Kernel learning monitoring method for penicillin production process under unequal-length batch conditions

A production process, penicillin technology, applied in the direction of electrical program control, comprehensive factory control, etc., can solve the problems of inconsistent data lengths, limit the scope of application of traditional methods, etc., to improve monitoring effects, reduce complexity, and strengthen modeling capabilities. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

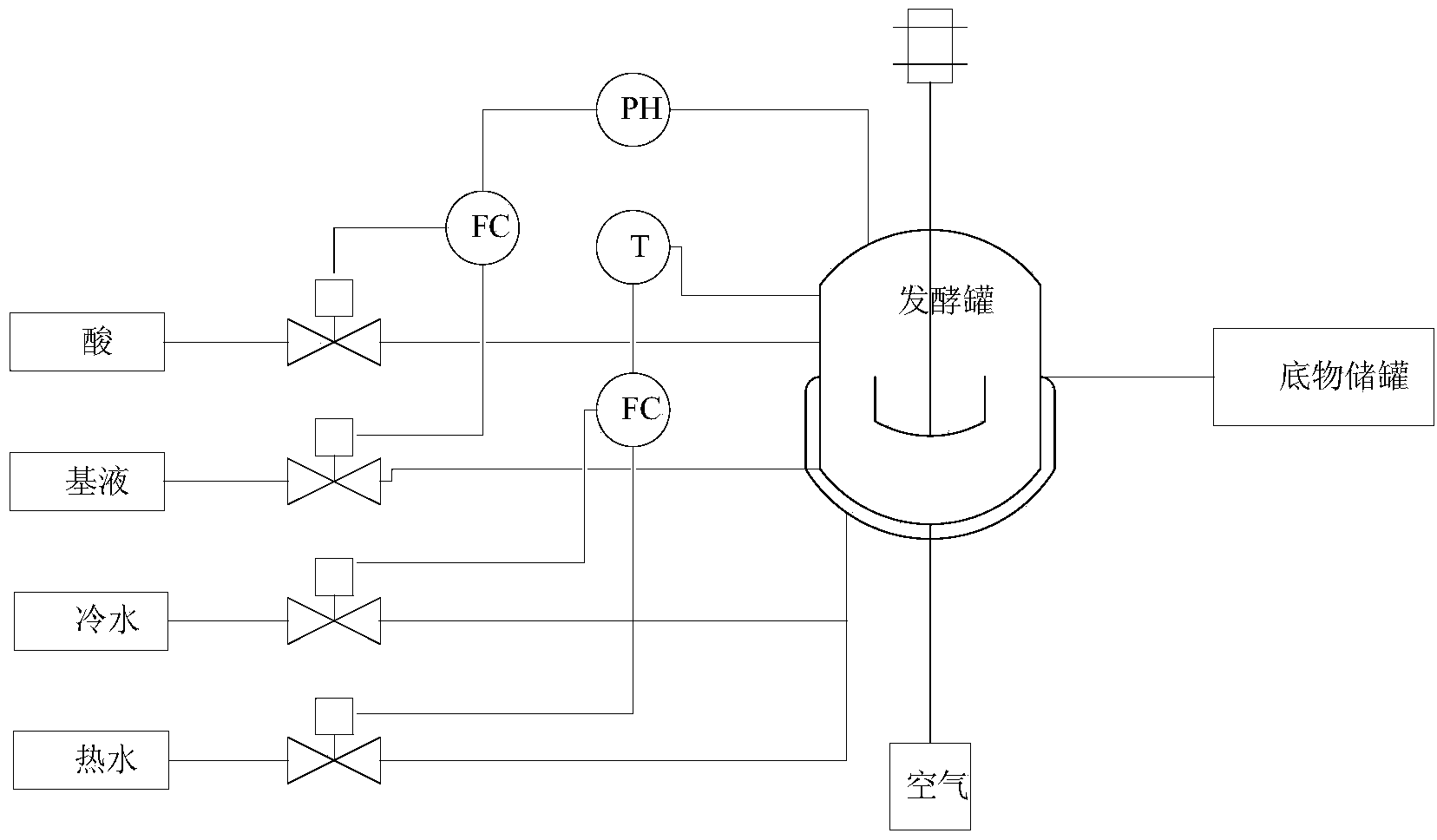

[0016] The penicillin production process nuclear learning monitoring method under a kind of unequal length batch condition of the present invention comprises the following steps:

[0017] Step 1: Use the distributed control system to collect the data of the penicillin production process to form a training sample set for modeling: i=1,2,…,I, among them, R is a set of real numbers, which means X i Obey K i ×J two-dimensional data distribution, I is the batch information of the data, K i is the number of sampling data points of the i-th batch, J is the number of variables, and these data are stored in the historical database;

[0018] Step 2: Arrange each data matrix along the time point direction to obtain a new data matrix, and preprocess and normalize it, that is, make the mean value of each process variable zero and the variance 1, and obtain a new data matrix The data matrix set of is

[0019] Arrange the matrix composed of each batch of data along the direction of ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com