The acquisition and control method of rapid feed power and energy consumption of CNC machine tools

A rapid feed, CNC machine tool technology, applied in the direction of computer control, program control, general control system, etc., can solve the problems of rapid feed modeling, difficulty in rapid feed energy consumption assessment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Now, the present invention will be explained in detail in conjunction with the embodiments and the accompanying drawings.

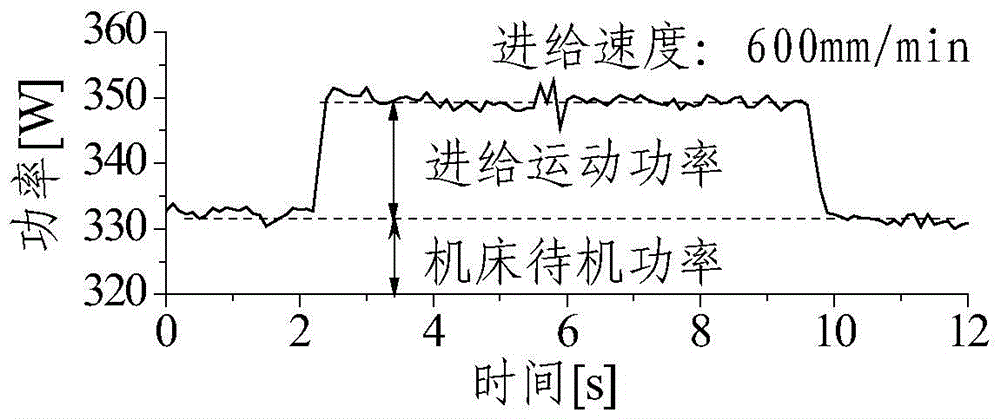

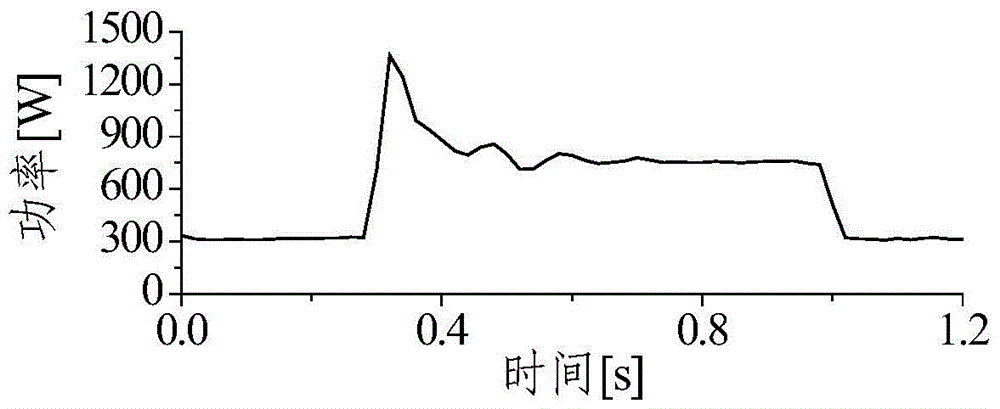

[0055] In one embodiment of the present invention, the Z-axis of a numerically controlled lathe is used as the selected feed axis, and the modeling method of feed power and energy consumption is described in detail.

[0056] Among them, the selected machine tool is the CK6153i CNC lathe of Jinan No. 1 Machine Tool Factory, and the feed speed set by the Z axis is f rmax =8m / min=133.3mm / s, feed distance L f 10mm and 30mm respectively.

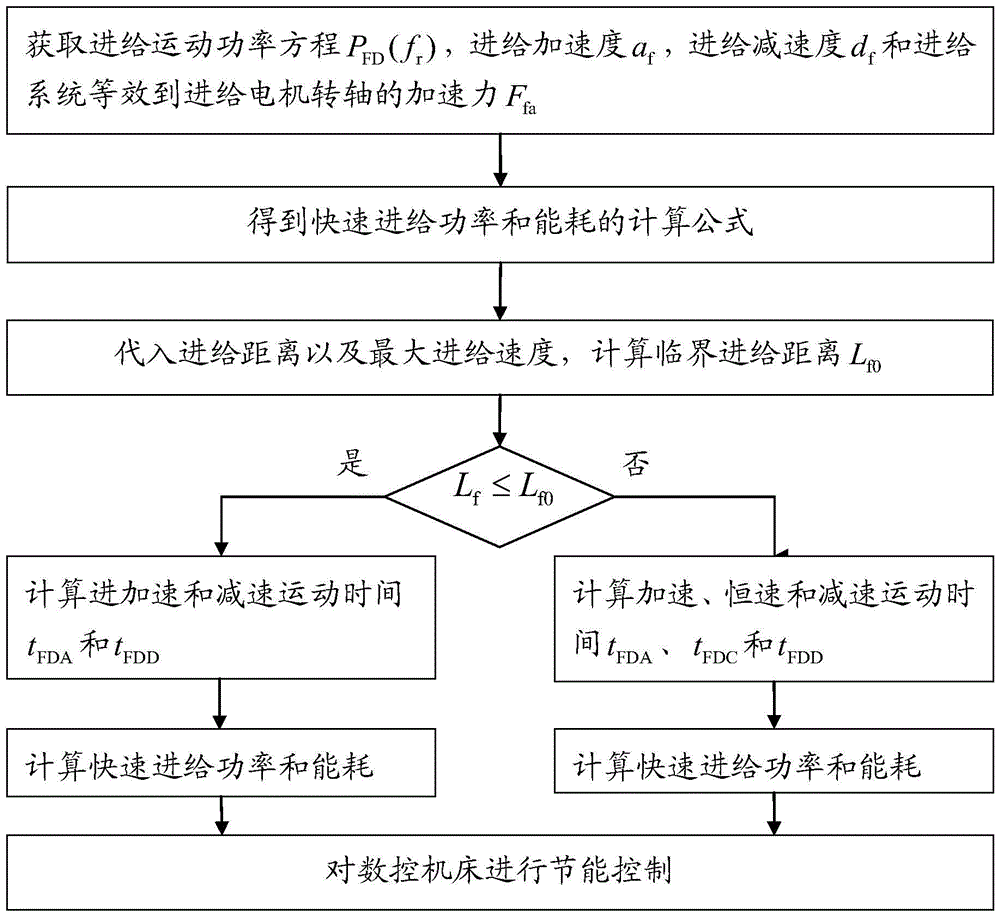

[0057] The acquisition and control method of the rapid feed power and energy consumption of the CNC machine tool in the current embodiment of the present invention are as follows: figure 1 shown, including the following steps:

[0058] Step 1. Select a feed axis to be controlled in the CNC machine tool, set the maximum feed speed of the feed axis, obtain the feed motion power equation of the feed axis and the param...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com