Touch screen type batching control method and system for concrete batching plant

A control method and technology of a control system, applied in the field of automatic batching control, can solve the problems of poor real-time control effect and high communication reliability requirements, and achieve the effects of reducing intermediate communication links, reducing daily maintenance workload, and simplifying system wiring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

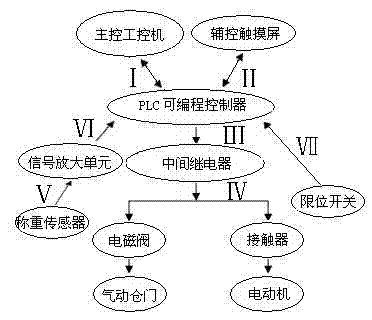

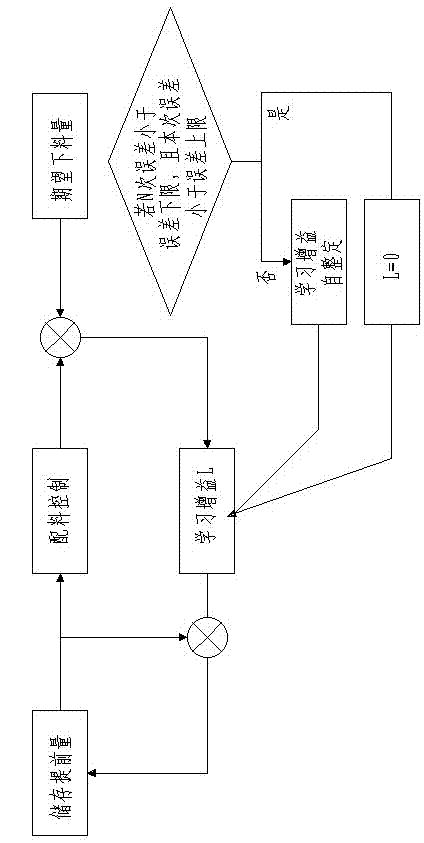

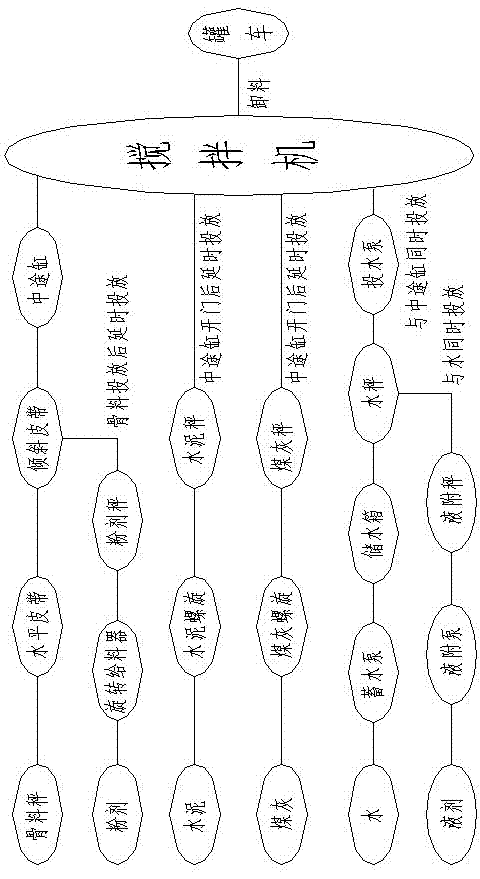

[0040] Such as figure 1As shown, the touch-screen batching control system of the concrete batching plant includes a host computer for setting and sending formula data and production parameter information required for batching. The host computer is composed of a main control industrial computer and an auxiliary control touch screen; The weighing sensor is used to detect the weight of raw materials sent from each raw material bin to the corresponding metering bin and generate real-time sending of raw material information; it is connected to the upper computer and the weighing sensor respectively, and is used to receive the information sent by the upper computer and the weighing sensor The PLC programmable controller that issues control instructions after logical judgment; is connected to the PLC programmable controller and the execution components in the concrete mixing plant respectively, and is used to execute the PLC programmable controller. The intermediate relay of the contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com