Method for manufacturing novel SMC composite material outdoor power distribution box

A composite material and manufacturing method technology, applied in the field of manufacturing of new SMC composite outdoor distribution boxes, can solve problems such as poor electrical conductivity and poor electromagnetic shielding effect, and achieve excellent electrical conductivity, low cost, and easy installation and disassembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

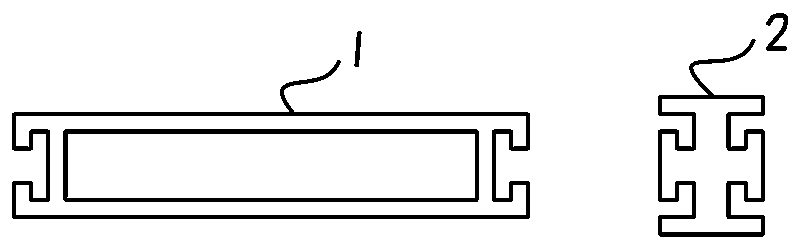

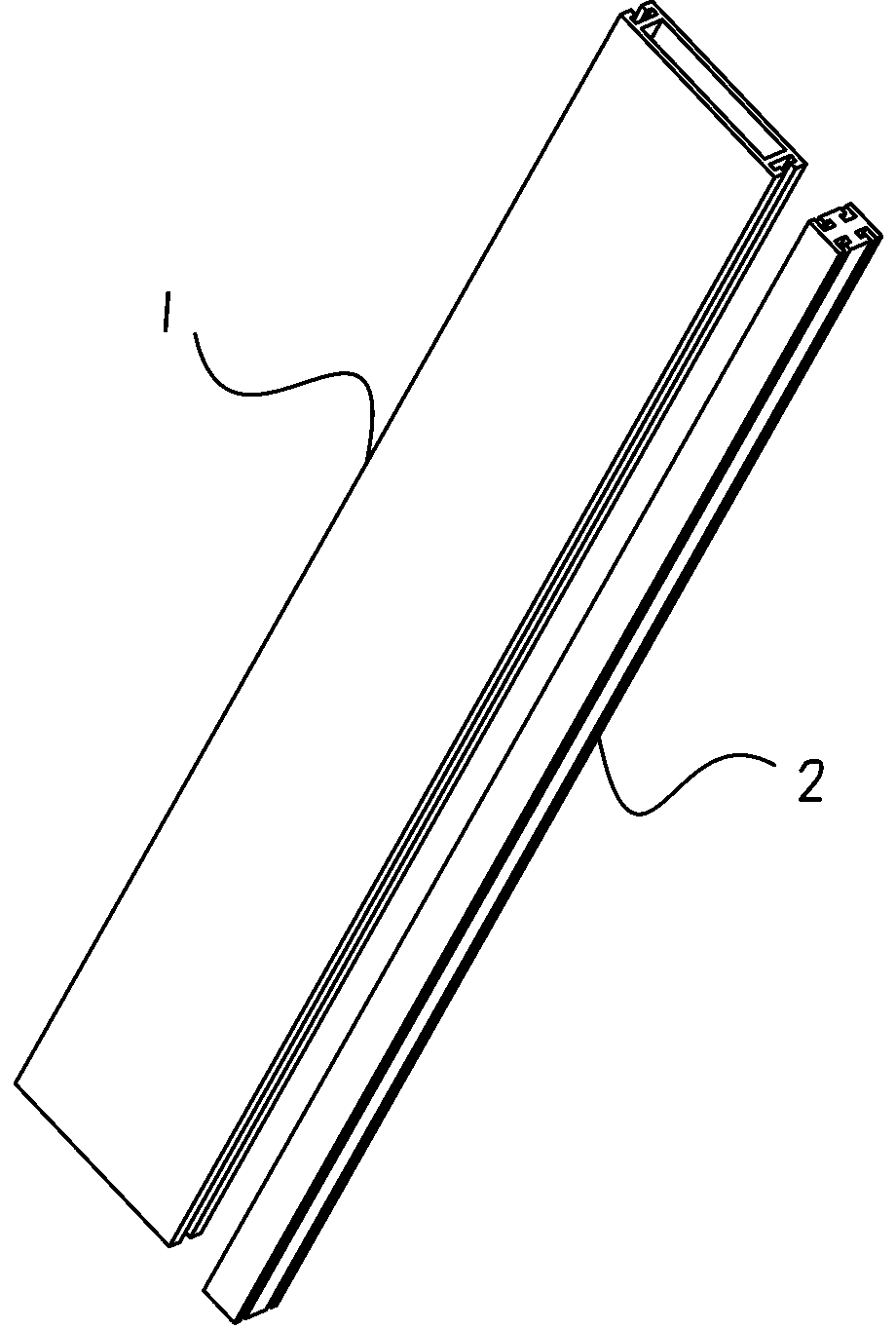

[0032] The invention discloses a manufacturing method of a novel SMC composite material outdoor distribution box, such as figure 1 with image 3 As shown, on the basis of the main structure of the conventional SMC composite material, the surface of the glass fiber is metallized, and a certain amount of iron-based amorphous alloy powder and iron-based nanocrystalline alloy powder are added to the resin matrix to modify it. , through the pultrusion process to make a new type of SMC composite material slats and further assemble it into a new type of SMC composite material outdoor distribution box, such as Figure 5 shown.

[0033] The specific technical scheme is as follows:

[0034] The mass percentage of impregnating resin is obtained from the following components: 100 parts of resin matrix, 10 parts of filler, 3 parts of release agent, 1 part of curing agent, 10 parts of low shrinkage agent, 2 parts of antioxidant, 4 parts of iron-based amorphous alloy powder 4 parts, 4 par...

Embodiment 2

