Production system of light and textile industry clothing products

A technology of textile and garment production system, applied in the field of production system of light industrial textile and garment products, can solve the problems of inability to find production information, inability to realize real-time monitoring of the production of cut pieces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

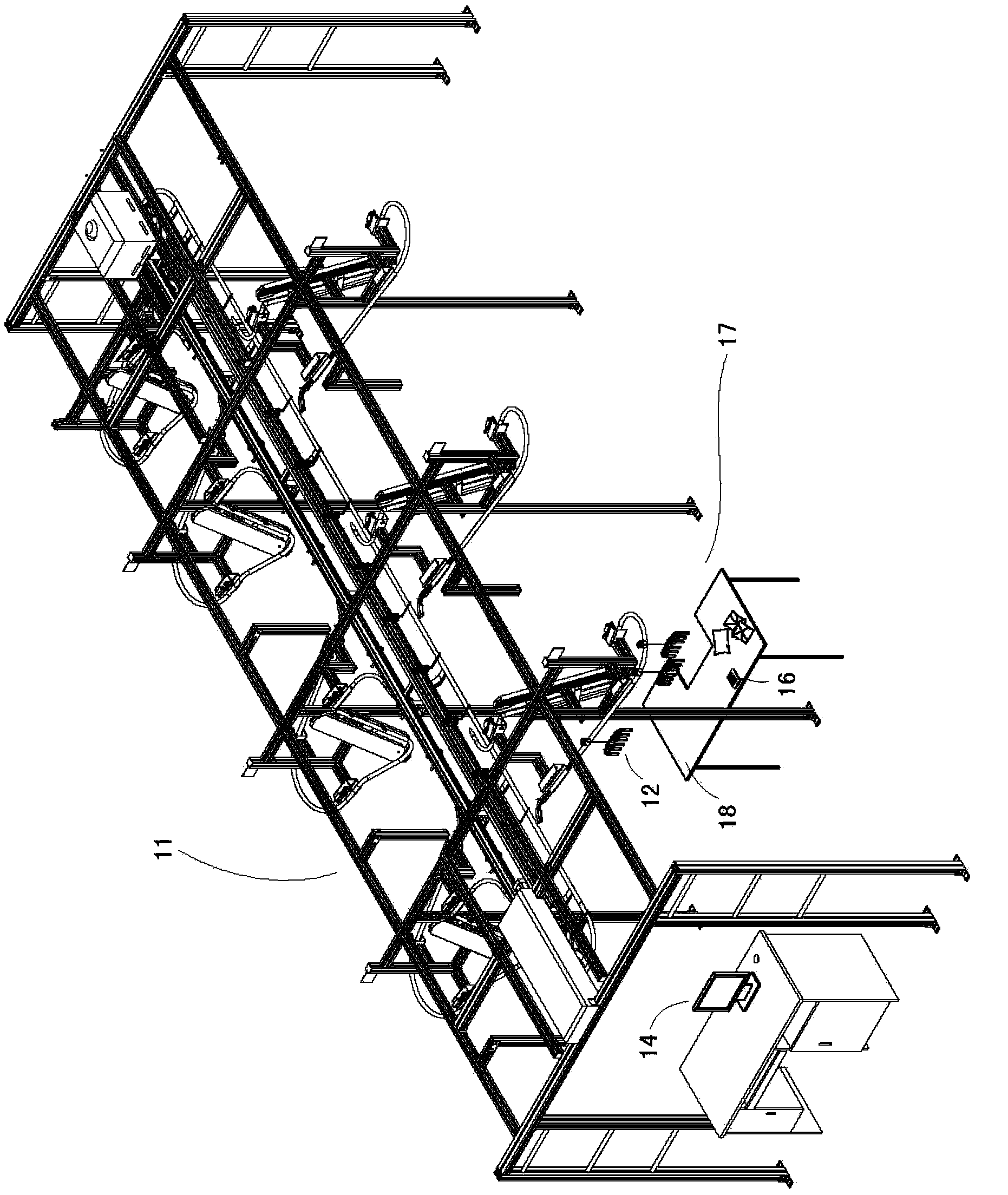

[0019] figure 1 Shown is a schematic diagram of the structure of a part of the light industrial textile and clothing product production system according to the first embodiment of the present invention. figure 1 The shown production system 1 for light industrial textile and clothing products includes a hanging device 11, and the hanging device 11 includes at least one material carrying device 12 for carrying materials (such as cut pieces) used for making clothes, and the material carrying device 12 can be a clothes hanger or a hanging basket or any other device that can carry the materials used for making clothes. figure 1 shown). Each material carrying device 12 has its own identification information, such as the ID of the material carrying device 12 . The specific implementation may be to set the RFID card 13 on each material carrying device 12, and store the respective identification information of each material carrying device 12 in the RFID card 13, or set a barcode on ...

