Energy-saving control method and control system for oil field pumping unit

An energy-saving control and pumping unit technology, applied in general control systems, control/regulation systems, program control in sequence/logic controllers, etc. Small and other problems, to achieve the effect of precise positioning control and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

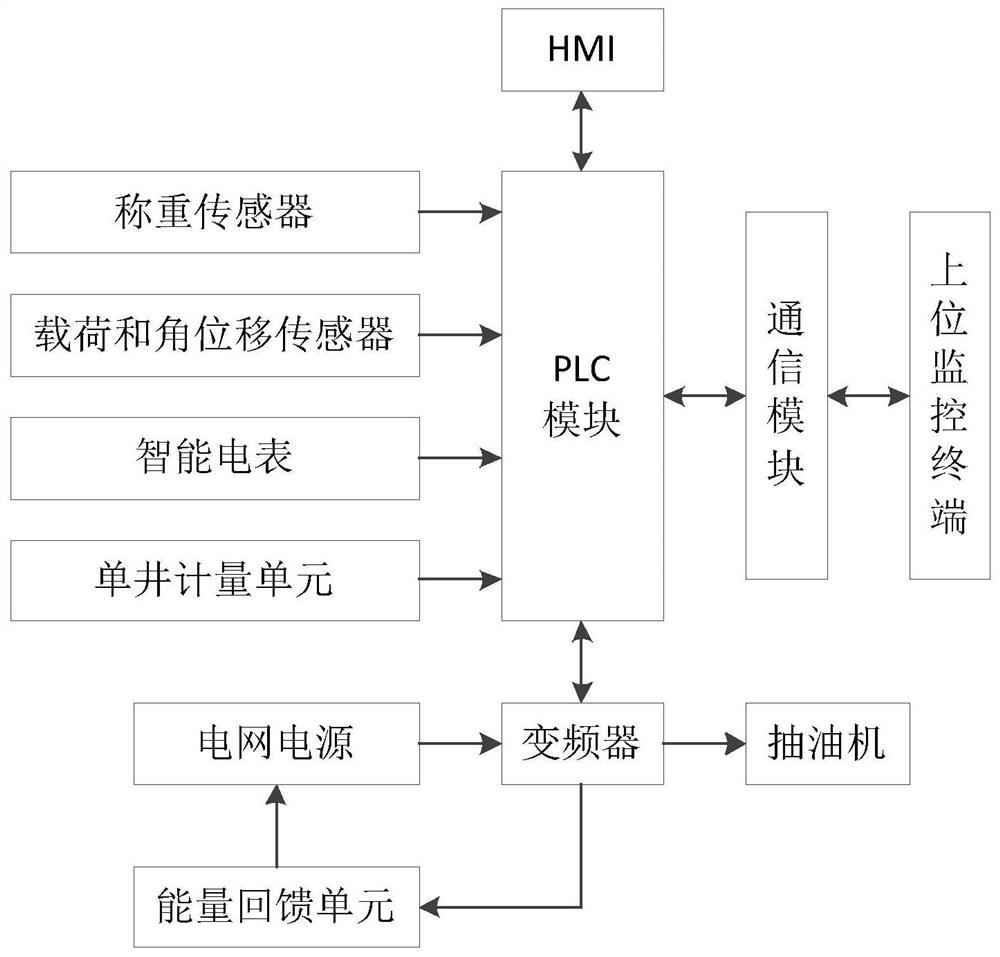

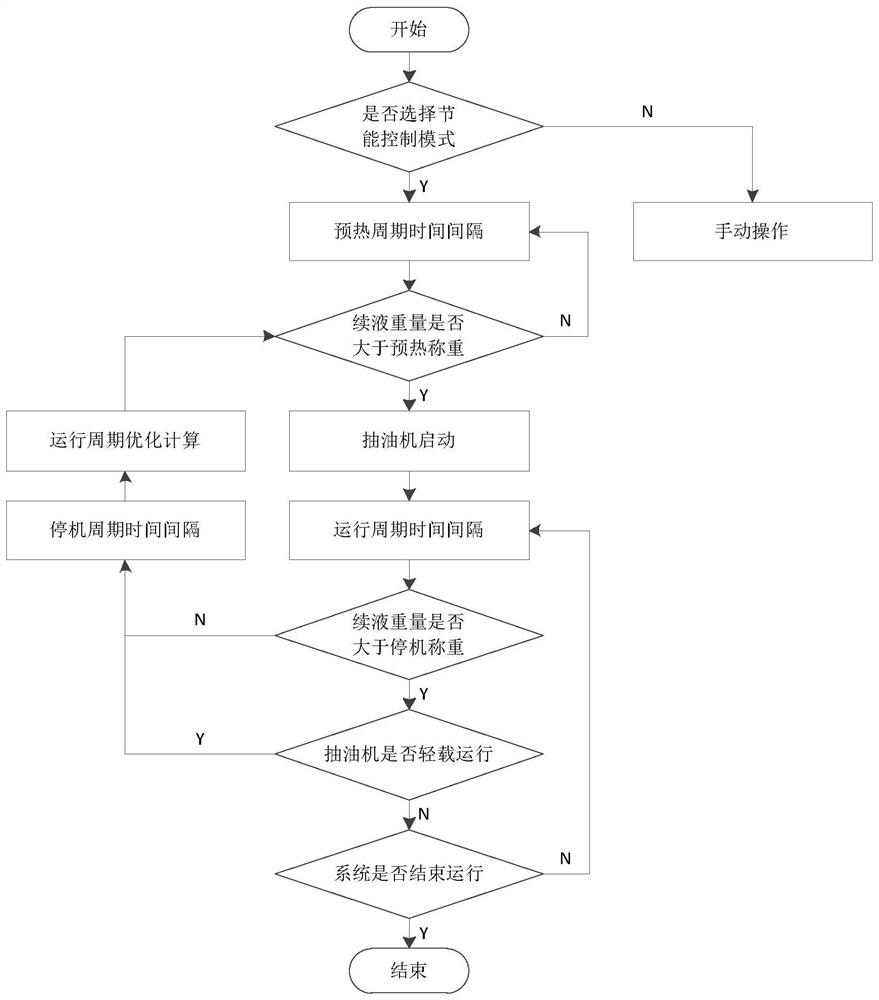

[0034] Such as figure 1 As shown, an oil field pumping unit energy-saving control system includes a PLC module, a frequency converter, an energy feedback unit, a data acquisition unit, an HMI, and an upper monitoring terminal. The PLC module, frequency converter, energy feedback unit, and HMI are set on the In the control cabinet of the control room, the frequency converter and HMI are connected to the PLC module through RS485; the data acquisition unit includes a load cell, a load and angular displacement sensor, a smart meter and a single well metering device, The sensor is arranged beside the pumping unit, connected with the oil inlet and outlet pipes, connected with the PLC module through the analog input module, and used for the detection of the continuous liquid weight (that is, the liquid output of the oil well); the load and angular displacement sensors are arranged at the pumping unit On the beam of the pumping unit, it is connected with the PLC module through the Zig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com