An oil leakage prevention valve for power transformer oil tank

A power transformer, oil leakage prevention technology, applied in the direction of lift valve, valve device, engine components, etc., can solve the problems of damp insulation oil, transformer coil deformation, friction and switching torque, etc., to improve sealing performance, reduce The effect of switching torque and reducing frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

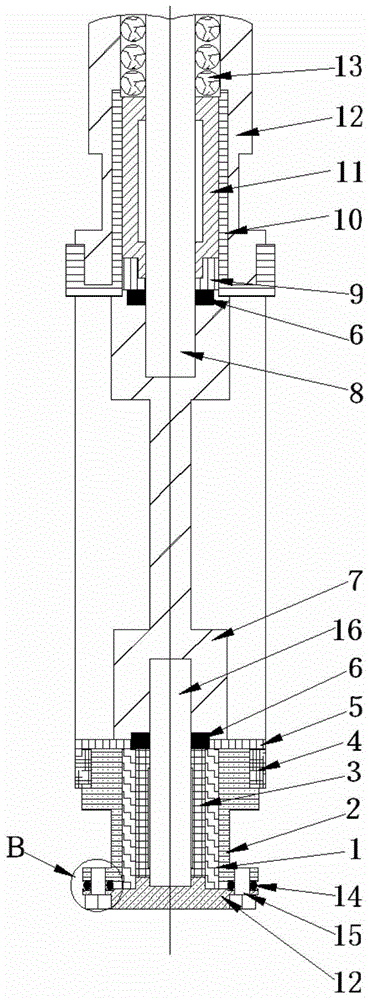

[0020] An anti-leakage valve for the oil tank of a power transformer, mainly composed of an upper valve stem 8, a butterfly plate 7, and a lower valve stem 16 connected in sequence, and flexible adjustment rings 6 are respectively fixed on the inner sides of the upper and lower ends of the butterfly plate 7, The outer side of the upper valve stem 8 is covered with an upper regulating bearing 11, the outer side of the lower valve stem 16 is covered with a lower regulating bearing 3, the outer casing of the upper regulating bearing 11 is equipped with an upper regulating ring 10, and the outer side of the lower regulating bearing 3 is covered by A lower adjustment ring 1 and an inner fastening ring 2 are sequentially set from inside to outside, the lower part of the inner fastening ring 2 is connected with the valve body 12 through bolts 15 , and the upper adjustment ring 10 is set in the valve body 12 . In order to better realize the present invention, a rigid adjustment ring 9 ...

Embodiment 2

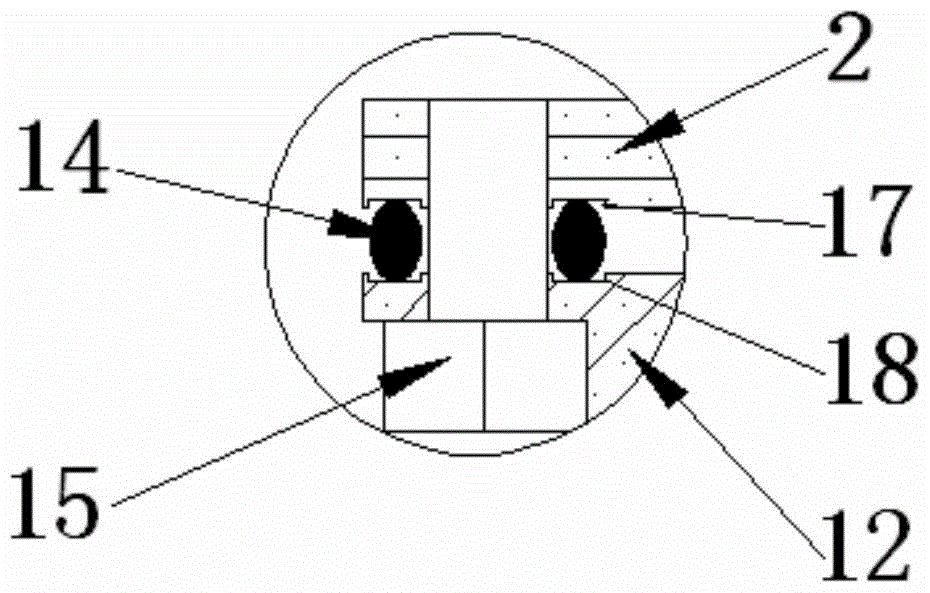

[0022] In order to better realize the present invention, on the basis of Embodiment 1, in this embodiment, a pad 5 is fitted outside the flexible adjustment ring 6 located at the lower end of the butterfly plate 7 . In order to better realize the present invention, an outer fastening ring 4 is fitted on the outer side of the cylindrical surface of the inner fastening ring 2 . In order to better realize the present invention, an upper groove 17 is provided on the surface where the inner fastening ring 2 is connected with the valve body 12 , and an O-ring 14 is fixed inside the upper groove 17 . The surface of the valve body 12 connected with the inner fastening ring 2 is provided with a lower groove 18 corresponding to the upper groove 17 . After the flexible adjusting ring 6 is set on the lower end of the butterfly plate 7 for sealing, the gasket 5 is placed outside the flexible adjusting ring to further seal the lower end of the butterfly plate 7 and effectively prevent oil l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com