Large-dive-depth Kinston valve with small valve opening force

A valve opening force, sea valve technology, applied in the valve operation/release device, lift valve, valve details, etc., can solve the problem of not being able to open the valve, increasing the difficulty of selecting the driving equipment, increasing the volume and power requirements of the driving equipment, etc. Achieve the effect of increasing valve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

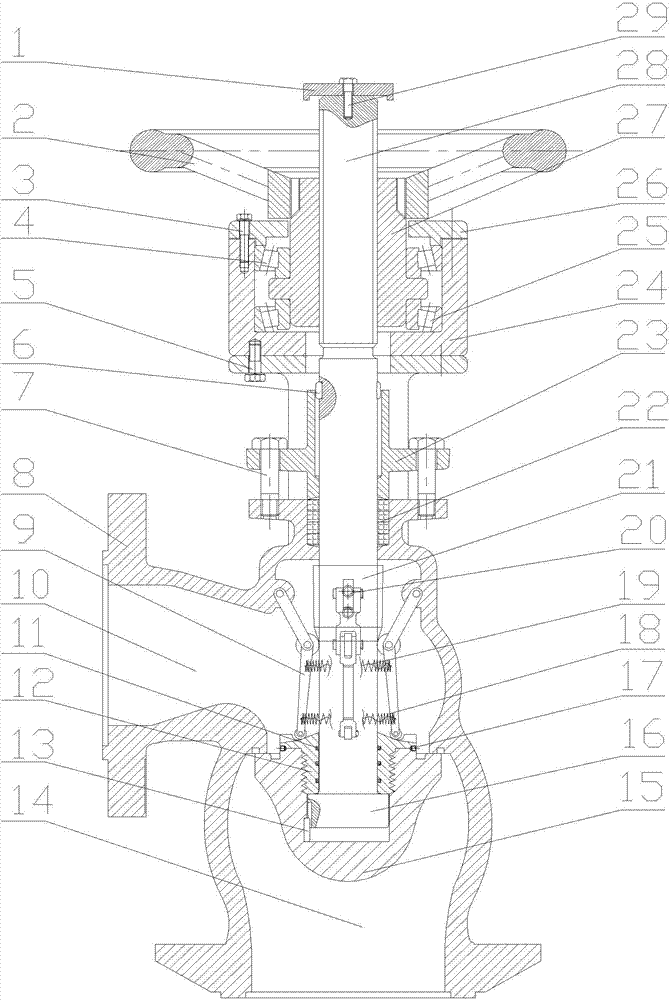

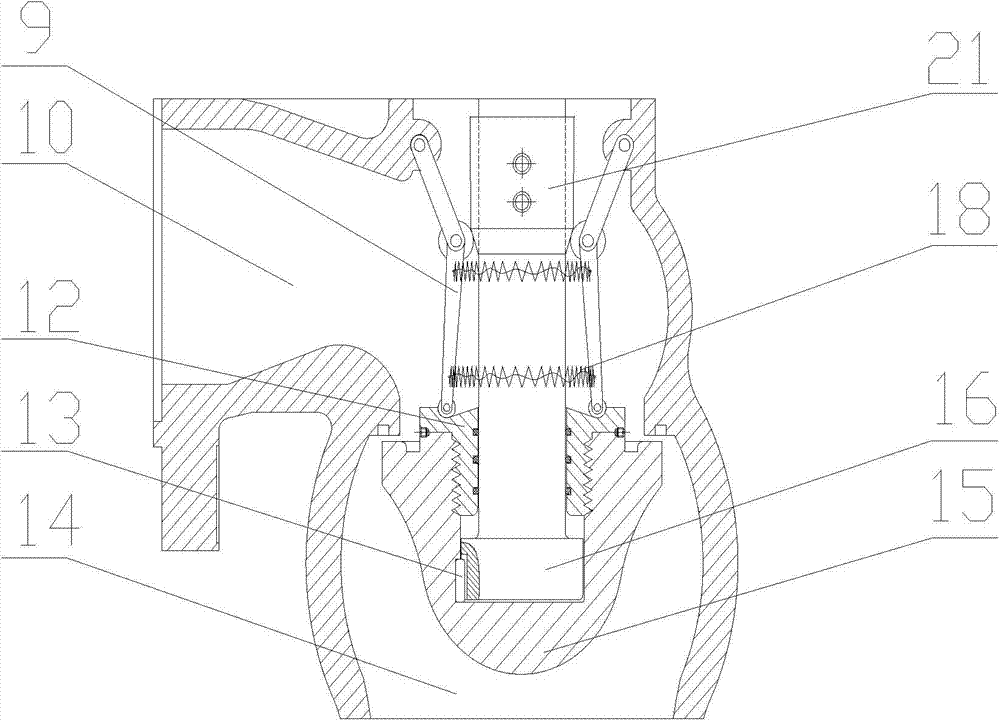

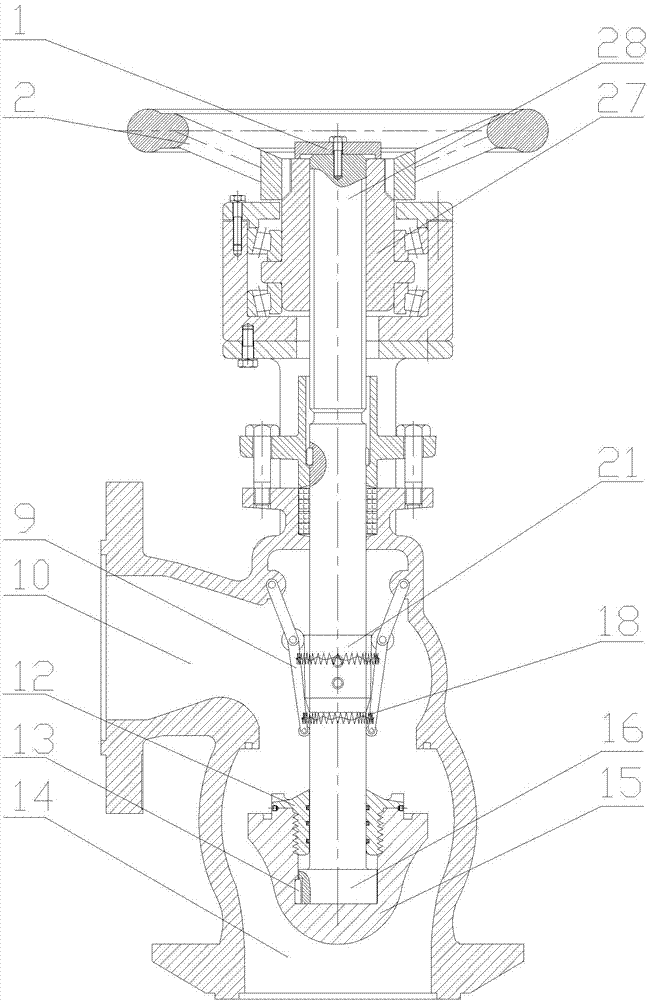

[0021] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0022] to combine figure 1 ~8, the present invention mainly includes hand wheel 2, bearing box part 3~5, 24~26, packing sealing part 7, 22~23, valve body 8, booster part 9, 18~21, valve stem part 1, 16 , 28, etc., valve head parts 11-13, 15-17.

[0023] The hand wheel 2 and the valve stem power block 27 are connected together by splines. The rotation of the hand wheel 2 drives the valve stem power block 27 to rotate. The upper and lower angle thrust bearings 4 and 25 limit the up and down movement of the valve stem power block 27. Bearing 4,25 is fixed by bearing housing 2, realizes the compression of upper and lower angular thrust bearings 4,25 by tightening six first bolts 3 and compressing bearing housing cover 26.

[0024] The bearing housing 2 and the valve body 8 are connected together by six second bolts 5 .

[0025] The packing sealing part includes two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com