Method for repairing damaged drilled hole for in-situ leaching uranium mining through a plurality of layers of expanding materials

A technology for mining uranium by expansive materials and in-situ leaching, which is applied to drilling equipment and methods, drilling equipment, and earthwork drilling and mining, and can solve the problems of reduced uranium concentration in leachate and increased sediment volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

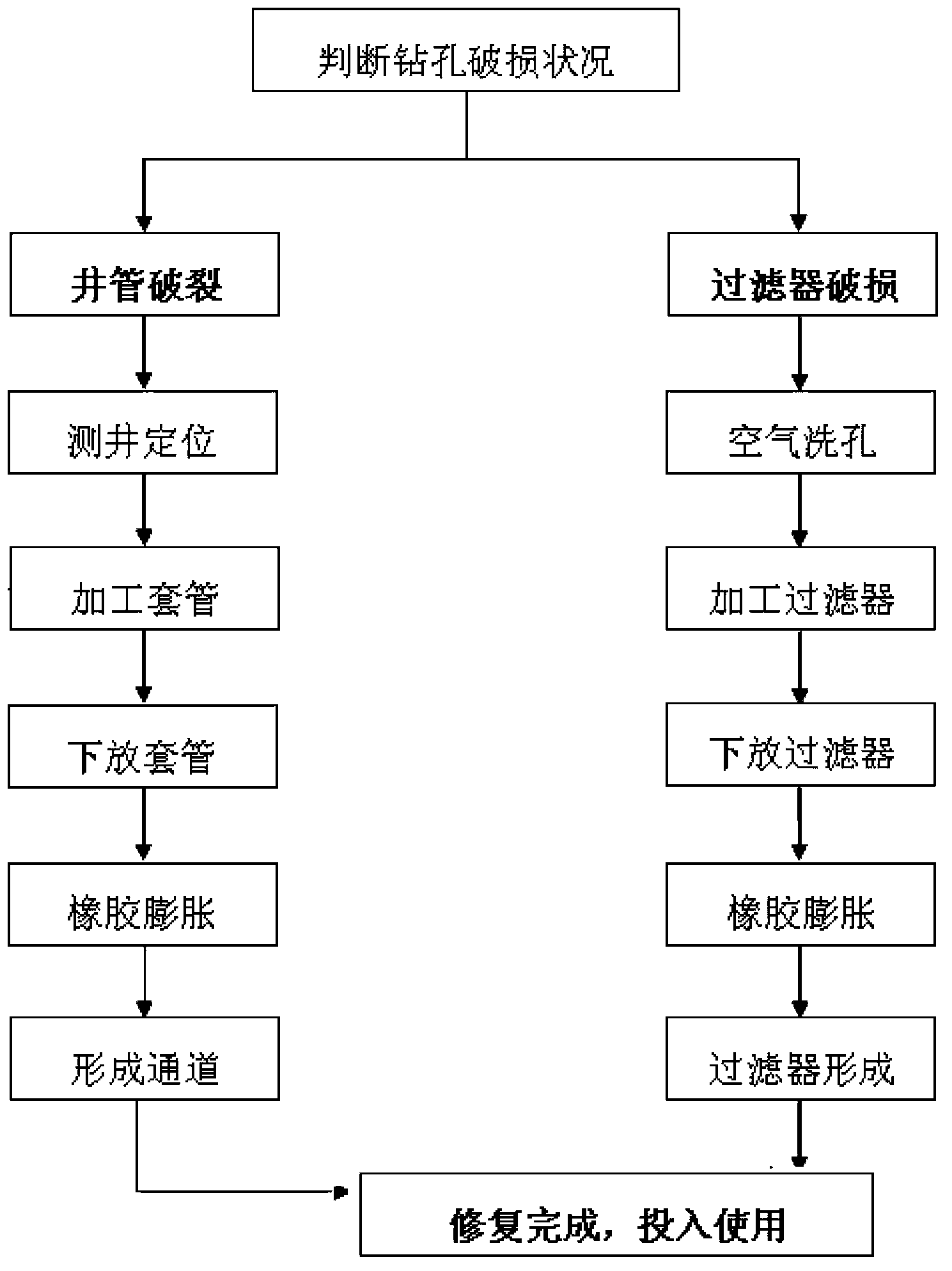

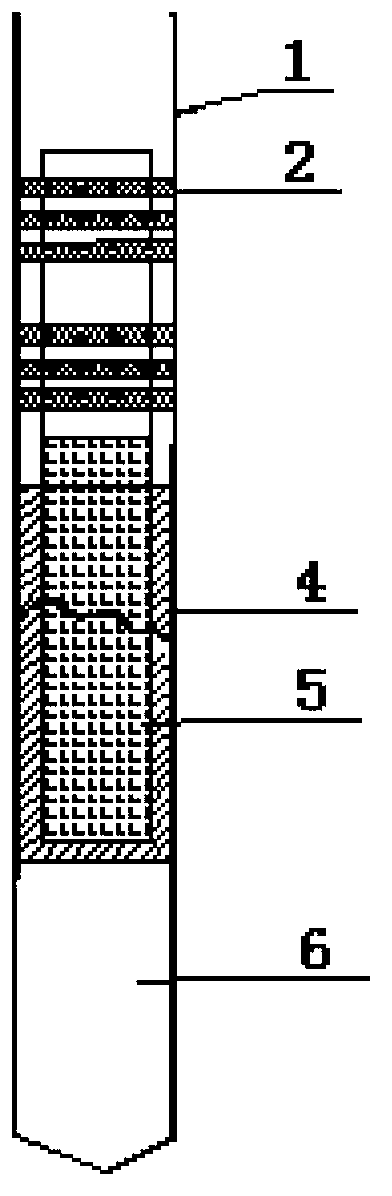

[0034] The technical scheme adopted in the present invention is: a method for repairing damaged boreholes in ground leaching mining of uranium with expansive materials, comprising the following steps in turn:

