Electromagnetic water drainage system and washing machine

A drainage system, electromagnetic technology, applied in other washing machines, washing machine appliances, washing machines with containers, etc., can solve problems such as unreliability, and achieve the effects of reliable control, saving washing time, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

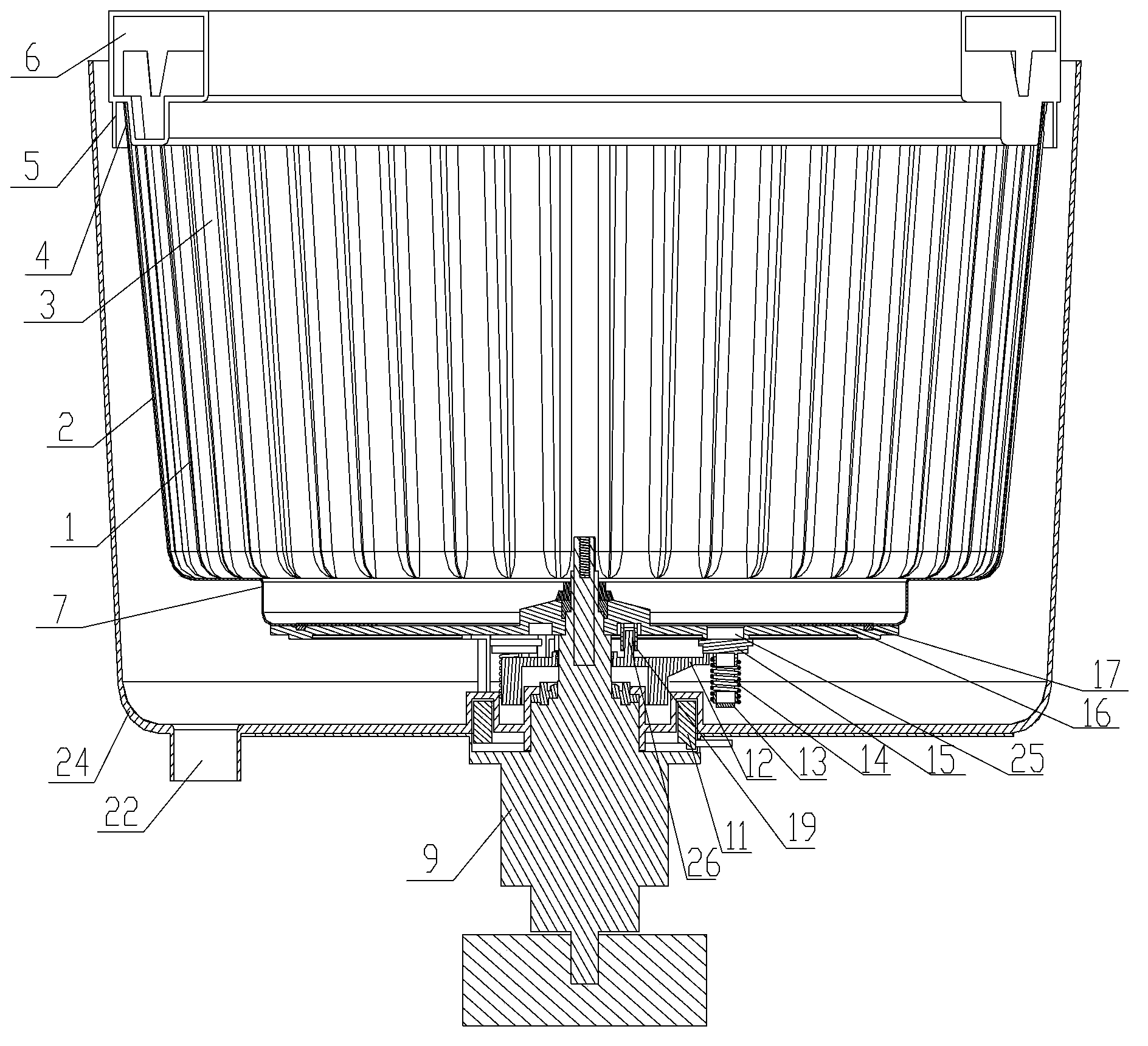

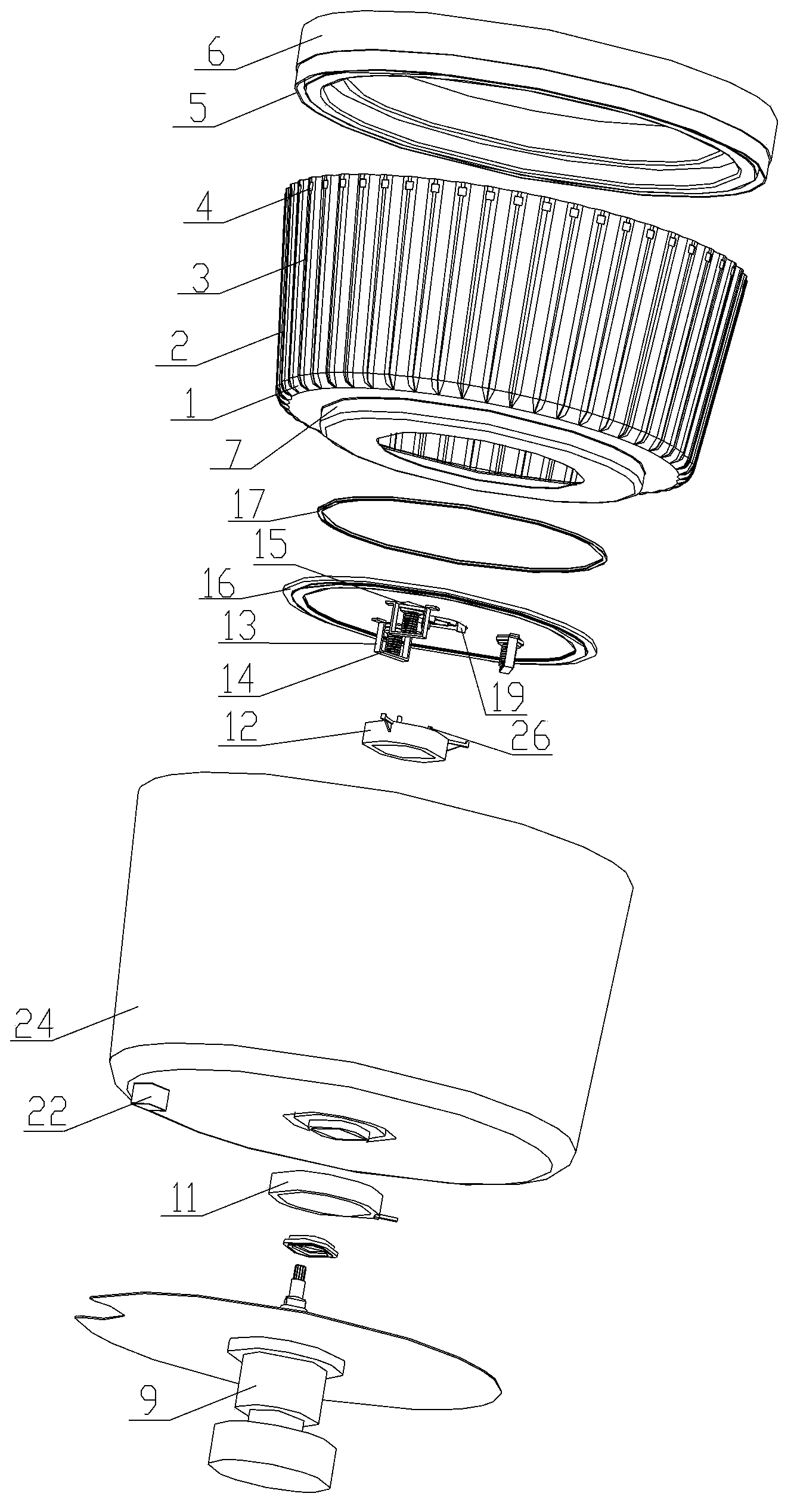

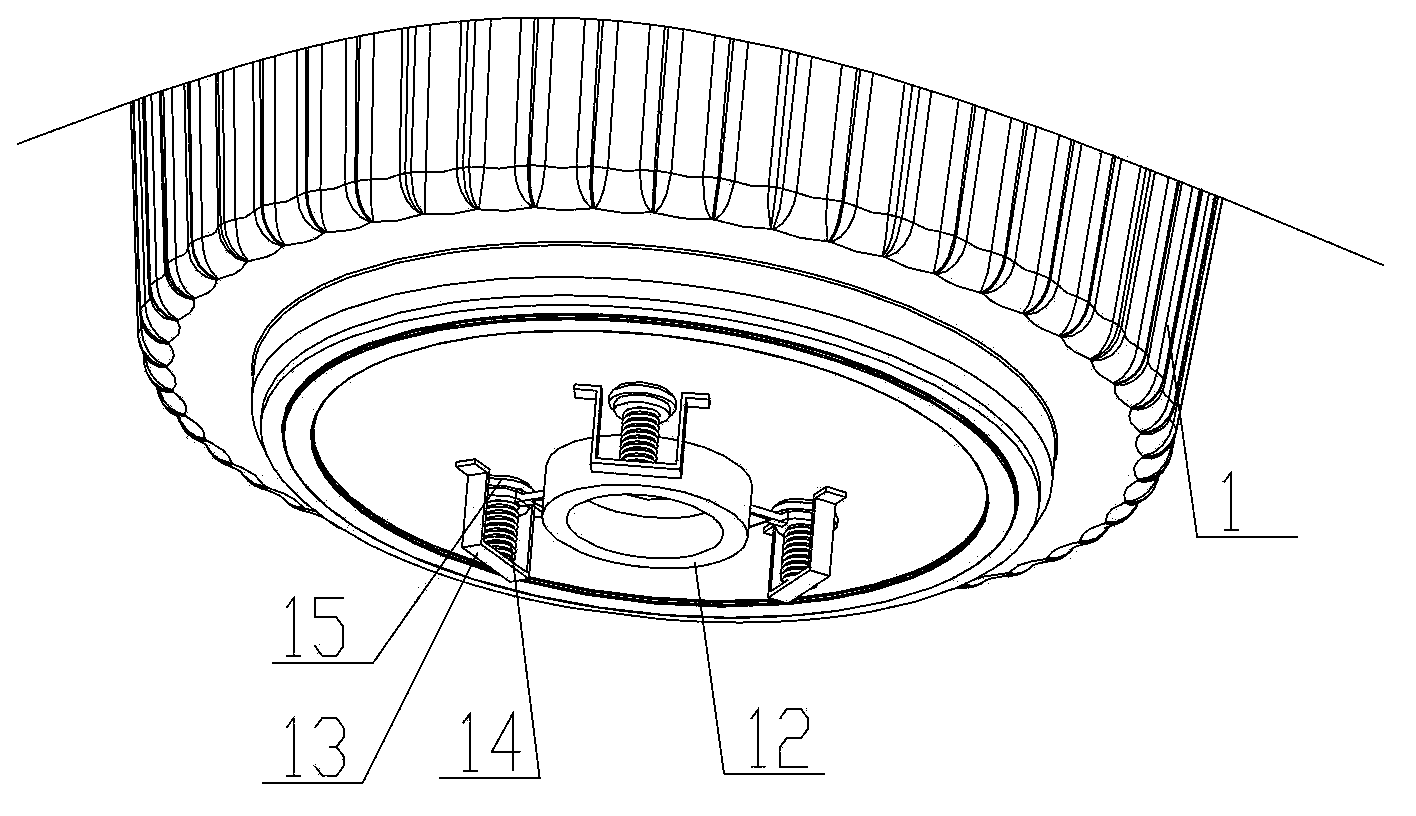

[0034] An electromagnetic drainage system, comprising a washing tub 1, said electromagnetic drainage system is fixedly connected to the lower part of the washing tub 1, and includes at least one drainage hole 25 at the bottom of the washing tub 1, and the lower part of each drainage hole 25 is provided for closing The sealing structure of the drainage hole 25, the sealing structure is opened by electromagnetic power control, and the sealing structure is also provided with a reset structure for controlling the sealing structure to return to the state of closing the drainage hole 25.

[0035] Such as figure 1 , figure 2 As shown, an electromagnetic drainage system is fixedly connected to the bottom of the washing tub 1, including at least one drainage hole 25 at the bottom of the washing tub 1, an annular metal ring 12, and an electromagnetic coil 11 located at the bottom of the metal ring 12 to provide electromagnetic power. , the seal cover 15 fixedly connected with the meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com