no. 2 example

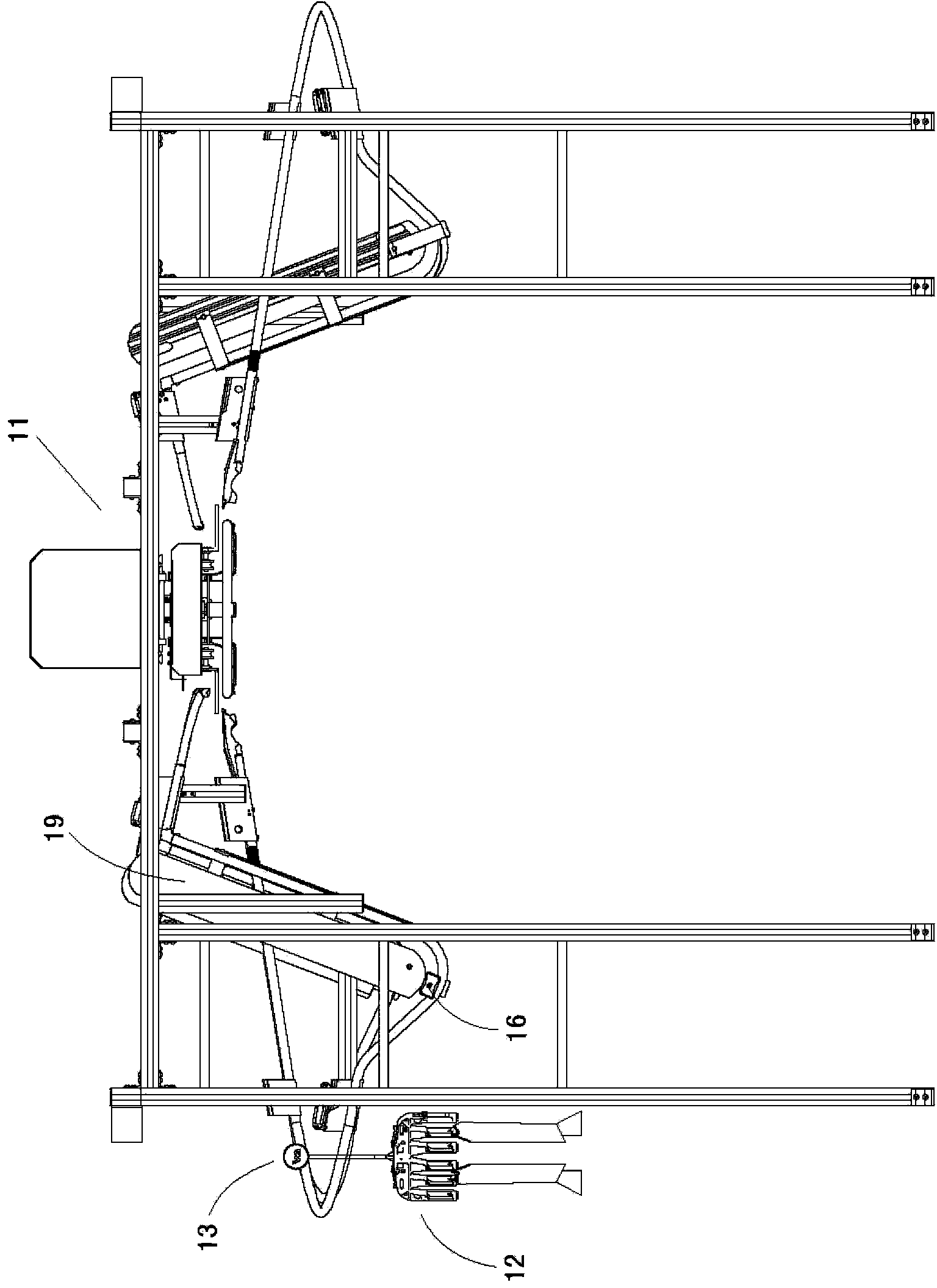

[0034] figure 2Shown is a schematic diagram of the structure of a part of the light industrial textile and clothing product production system according to the second embodiment of the present invention. The second embodiment differs from the first embodiment only in the installation position of the information reading device. Only the differences between the second embodiment and the first embodiment will be described in detail below, and the similarities between the second embodiment and the first embodiment will not be described repeatedly.

