Device used for dismounting valve motor core

A technology of iron core and valve, applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problem of low maintenance pass rate, and achieve the effect of improving pass rate, convenient installation and use, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

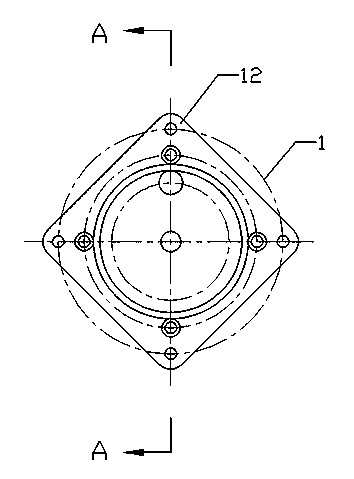

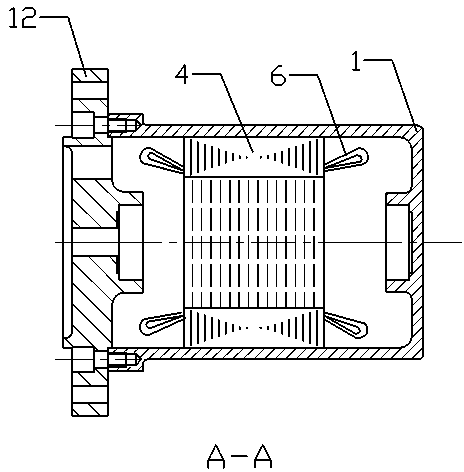

Image

Examples

Embodiment

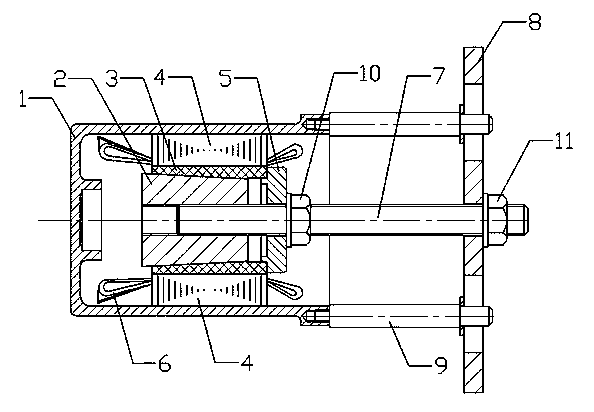

[0034] Choose two round steels with a diameter of 12mm and a length of 110mm to make the steel column 9, choose a 180mm×80mm×12mm steel plate to make the outer pressure plate 8, choose a M16×180mm screw rod 7 to form a bracket unit, and drill a 17mm hole in the middle of the outer pressure plate 8 The hole is the center hole, and a round hole with a diameter of 10mm and a length of 30mm is milled on both sides of the hole, which is the installation hole.

[0035] A bakelite sleeve 3 with four grooves with an inner taper of 1:10, a steel sleeve 2 with an outer taper of 1:10, and a gland form a taper sleeve combination unit, and the set steel sleeve 2 and bakelite sleeve 3 increase friction between them.

[0036]During the specific operation, screw the adapter nut II11 on the outer screw rod 7 of the outer pressure plate 8 to drive the screw rod 7, and the movement of the screw rod 7 drives the taper sleeve expansion unit to move to the outlet end of the valve motor base, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com