A kneading knife for an extruder

A technology of extruder and knife body, which is applied in application, feed, grain processing, etc., can solve the problems of low conveying efficiency, poor feed quality, low production capacity, etc., and achieve reduced production power consumption, wide application range, and less time consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

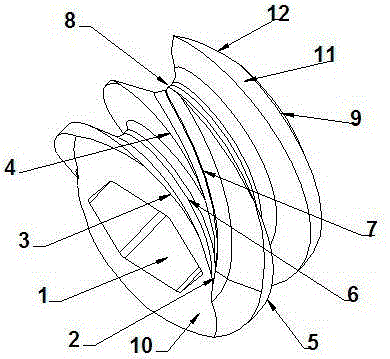

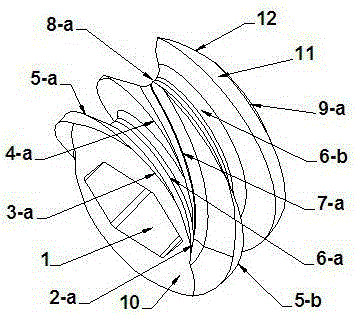

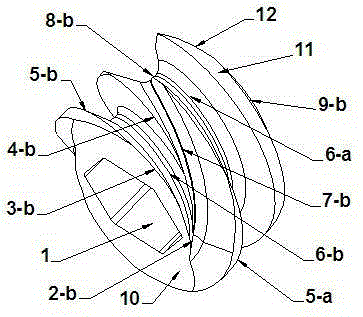

[0020] see figure 1 , figure 1 Schematic diagram of the overall structure of the present invention, a kneading knife for an extruder, the kneading knife includes a material guide port 2, a storage blade 3, a rotary cutting blade 4, a kneading blade 5, a slow kneading groove 6, and a fast kneading groove 7. Discharge port 8, discharge blade 9, cutter outer circle 11, the above-mentioned components are arranged in groups, the number is two groups, and each group is evenly distributed on the circumference of the kneading knife; the kneading knife also includes Inner mounting hole 1, feed end 10, and discharge end 12; the material guide port 2 and the storage blade 3 are located at the feed end 10; the fast kneading groove 7 and the slow kneading groove 6 in the same group work together It starts from the material guide port 2 of this group, and terminates at the position where the discharge port intersects with the slow kneading groove and the fast kneading groove in the other g...

Embodiment 2

[0024] As another form of expression of the present invention, see figure 1 — Figure 6 , the screw pitch of the above-mentioned slow kneading tank 6 and the fast kneading tank 7 is in multiples, the pitch ratio is 1:2, and the unloading speed of the slow kneading tank 6 and the fast kneading tank 7 is 2:1. The pitch relationship of the fast and slow kneading grooves is set to 2:1, which further ensures the cooperation between the fast and slow kneading grooves, the rotary cutting blade and the kneading blade, thereby ensuring that the kneading knife has stronger kneading shear, further improving the The production efficiency of the extruder greatly improves the feed quality. The rest of the structures and advantages are exactly the same as in Embodiment 1.

Embodiment 3

[0026] As another form of expression of the present invention, the outer circumference 11 of the cutter is configured as a cylindrical or conical structure. The rest of the structures and advantages are exactly the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com