[0046] The invention discloses another manufacturing method of a novel SMC composite material outdoor distribution box, such as figure 1 with image 3 As shown, on the basis of the main structure of the conventional SMC composite material, the surface of the glass fiber is metallized, and a certain amount of iron-based amorphous alloy powder and iron-based nanocrystalline alloy powder are added to the resin matrix to modify it. , through the pultrusion process to make a new type of SMC composite material slats and further assemble it into a new type of SMC composite material outdoor distribution box, such as Figure 5 shown.

[0047] The specific technical scheme is as follows:

[0048] The mass percentage of impregnating resin is obtained from the following components: 100 parts of resin matrix, 10 parts of filler, 4 parts of release agent, 3 parts of curing agent, 5 parts of low shrinkage agent, 1 part of antioxidant, and 5 parts of iron-based amorphous alloy powder 5 par...

Embodiment 3

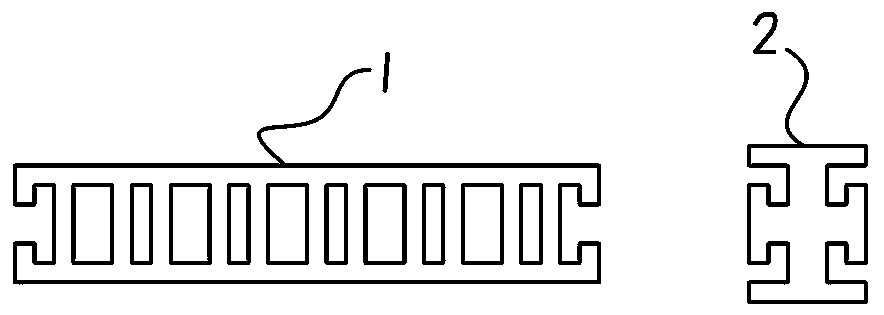

[0060] The invention discloses another manufacturing method of a novel SMC composite material outdoor distribution box, such as figure 2 with Figure 4 As shown, on the basis of the main structure of the conventional SMC composite material, the surface of the glass fiber is metallized, and a certain amount of iron-based amorphous alloy powder and iron-based nanocrystalline alloy powder are added to the resin matrix to modify it. , through the pultrusion process to make a new type of SMC composite material slats and further assemble it into a new type of SMC composite material outdoor distribution box, such as Figure 5 shown.

[0061] The specific technical scheme is as follows:

[0062] The mass percentage of impregnating resin is obtained from the following components: 100 parts of resin matrix, 10 parts of filler, 3 parts of release agent, 1 part of curing agent, 10 parts of low shrinkage agent, 2 parts of antioxidant, 4 parts of iron-based amorphous alloy powder 4 part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com