Electromagnetic tomography nondestructive inspection device for severe fault of rail and method thereof

A non-destructive testing, electromagnetic layer technology, applied in the direction of material magnetic variables, etc., can solve problems such as failure to achieve the depth and location of rail damage, small detection range, and detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the present invention are described in detail below in conjunction with the accompanying drawings:

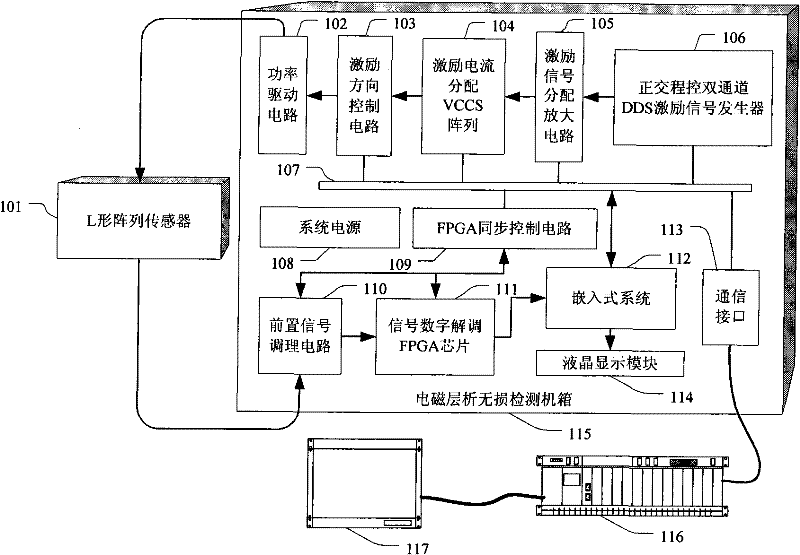

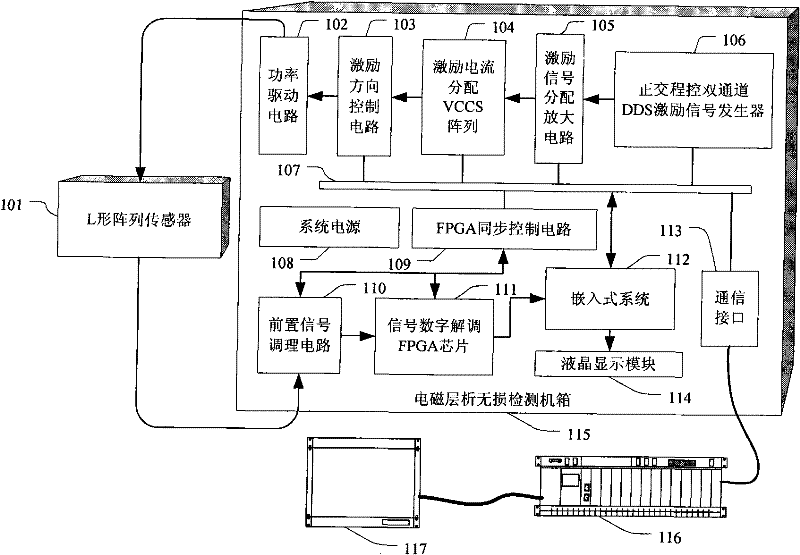

[0015] Electromagnetic tomography non-destructive testing device for severe rail damage according to the present invention, such as figure 1 As shown, it includes an L-shaped array sensor 101 , an electromagnetic tomography nondestructive testing case 115 , a flaw detection monitoring and recording computer 116 , and a flaw detection monitoring liquid crystal panel 117 .

[0016] Among them, the electromagnetic tomography nondestructive testing chassis 115 includes a power drive circuit 102, an excitation direction control circuit 103, an excitation current distribution VCCS array 104, an excitation signal distribution amplification circuit 105, and an orthogonal program-controlled dual-channel DDS (Direct Digital Dynthesizer, direct frequency synthesizer ) excitation signal generator 106, bus 107, system power supply 108, FPGA synchronous control circuit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com