[0035] In the first embodiment, the information reading device 16 is movably placed on the table 18 of the mounting station 17, and the worker can move the position of the information reading device 16 as needed. In the second embodiment, the information reading device 16 is fixedly disposed below the lifting device 19 for lifting the material carrying device 12, such as figure 2 shown. The information reading device 16 reads the i...

no. 3 example

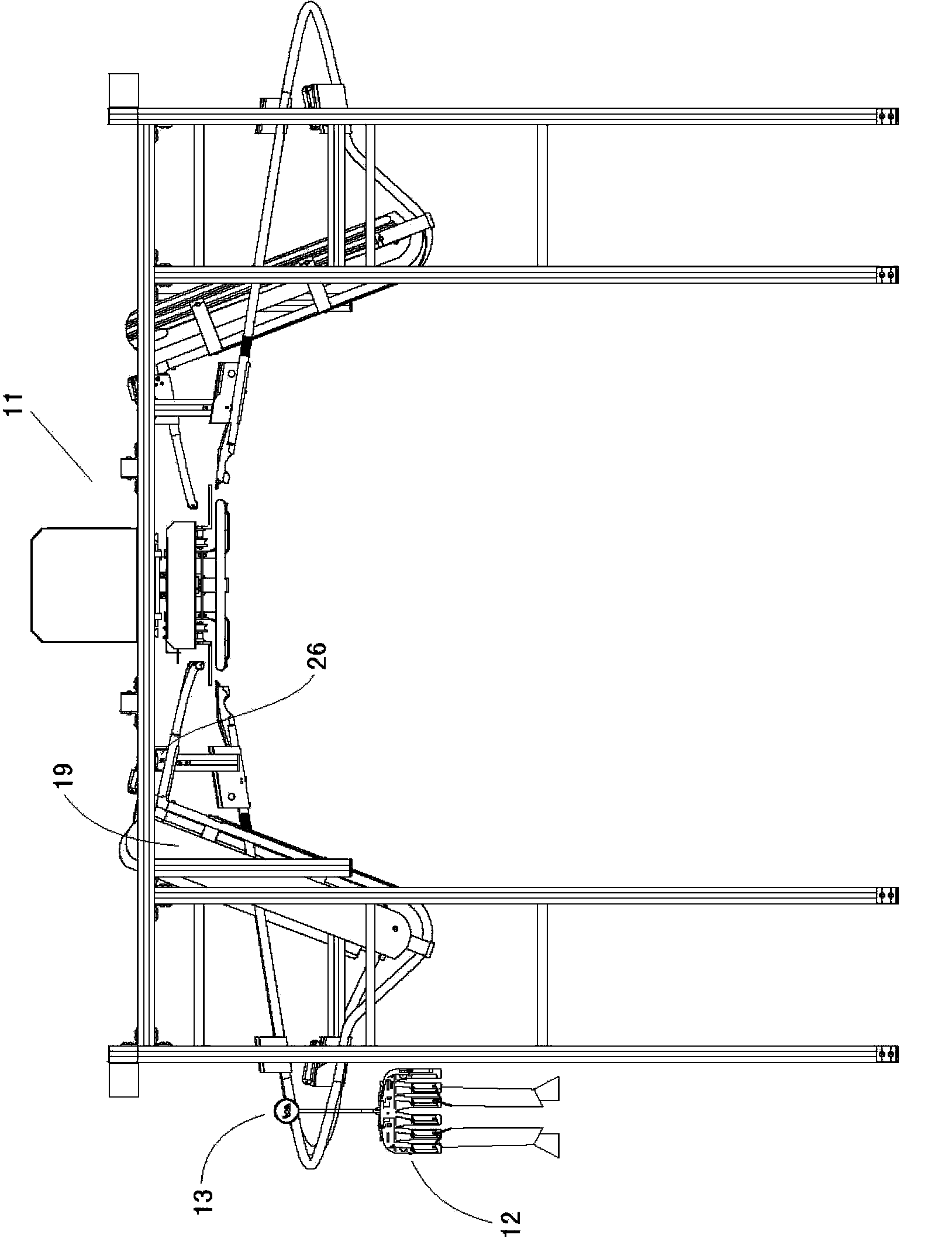

[0037] image 3 Shown is a schematic diagram of the structure of a part of the light industrial textile and clothing product production system according to the third embodiment of the present invention. The third embodiment differs from the first embodiment only in the number and arrangement positions of the information reading devices. Only the differences between the third embodiment and the first embodiment will be described in detail below, and the similarities between the third embodiment and the first embodiment will not be described repeatedly.

[0038] In the light industrial textile and clothing product production system of the third embodiment, two information reading devices are included. The information reading device 26 is fixedly arranged above the lifting device 19 for lifting and lowering the material carrying device 12, such as image 3 shown. In addition, the information reading device 36 is movably placed on the table 18 of the mounting station 17, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com