Anti-lightning ventilation pipeline structure of fuel tank of aircraft

A technology for venting pipelines and aircraft fuel tanks, applied in the direction of fuel tank safety measures, etc., can solve problems such as major disaster hazards, threatening flight safety, and no backfire prevention, and achieve the goal of eliminating disaster hazards, ensuring flight safety, and improving lightning protection effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

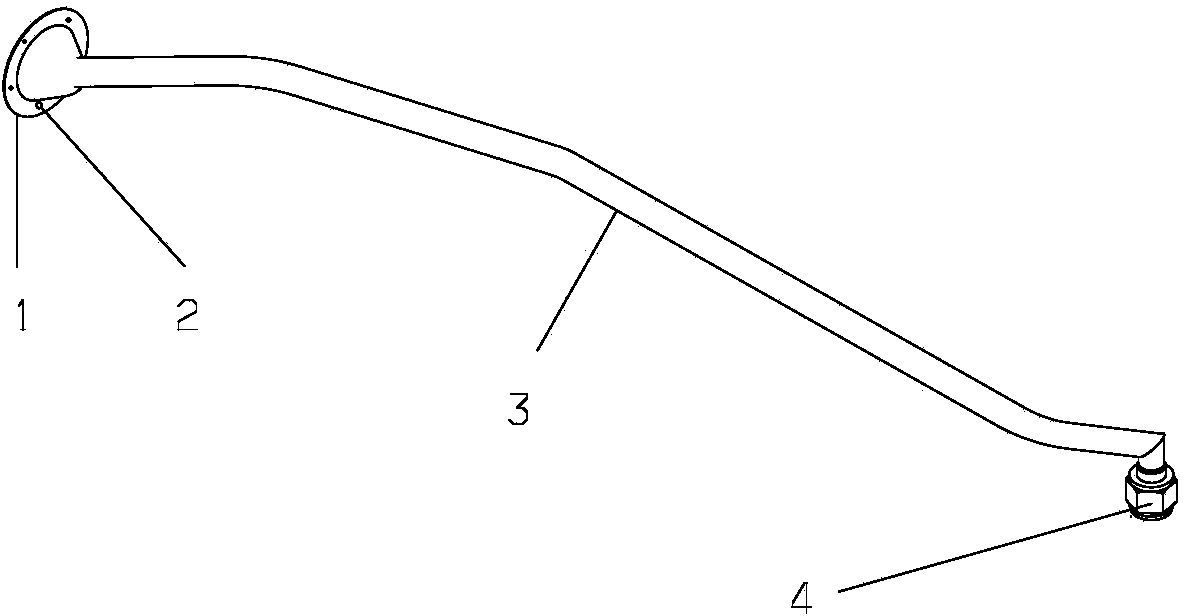

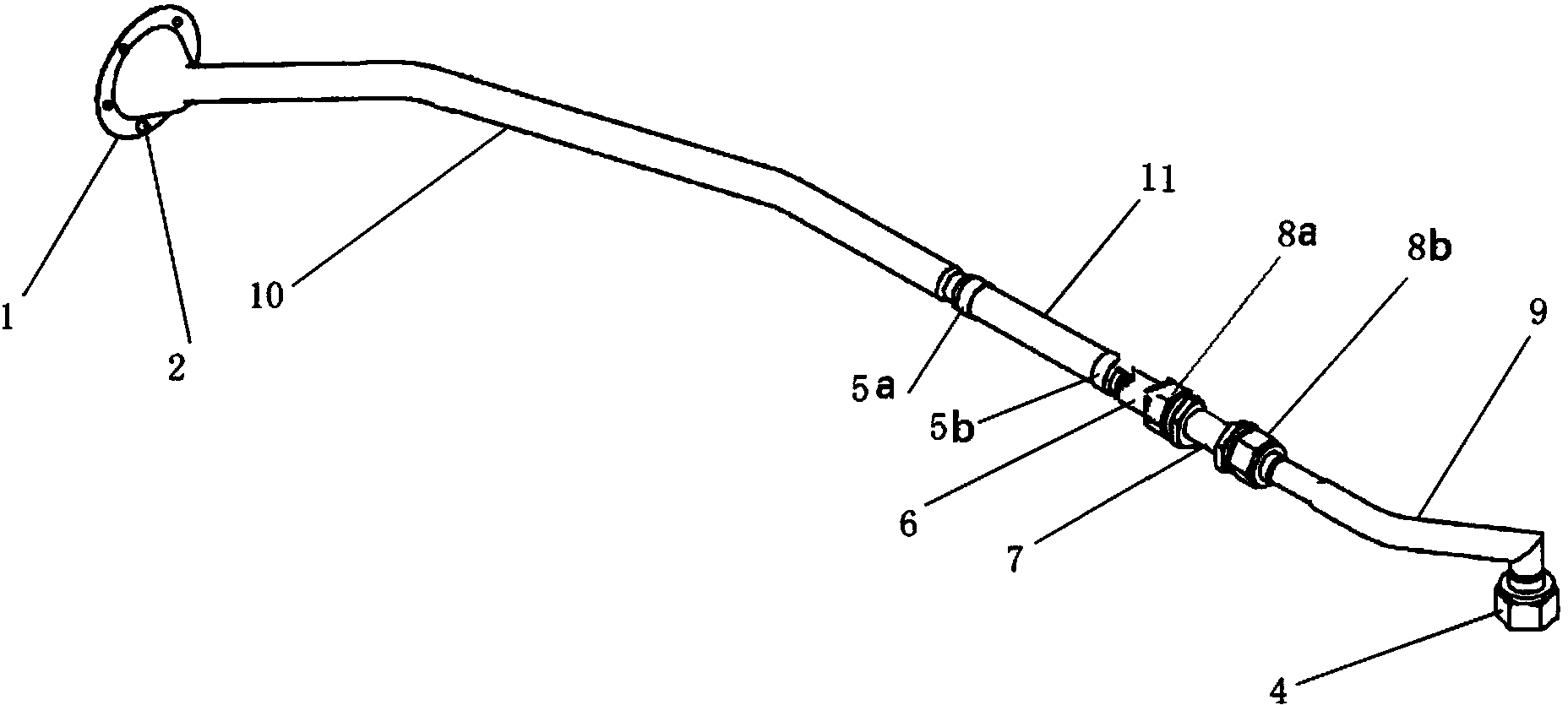

[0008] The present invention will be described in further detail below. see figure 2 , the anti-lightning ventilation pipeline structure of the aircraft fuel tank, including the trumpet-shaped pipe joint 1, the connecting screw 2, the ventilation pipeline and the first outer casing joint nut 4, the left end of the trumpet-shaped pipe joint 1 and the ventilation pipeline is welded as a whole, the first The outer casing joint nut 4 and the right end of the ventilation pipeline are connected through a conduit flare, and there is a flange with a screw through hole on the horn-shaped pipe joint 1, and the horn-shaped pipe joint 1 is fixed on the aircraft skin by connecting screws 2; It is characterized in that the ventilation pipeline is composed of a first hard tube 10, a first clamp 5a, a rubber insulating hose 11, a second clamp 5b, a second hard tube 6, a second outer casing joint nut 8a, and an anti-backlash An insulated ventilation pipeline formed by connecting the fire pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com