BOM change management method

A management method and administrator's technology, applied in the field of BOM change management, can solve problems such as steel inventory backlog, production stoppage, production impact, etc., and achieve the effects of reducing adverse effects, improving accuracy, and avoiding adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

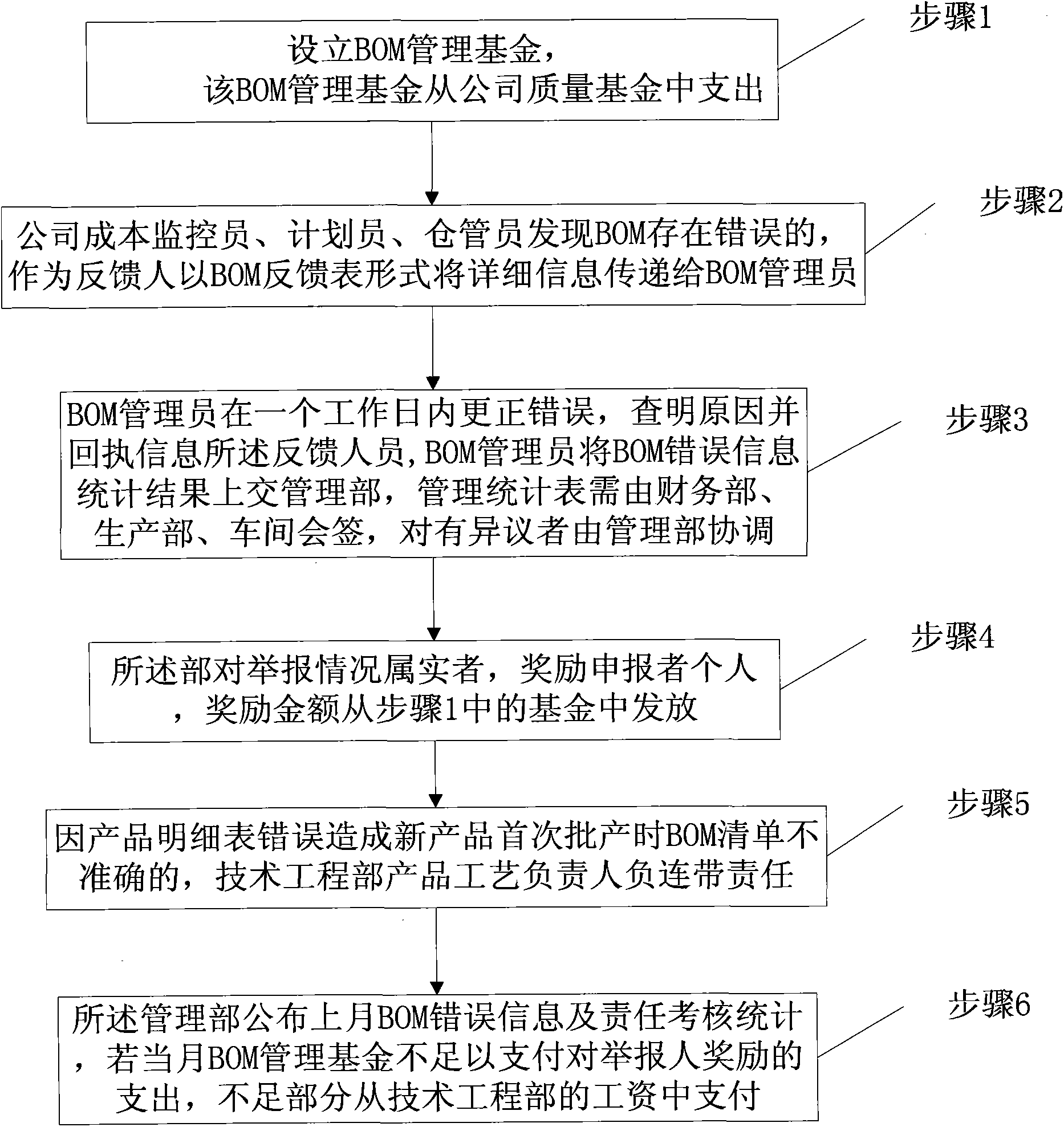

Method used

Image

Examples

Embodiment 1

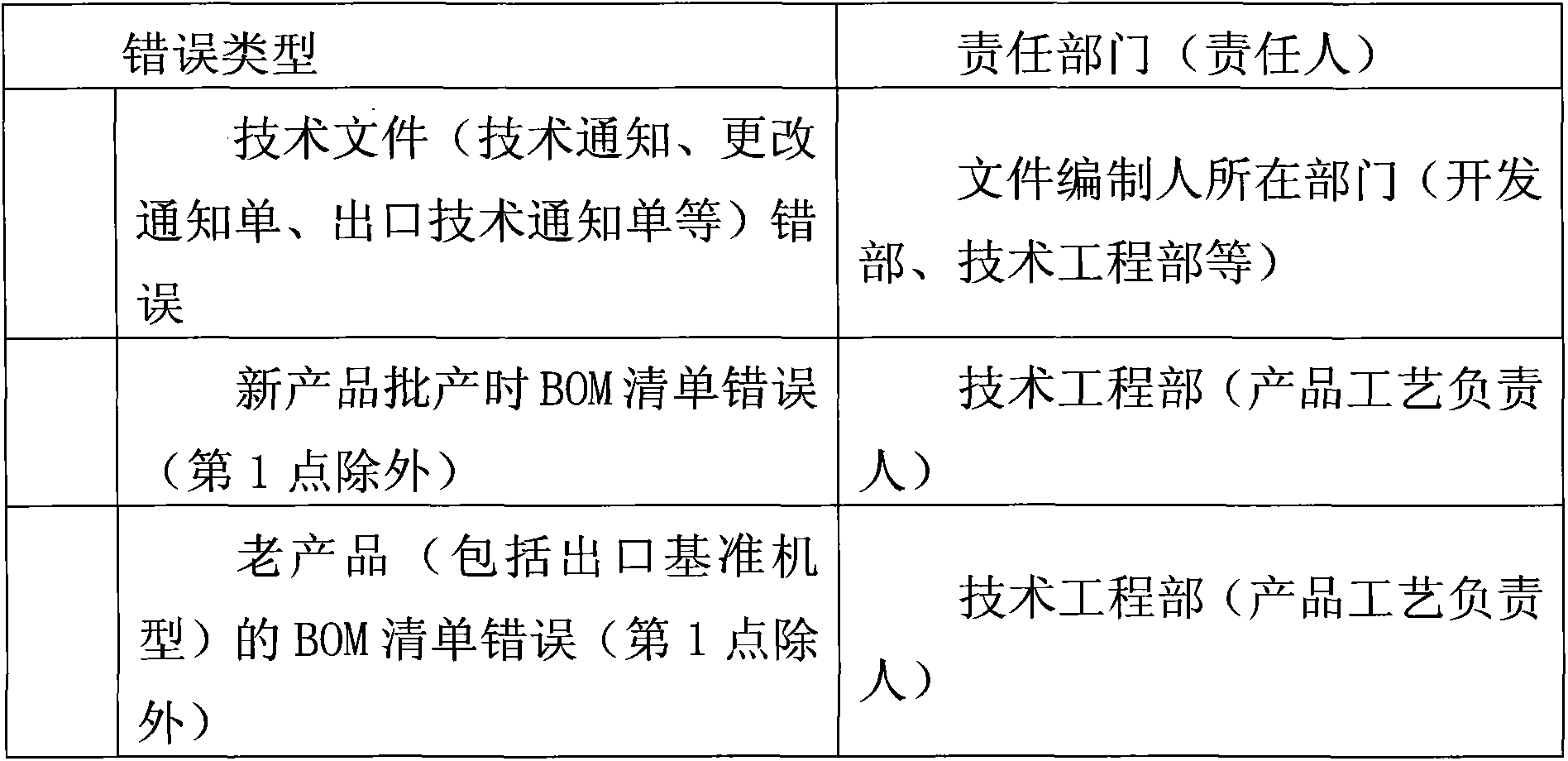

[0033] Responsibility definition:

[0034] The technical engineering department is the responsible department of the company's BOM management; the relevant responsibilities are defined as shown in Table 1.

[0035] Table 1

[0036]

[0037]

[0038] Assessment method:

[0039] Set up a BOM management fund (600 yuan / month) and spend it from the company's quality fund. The company's cost monitors, planners, material pickers (feeders), warehouse managers and other relevant personnel are all responsible for monitoring and maintaining the accuracy of the BOM. If it is found that there is an error in the BOM, the detailed information will be passed to the BOM administrator in the form of a BOM feedback form. The BOM administrator corrects the error within one working day, finds out the reason and replies to the information feedback personnel (for the BOM error caused by the documents of the development department and other departments, the responsible department should also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com