[0035] Step 1. Preliminary judgment is that the well pipe 1 is broken or the filter is damaged. The judgment standard is: the well pipe 1 is broken when the leachate is diluted, and the filter is broken when the amount of sediment increases;

[0036] Step 2. According to the judgment result of step 1, perform the following operations:

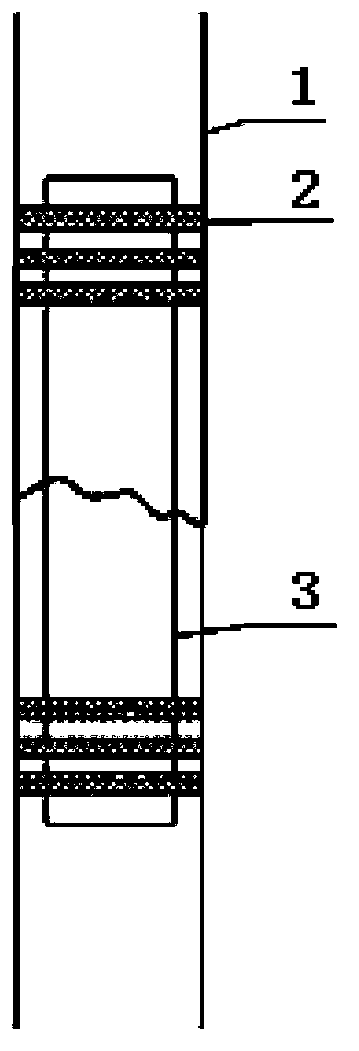

[0037] Step 2.1, in case the well pipe 1 breaks

[0038] Step 2.1.1, determine the location of the rupture of the well pipe 1 through well logging;

[0039] Step 2.1.2, using a plastic pipe with an inner diameter of 4 cm, a wall thickness of 10 cm, and a length of 6 m smaller than the well pipe 1 as the casing 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com