Epitaxial growth method for improving luminous efficiency of LED

A technology of epitaxial growth and luminous efficiency, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve problems such as the influence of luminous efficiency, unfavorable material growth, etc., to reduce the electron spillover effect, improve the growth quality, and reduce the injected kinetic energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

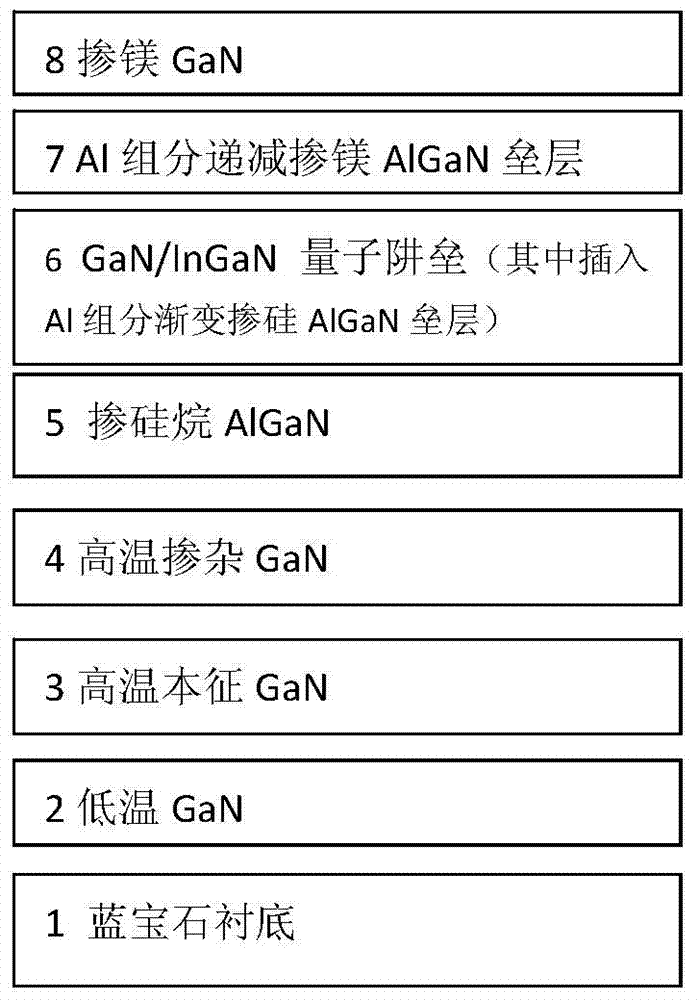

[0040] 1. After cleaning the sapphire substrate, put it into the MOCVD equipment and bake it at 1100°C for 10 minutes.

[0041] 2. Lower the temperature to 550°C to grow a low-temperature GaN layer with a thickness of 20nm, and the growth pressure is 400torr.

[0042] 3. Raise the temperature to 1020°C to grow a layer of undoped GaN layer with a thickness of 1um at high temperature, and the growth pressure is 300torr.

[0043] 4. A layer of 0.5um n-type GaN layer doped with SiH4 is grown at a temperature of 1030°C and a pressure of 200torr.

[0044] 5. Grow a 20nm silane-doped n-type AlGaN layer at a temperature of 1030°C and a pressure of 200torr.

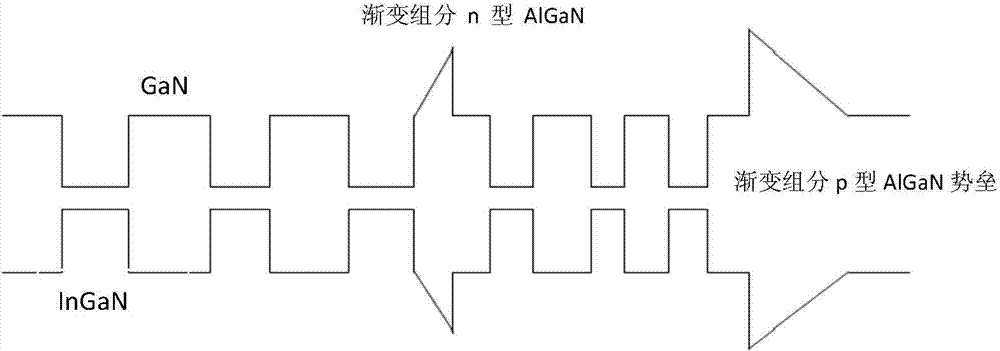

[0045] 6. In a nitrogen atmosphere, grow a layer of 12nm GaN at 850°C and a layer of 3nm InGaN quantum well barrier structure at 750°C at 400torr, and grow for 3 cycles.

[0046] 7. Then the temperature rises to 950°C, turns on SiH4, and grows a layer of AlGaN. During the growth, the molar flow rate of Al gradually increases fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com