Anti-drifting rain electric dust removal thin roof ventilator

A kind of ventilator, thin technology, applied in the direction of ventilation system, roof drainage, space heating and ventilation, etc., can solve the problems such as difficult to clean dust, drifting rain, easy to accumulate dust, etc., to improve drainage capacity, improve the production environment, avoid The effect of standing water seepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiment of the present invention is described in further detail below in conjunction with accompanying drawing:

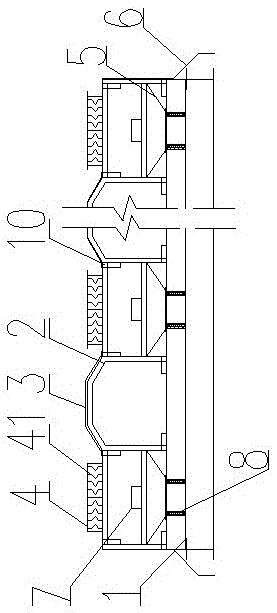

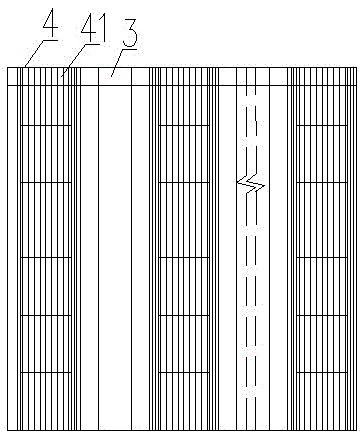

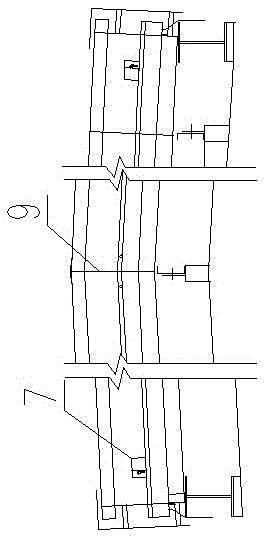

[0025] As shown in the figure, the anti-drifting rain electric dust-cleaning thin roof ventilator includes ventilator base 1, ventilator frame 2, rain shield 3, rain director 4, thin plate 41, sump 5, flashing plate 6, eccentric wheel Motor 7, elastic support 8 and notch 10. The ventilator base 1 is installed on the ventilator steel foundation on the truss of the factory building, and the herringbone ventilator frame 2 is installed on the ventilator base 1; On the device frame 2, a notch 10 in the vertical direction is provided at the junction of the rain shield 3 and the rain director 4. The rain director 4 is composed of a plurality of thin plates 41 spaced apart from each other. The thin plates 41 are "" shaped broken line channels. The bottom of each column of rain director 4 is provided with a sump 5 installed on the ventilator frame 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com