Waste heat boiler for small waste incineration plant

A waste heat boiler and waste incineration technology, which is applied in the field of resources and environment, can solve the problems of waste of heat resources, the heat of small and medium-sized waste incineration has not been actively and effectively developed and utilized, and achieves the effect of ensuring cleanliness, convenient discharge and strong dust removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

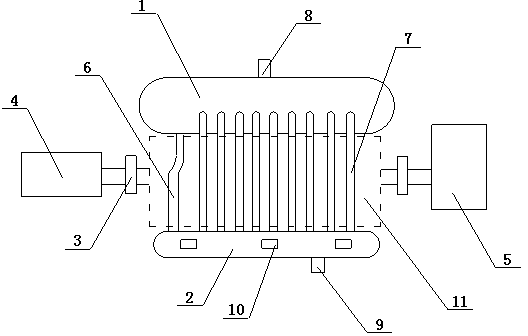

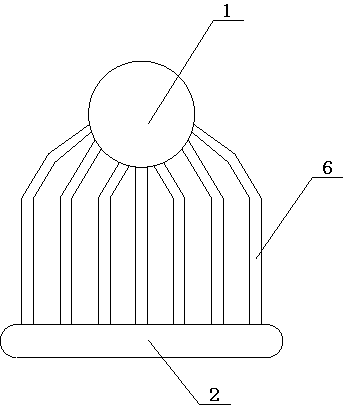

[0015] Such as figure 1 and figure 2 As shown, a waste heat boiler for a small waste incineration plant includes a waste heat boiler body 11, a steam drum 1, and a lower header 2. One end of the waste heat boiler body 11 is connected to an incinerator 4 through an expansion joint 3, and the waste heat boiler body 11 is another One end is connected to the dust collector 5 through the expansion joint 3, the end of the lower header 2 close to the incinerator 4 is connected to the steam drum 1 through the anti-coking tube 6, and the end of the lower header 2 close to the dust collector 5 is connected to the steam drum 1 through the convection heat absorption tube bundle 7. Package 1 is connected, and the convective heat-absorbing tube bundle 7 includes a row of bare tubes and a row of finned tubes, and the rows of bare tubes and finned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com