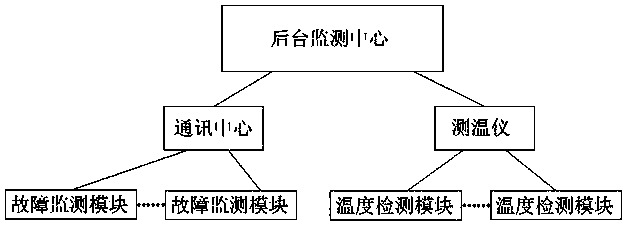

[0017] Such as figure 1 As shown, in this embodiment, the system of the present invention includes several sets of fault monitoring modules, a communication center, a background monitoring center, a thermometer and a plurality of temperature detection modules, wherein the fault monitoring modules are respectively installed on the cables to be detected in different positions. Each set of fault monitoring modules includes: respectively fixed on each single-phase wire in the three-phase cable, three current detection modules I for detecting short-circuit current and current temperature on each single-phase wire, and three current detection modules I fixed on three On the phase cable bus, the current detection module II that detects the ground current, load current and current temperature of the three-phase cable bus; the communication center is connected with the current detection module I and the current detection module II, and collects the short circuit of the cable Current, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com