Method and device for supplementing oil to electrified transformer sleeve pipe

A transformer bushing and oil replenishment device technology, which is applied to transformer/inductor parts, switchgear, circuits, etc., can solve the problems of high-altitude operation, cumbersome switching operation, and reduced insulation strength outside the bushing. Achieve high work safety and reliability, reduce the risk of total stop, and achieve good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

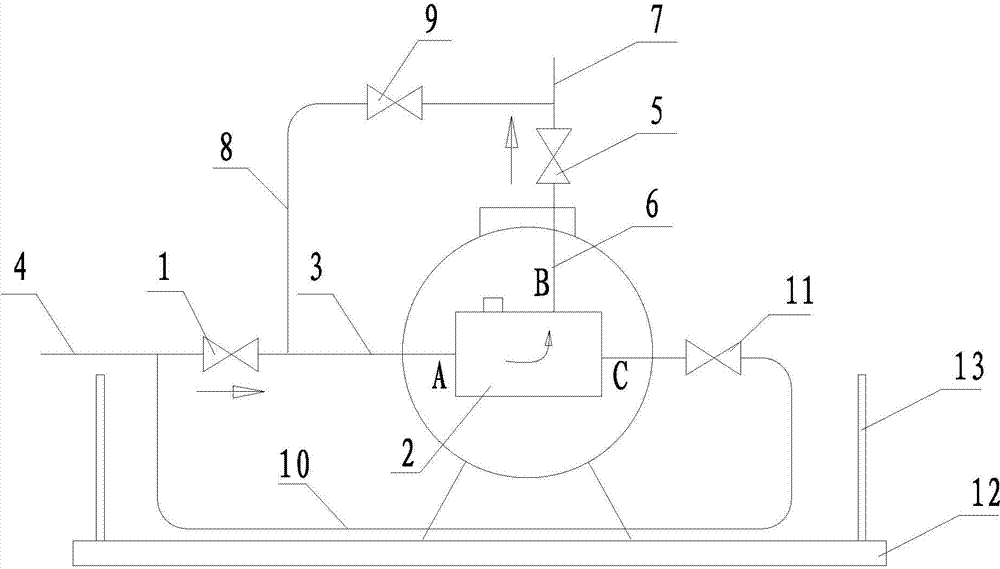

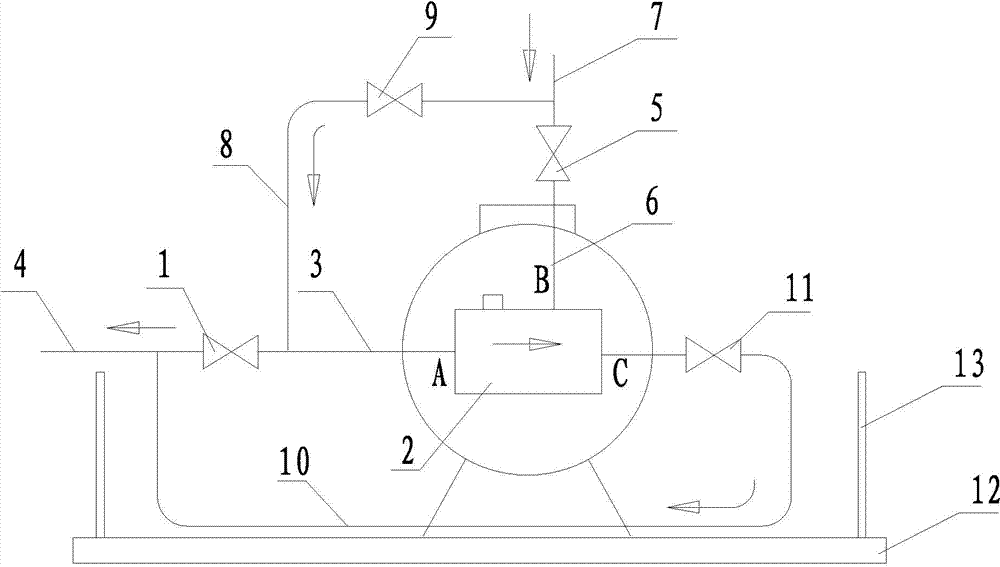

[0022] The specific embodiments of the present invention will be further described below in conjunction with the drawings:

[0023] see figure 1 , figure 2 , Is a schematic diagram of the structure of an embodiment of the replenishing device of the present invention. One end of the oil injection valve 1 is connected to the oil inlet A of the self-priming pump 2 through the oil inlet pipe 3, and the other end of the oil injection valve 1 is connected to the device inlet 4; oil injection valve 2 5 One end is connected to the outlet B of the self-priming pump 2 through the outlet pipe 6, and the other end of the oil injection valve 5 is connected to the outlet 7 of the device; the outlet 7 of the device communicates with the inlet pipe 3 through the oil return pipe 8 and the oil return pipe 8 An oil return valve 9 is provided. The oil outlet pipe 6 is connected to the inlet 4 of the device through an oil return pipe 10, and an oil return valve 11 is provided on the oil return pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com